How a Flexo Printer Slotter Die Cutter Works: Complete Guide 2025

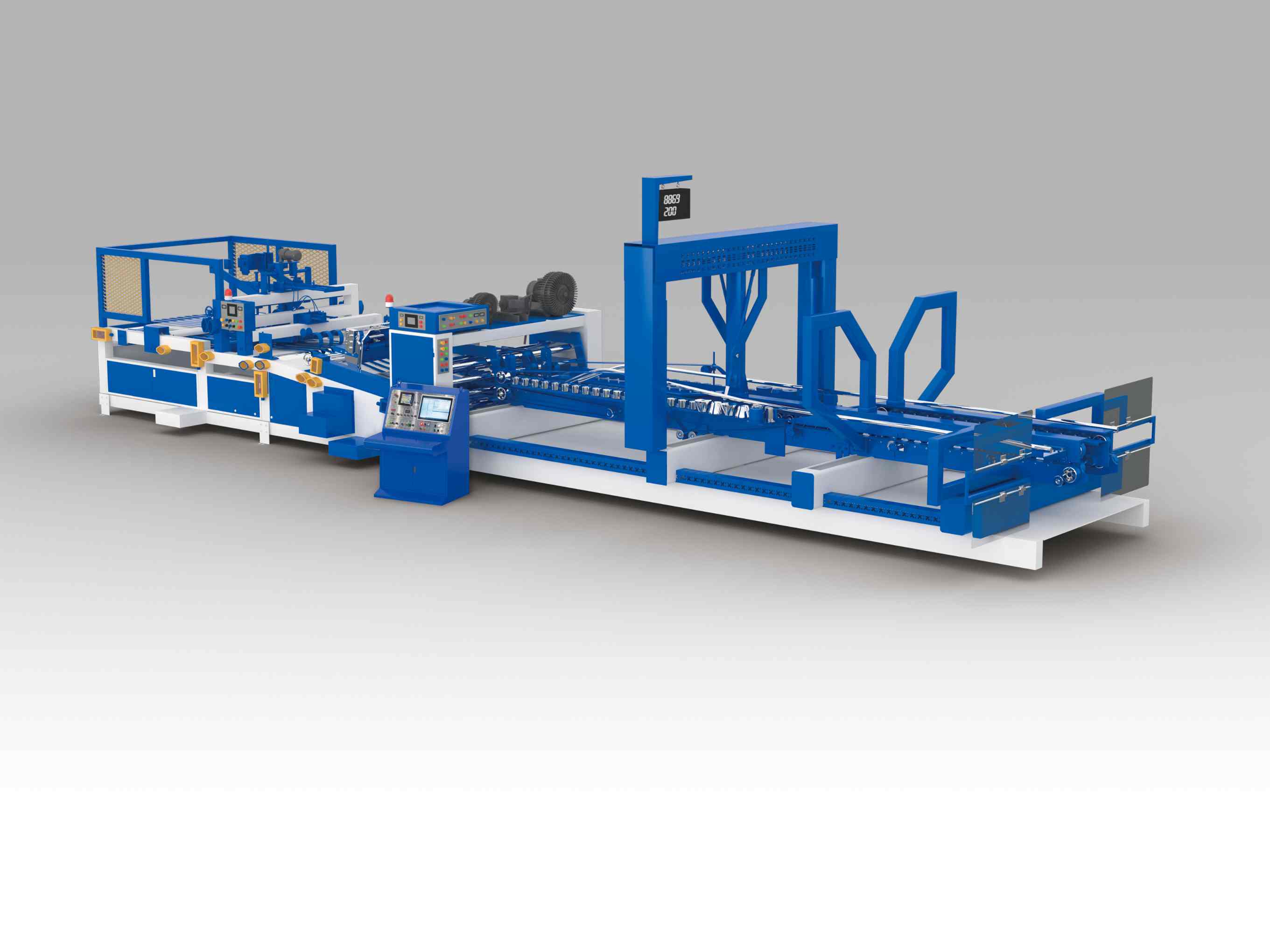

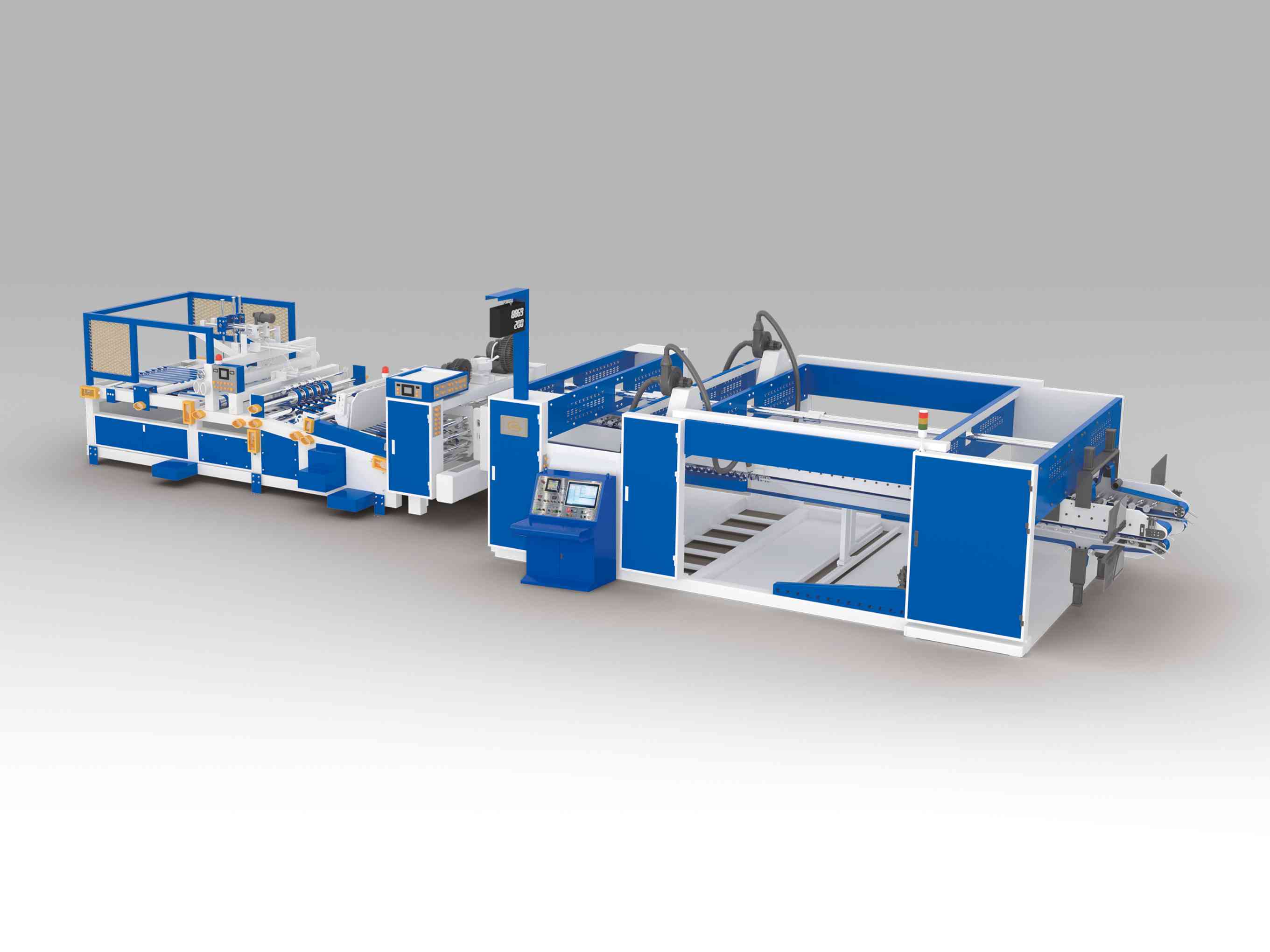

In the ever-evolving world of packaging, efficiency and precision are paramount. One of the key machines that combines both is the Flexo Printer Slotter Die Cutter (FPSDC). From producing high-quality printed cartons to intricate die-cut designs, this versatile machine has become indispensable for packaging manufacturers. In this guide, we will explore how a flexo printer slotter die cutter works, its components, advantages, applications, and how choosing the right supplier like Giant can elevate your packaging operations.

What is a Flexo Printer Slotter Die Cutter?

A flexo printer slotter die cutter is an integrated machine designed for printing, slotting, and die-cutting corrugated cartons and paperboard packaging. By combining these functions, manufacturers can streamline production, reduce handling errors, and enhance consistency in product quality.

Unlike standalone flexo printers or die-cutters, this hybrid system allows for continuous workflow—printing graphics, creating folds, and cutting custom shapes in a single pass. This not only saves time but also reduces labor costs and the risk of misalignment between different production stages.

Key Components of a Flexo Printer Slotter Die Cutter

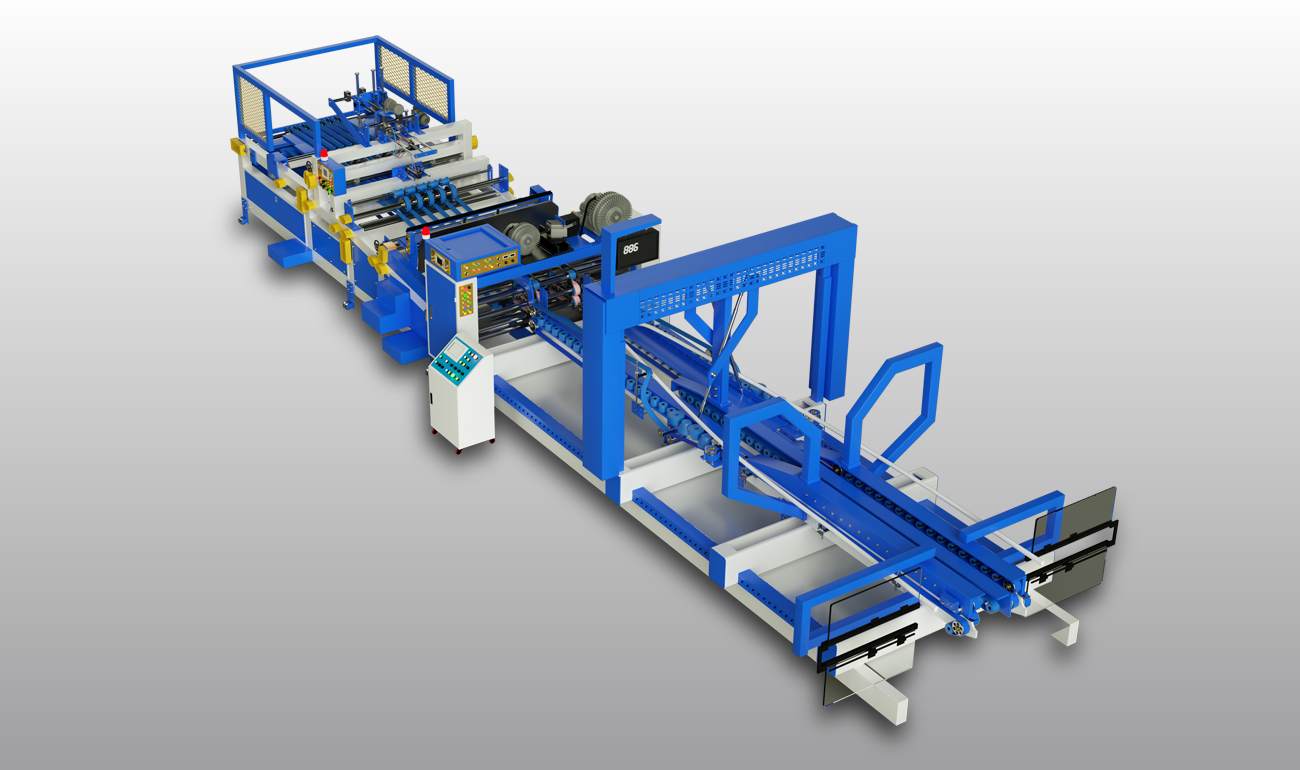

Understanding the main parts of a flexo printer slotter die cutter helps to grasp how the machine works.

Flexo Printing Unit

The first stage is the flexographic printing section, which uses flexible relief plates to transfer ink onto the substrate. Modern machines support multiple colors, allowing for high-resolution graphics and brand logos to be printed on cartons. Some advanced units also feature UV or water-based ink options, ensuring vibrant colors and faster drying times.

Slotting Section

After printing, the cartons pass through the slotting unit, where precise grooves or slots are cut to allow folding. Slotting ensures the final box can be assembled quickly and accurately. Adjustable knives allow operators to handle various board thicknesses and styles.

Die-Cutting Section

The die-cutter creates custom shapes, cutouts, or perforations. Die-cutting is essential for specialty packaging like window boxes, custom inserts, or promotional packaging. This section uses rotary dies for speed and efficiency, maintaining clean cuts even at high production volumes.

Conveyor and Feeding System

A well-designed feeding system ensures smooth transport of materials from printing to slotting and die-cutting. Automated feeding systems minimize material jams and reduce downtime, a crucial factor for manufacturers aiming for maximum productivity.

Control Panel and Automation

Modern machines include digital controls, touch screens, and automation features. Operators can program print registration, slotting positions, and die-cut patterns, ensuring minimal errors. Some units even integrate remote monitoring for predictive maintenance.

How a Flexo Printer Slotter Die Cutter Works: Step by Step

To understand the process fully, here's a simplified step-by-step workflow:

Material Loading

The operator loads sheets of corrugated board or paperboard onto the feeder. The machine's registration system ensures each sheet aligns precisely for accurate printing and cutting.

Printing Stage

The flexo unit prints brand designs, product information, or other graphics onto the cartons. Multi-color registration ensures the images are sharp and consistent.

Slotting Stage

The printed sheets move into the slotting unit. Knives cut precise slots for folds, ensuring the boxes will assemble perfectly. This stage reduces manual folding errors.

Die-Cutting Stage

The sheets then enter the die-cutting section. Rotary dies punch out the desired shapes. For example, window cutouts for retail boxes or intricate patterns for marketing purposes.

Delivery and Stacking

Completed cartons are automatically delivered to the stacking area, ready for packing or further processing. Automated stacking ensures minimal handling damage and keeps the workflow efficient.

Advantages of Using a Flexo Printer Slotter Die Cutter

Investing in a flexo printer slotter die cutter offers multiple advantages for manufacturers:

Increased Productivity

By combining printing, slotting, and die-cutting in a single machine, production times are significantly reduced. Operators can achieve higher throughput without sacrificing quality.

Consistent Quality

Integrated systems reduce errors caused by manual handling between machines. The result is uniform print quality, precise slots, and clean die cuts every time.

Cost Efficiency

Fewer machines mean lower maintenance costs, reduced labor, and less energy consumption. Plus, minimizing material waste improves profitability.

Versatility

Flexo printer slotter die cutters can handle different board thicknesses, sizes, and designs. Whether it's standard shipping boxes or premium retail packaging, these machines can adapt easily.

Reduced Waste

Accurate cutting and slotting minimize scrap material. Some machines even include scrap collection systems for easier recycling.

Applications of Flexo Printer Slotter Die Cutter

The applications are vast, and this machine is ideal for any industry requiring printed cartons or specialty packaging:

- E-commerce Packaging: Custom branded boxes for online retailers.

- Food & Beverage: Folding cartons for juice, snacks, or frozen products.

- Consumer Electronics: Durable packaging with protective inserts.

- Retail & Promotional: Window boxes, gift boxes, or limited-edition packaging.

Choosing the Right Supplier: Why Giant Stands Out

When investing in high-end packaging machinery, choosing the right supplier is crucial. Giant has established itself as a trusted manufacturer of flexo printer slotter die cutters. Here's why:

- Reliable Performance: Giant machines are built for high-speed, high-volume production without compromising quality.

- Advanced Technology: From multi-color printing units to automated die-cutting systems, Giant integrates the latest innovations.

- Customization Options: Whether you need special slotting configurations, additional die stations, or larger sheet sizes, Giant provides tailored solutions.

- After-Sales Support: Giant offers training, spare parts, and maintenance, ensuring your production line stays efficient.

By choosing Giant, manufacturers can maximize output, minimize downtime, and stay ahead in the competitive packaging market.

Maintenance Tips for Longevity

Even the most advanced machines require regular maintenance. Here are some best practices:

- Daily Cleaning: Remove dust, ink residue, and paper scraps.

- Lubrication: Keep moving parts lubricated to reduce wear.

- Check Registration: Regularly verify print and slotting alignment.

- Replace Worn Dies and Knives: Sharp tools ensure clean cuts and reduce material waste.

- Software Updates: Keep control systems updated for optimal performance.

Proper maintenance ensures your flexo printer slotter die cutter delivers consistent results for years.

Future Trends in Flexo Printing and Die Cutting

The packaging industry is evolving rapidly. Key trends include:

- Smart Automation: Integration with IoT for real-time monitoring and predictive maintenance.

- Eco-Friendly Inks: Shift towards water-based and UV-curable inks for sustainability.

- Digital Flexo Hybrid Systems: Combining digital printing with flexo for high-quality short runs.

- Customizable Packaging: Consumer demand for unique and interactive packaging designs continues to grow.

Manufacturers adopting these trends can stay competitive and increase market share.

Conclusion

A flexo printer slotter die cutter is more than just a machine—it's a complete packaging solution. By integrating printing, slotting, and die-cutting into a single workflow, manufacturers achieve higher productivity, consistent quality, and lower production costs. With reliable partners like Giant, businesses can unlock the full potential of their packaging operations and meet growing market demands.

Whether you're producing standard cartons, intricate die-cut designs, or high-quality retail packaging, understanding how a flexo printer slotter die cutter works is key to making informed investment decisions in 2025.

FAQ

Q1: What materials can a flexo printer slotter die cutter handle?

A: Most machines handle single-wall, double-wall, and triple-wall corrugated boards, as well as paperboard and specialty packaging materials.

Q2: Can the machine print multiple colors?

A: Yes, modern units support multi-color flexo printing, including UV and water-based inks for vibrant, durable results.

Q3: What is the production speed of a typical machine?

A: Depending on the configuration, speeds can reach up to 10,000 sheets per hour for standard corrugated boxes.

Q4: Does Giant provide customization?

A: Absolutely. Giant offers custom slotting, die-cutting configurations, and optional automation packages tailored to your needs.

Q5: How do I maintain the machine for optimal performance?

A: Regular cleaning, lubrication, knife replacement, and software updates are essential for consistent output.