Flexographic Printing vs Offset Printing: Which Is Better for Carton Packaging?

Discover why flexographic printing is the best choice for carton packaging in 2025. Learn its advantages, applications, and why Giant is the top supplier.

Discover why flexographic printing is the best choice for carton packaging in 2025. Learn its advantages, applications, and why Giant is the top supplier.

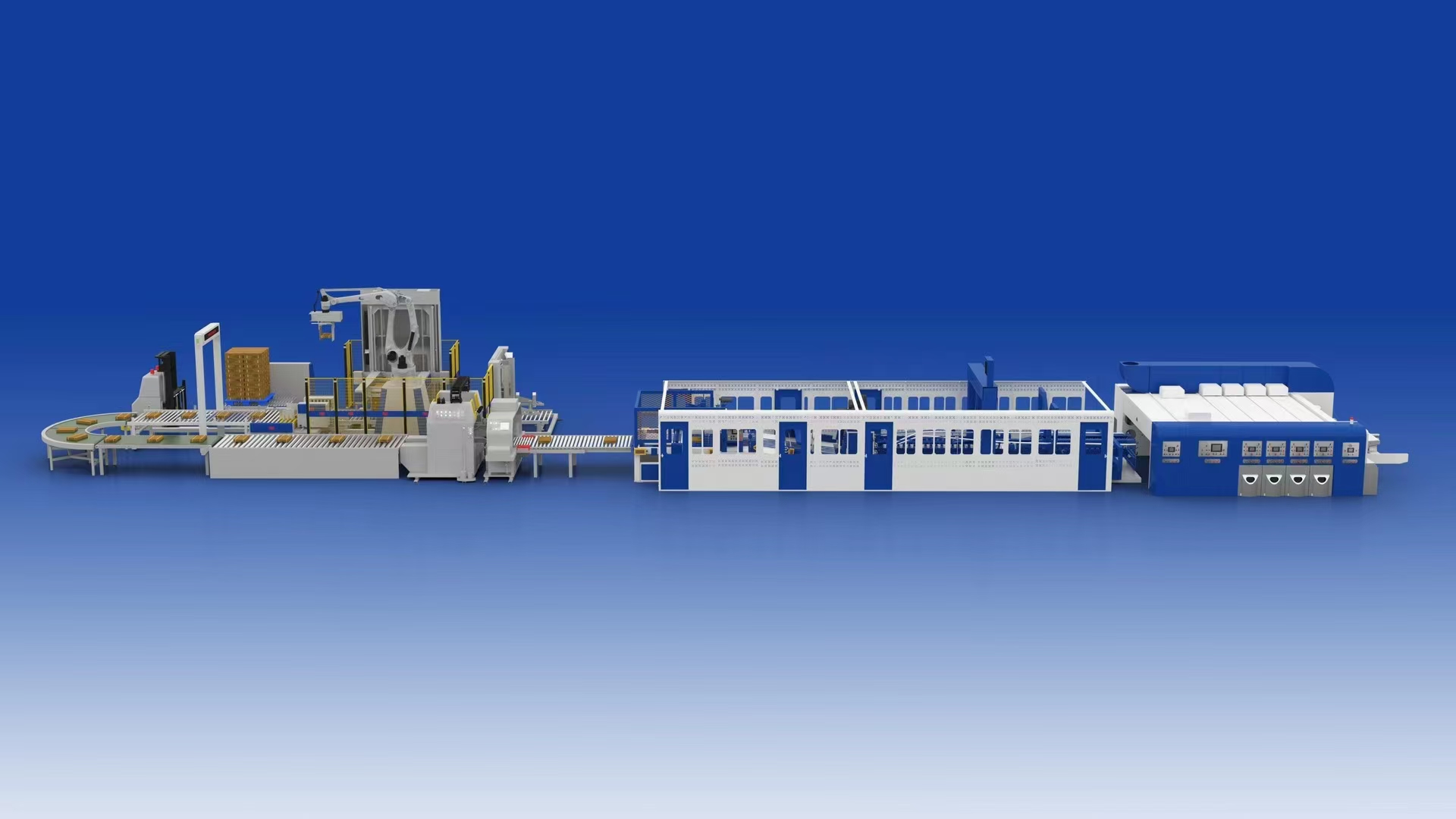

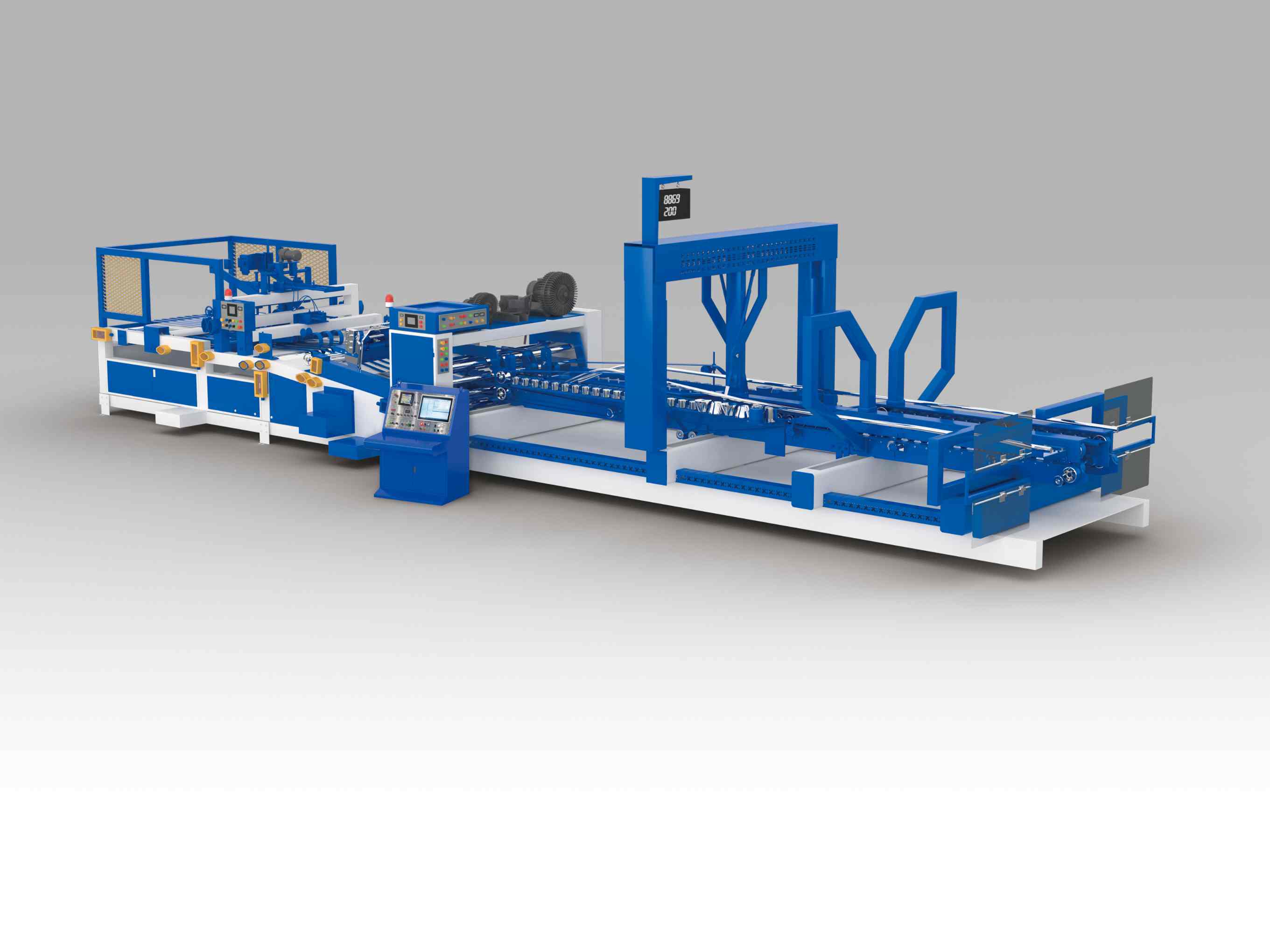

Discover how a flexo printer slotter die cutter works in 2025. Learn its functions, advantages, applications, and why choosing Giant can improve your packaging production efficiency.

Giant supplies advanced flexographic printing machines for corrugated cartons and pizza boxes. Achieve cost savings and consistent print quality.

Learn the top 10 features to look for in a modern flexo printing machine. Giant offers high-quality flexographic printers for pizza boxes, cartons, and food packaging.

Flexographic printing machines offer speed, quality, and cost savings for pizza box production. Giant provides high-performance flexo printers for food packaging.

Choose the best flexographic printing machine for corrugated boxes with Giant. High-quality flexo printers for pizza boxes, cartons, and packaging.

Looking for the best printing machine for corrugated packaging? Discover the differences between flexographic, digital, and offset printing machines, plus how to choose the right solution for your packaging line in 2025.

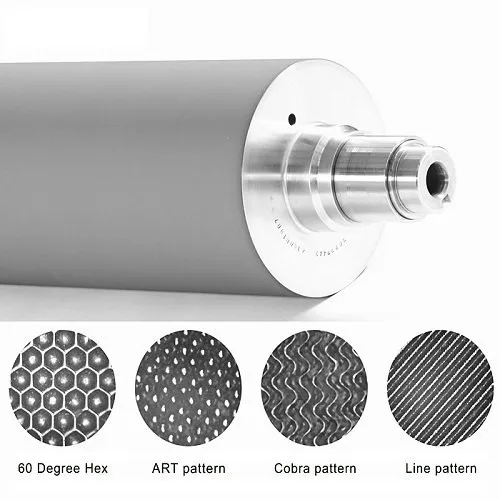

For print professionals, particularly in the corrugated packaging industry, the ceramic anilox roller is the linchpin of precise ink transfer and consistent print quality. Its microscopic cells are designed to accurately meter and deliver ink, directly influencing color vibrancy, image crispness, and production efficiency. To ensure optimal performance and extend the lifespan of these critical components, understanding and implementing proper cleaning and maintenance protocols are paramount. Neglecting anilox care can lead to clogged cells, reduced ink transfer volume, inconsistent print results, and increased costs .

In the dynamic world of consumer goods and e-commerce, corrugated packaging has evolved far beyond its primary role of protection. Today, it's a powerful marketing tool, a brand ambassador, and a crucial element in the overall customer experience. Especially with the rise of digital printing equipment for corrugated cardboard, the possibilities for innovative and impactful designs are endless.