How to Choose the Best Flexographic Printing Machine for Corrugated Boxes

In today's competitive packaging industry, corrugated boxes are more than just shipping containers—they have become an essential marketing tool. From pizza boxes to branded e-commerce cartons, businesses rely on high-quality printing to make their products stand out. Choosing the best flexographic printing machine for corrugated boxes can significantly improve print quality, production speed, and cost efficiency.

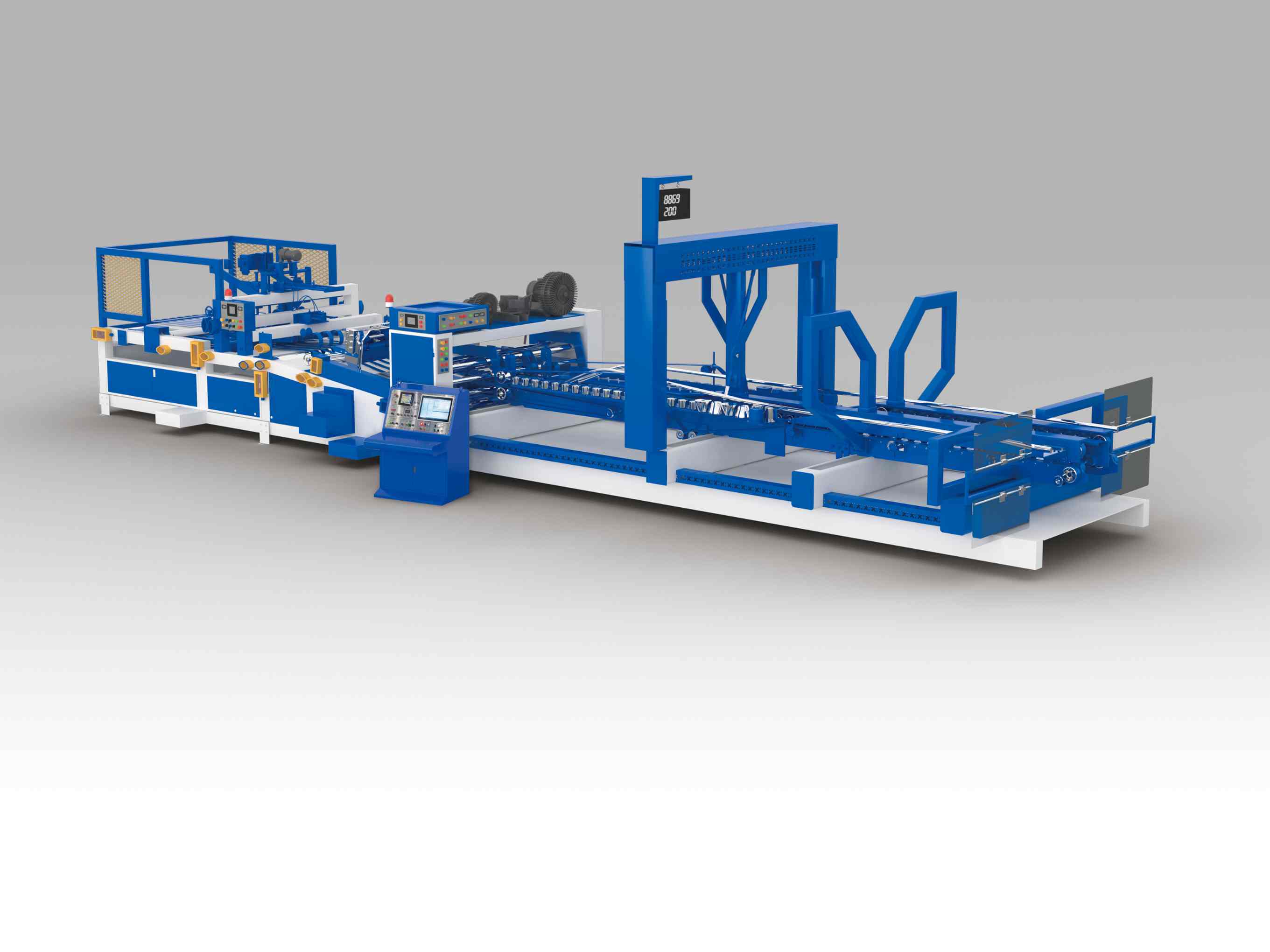

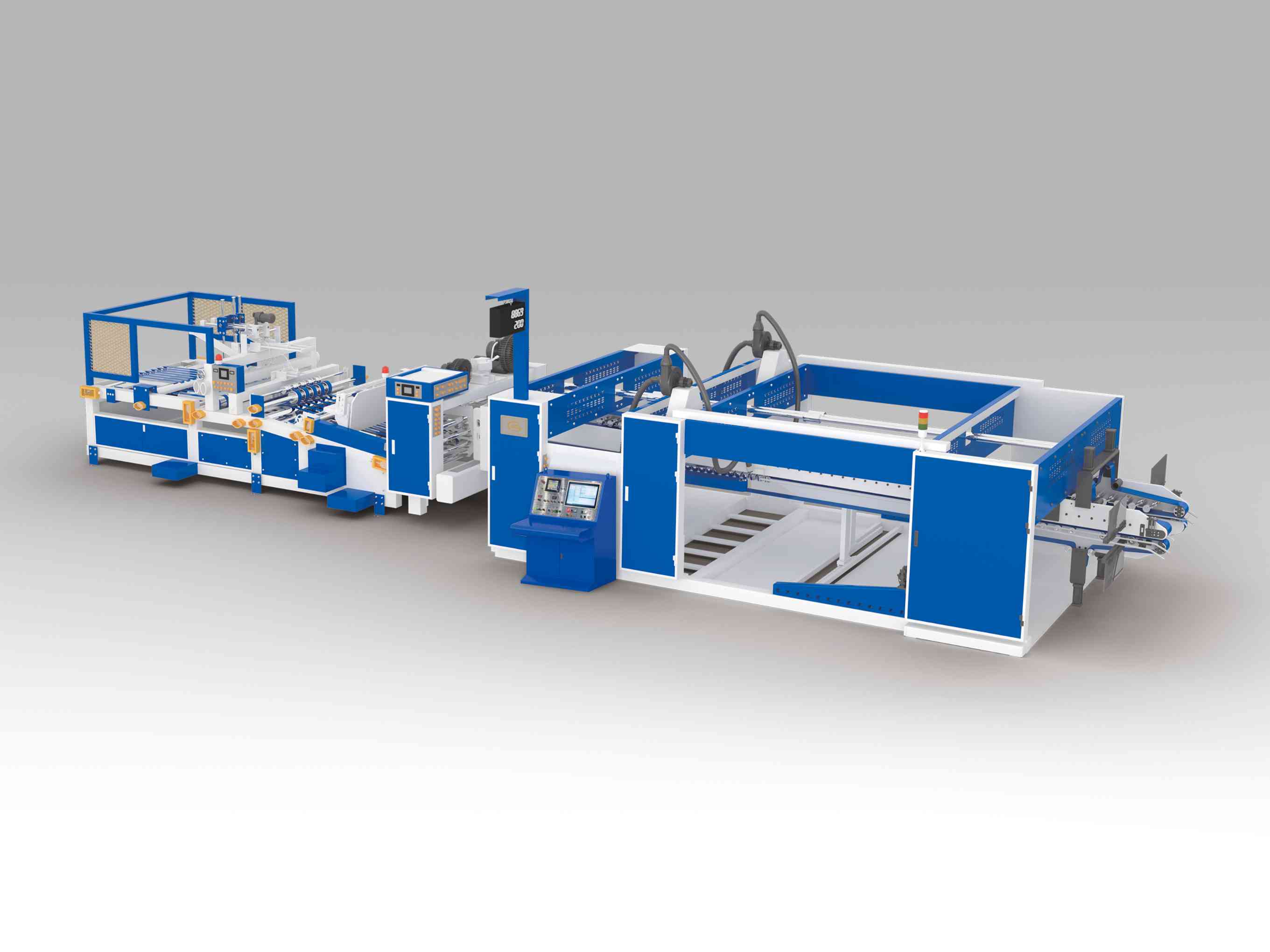

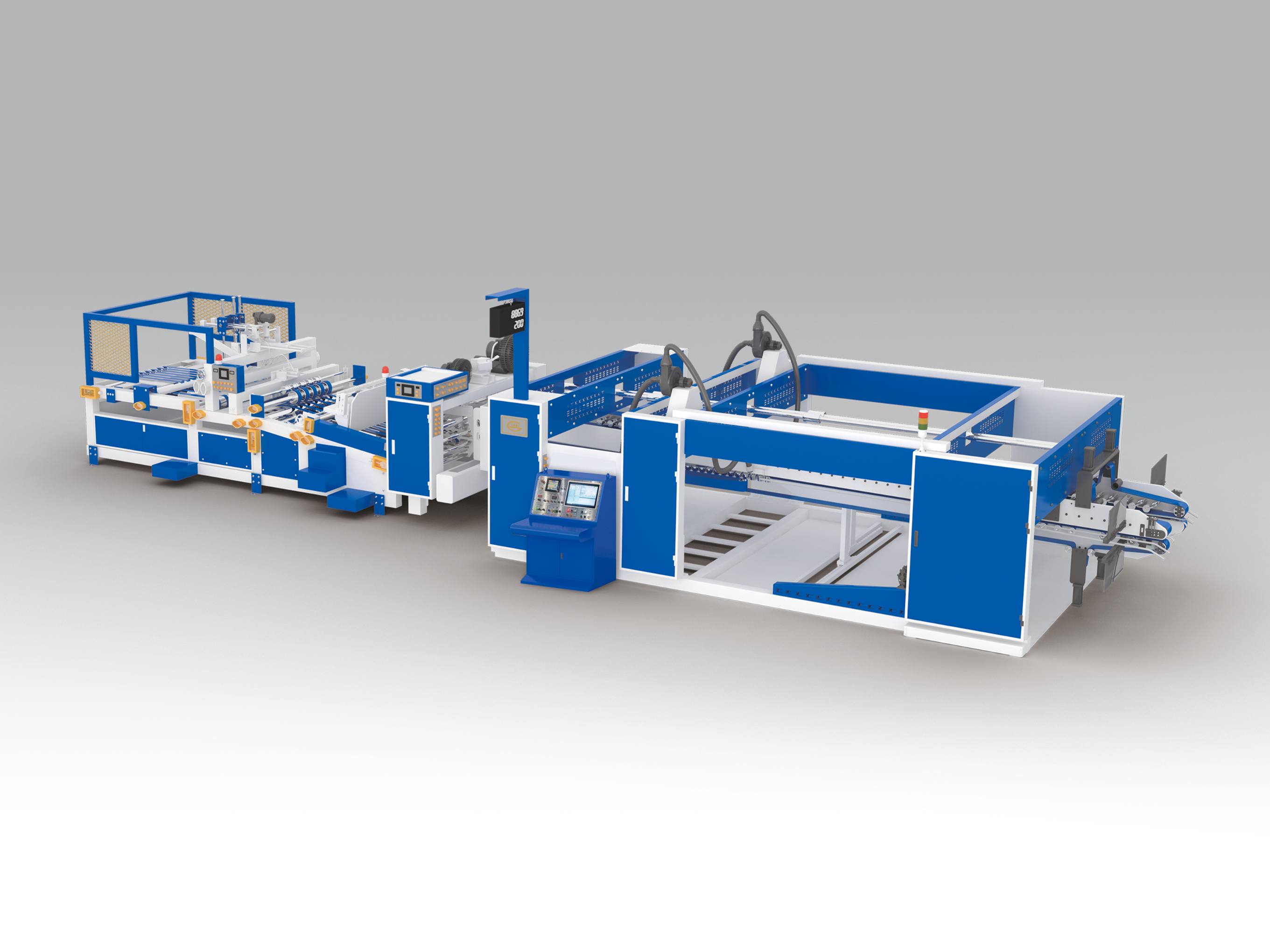

As a leading supplier of flexo printing machines and corrugated box making equipment, Giant has helped numerous packaging manufacturers upgrade their production lines with reliable, efficient, and versatile machines. In this guide, we'll walk you through the key factors to consider when selecting the right machine for your business.

1. Understand What a Flexographic Printing Machine Does

A flexographic printing machine—often referred to as a flexo press—is designed to print high-quality graphics on a variety of substrates, including corrugated cardboard, kraft paper, and coated boards. Using flexible relief plates, the machine applies ink directly to the surface, making it ideal for corrugated box printing and pizza box printing.

Key advantages of flexographic printing include:

- High-speed printing for mass production

- Versatility in handling different substrates

- Cost efficiency for large runs

- Eco-friendly printing options with water-based inks

2. Determine Your Printing Requirements

Before investing in a machine, clearly define your production needs:

- Box Size and Format – Are you printing small pizza boxes or large shipping cartons?

- Print Colors – Will you need two-color, four-color, or six-color printing?

- Print Quality – Do your customers require high-definition graphics or simple text and logos?

- Production Volume – How many boxes do you need to print per day?

By understanding these factors, you can choose a machine that matches your operational goals.

3. Choose the Right Printing Width and Speed

The printing width determines how large the printed area can be, while the machine speed affects production efficiency.

- Small to Medium Runs – A compact corrugated box flexo printer is enough for small manufacturers.

- Large-Scale Production – High-speed automatic machines with wide printing widths are ideal for big packaging plants.

Giant’s flexographic printing machines are available in various widths and speeds to meet the needs of both small businesses and large factories.

4. Consider Printing Quality and Registration Accuracy

High-quality corrugated box printing depends on registration accuracy—the machine's ability to align colors perfectly.

- Basic Packaging – For simple logos and text, a semi-automatic flexo printer may be sufficient.

- High-Graphics Packaging – For retail-ready boxes and pizza boxes with branding, choose a machine with precise color registration and fine resolution.

At Giant, we equip our machines with advanced registration control systems to ensure sharp, vibrant prints on every box.

5. Evaluate Ink and Drying Systems

Ink compatibility is another critical factor:

- Water-based inks – Environmentally friendly and widely used for food packaging.

- UV inks – Offer faster curing and vibrant colors, suitable for premium packaging.

A good drying system ensures the ink dries quickly without smudging. Giant's flexo printers use efficient hot-air or infrared drying systems to support continuous, high-speed production.

6. Look for Easy Operation and Maintenance

Downtime can be costly, so choose a machine that is:

- User-friendly with intuitive controls

- Easy to clean with quick-change printing plates

- Low-maintenance to minimize production interruptions

Giant designs its machines for operator convenience, reducing setup times and increasing productivity.

7. Check for Automation Features

Modern flexographic printing machines come with advanced automation, such as:

- Automatic plate mounting

- Auto ink control

- Touchscreen operation

- Quick job changeover

These features not only save time but also ensure consistent printing quality.

8. Consider After-Sales Support and Spare Parts

A reliable supplier is as important as the machine itself. Look for:

- Comprehensive training programs

- Fast spare parts availability

- Technical support for troubleshooting

When you choose Giant, you're not just buying a machine—you're gaining a long-term partner who supports your production success.

9. Factor in Budget and ROI

While price is important, don't choose the cheapest machine without considering its lifespan, productivity, and maintenance costs. A slightly higher upfront investment in a high-quality machine can pay off through:

- Reduced waste

- Lower downtime

- Better print quality

Giant's flexo printing machines are built for durability and cost efficiency, ensuring you achieve a strong return on investment.

10. Think About Future Expansion

Your current needs may grow in the next few years. Select a machine that can be upgraded or adapted for higher production or different printing applications—such as printing on paper bags, labels, or other packaging materials.

Conclusion

Choosing the best flexographic printing machine for corrugated boxes is a strategic decision that can transform your packaging business. By considering printing requirements, machine specifications, ink systems, automation features, and after-sales support, you can invest in a solution that delivers long-term value.

As a trusted manufacturer and supplier, Giant offers a full range of flexo printing machines and corrugated box making equipment tailored to different business needs—from small pizza box printing workshops to large-scale packaging factories. With our expertise, durable machines, and dedicated support, we help you achieve exceptional printing quality and efficiency.