Top 10 Features to Look for in a Modern Flexo Printing Machine

Flexographic printing has become a cornerstone of modern packaging, from corrugated cartons to pizza boxes, retail boxes, and food-grade packaging. Selecting the right flexo printing machine is crucial for maintaining high-quality prints, improving production efficiency, and reducing operational costs.

For packaging manufacturers, understanding the top features of a modern flexo printing machine can guide them toward a smart investment. Whether you operate a small workshop or a large industrial facility, the right machine can dramatically improve productivity and brand impact.

As a professional flexographic printing machine and corrugated box making equipment supplier, Giant has extensive experience helping clients achieve high-quality, efficient, and cost-effective printing solutions for a wide range of packaging applications.

1. High-Speed Printing Capability

Speed is one of the primary advantages of modern flexo printing machines. High-speed printing allows manufacturers to meet large orders efficiently, such as pizza box printing for restaurant chains or branded e-commerce packaging.

Modern machines can produce thousands of impressions per hour without compromising print quality. Combined with automation features like automatic plate changes, high-speed flexo printers save both time and labor costs.

Giant's high-speed flexo printing machines are engineered for reliability, enabling manufacturers to handle both small and large production runs with consistent results.

2. Multi-Color Printing for Vibrant Designs

Modern packaging often requires vibrant, multi-color graphics. Look for a flexo printing machine capable of:

- Two-color to six-color printing

- Spot colors for brand consistency

- CMYK process printing for detailed graphics

These features are essential for pizza boxes, retail cartons, and premium corrugated packaging. Multi-color capabilities allow brands to stand out on crowded shelves, ensuring every package delivers a strong visual impact.

Giant flexo printers offer precise color registration, ensuring colors remain consistent across high-volume runs.

3. Precision Registration and Alignment

Accurate registration is critical in multi-color printing. Misaligned colors can result in blurred images, wasted materials, and additional costs. Modern flexo presses include:

- Automatic registration systems

- Fine manual and digital adjustments

- Real-time monitoring for alignment errors

These features ensure that every print, whether a pizza box or shipping carton, meets brand standards. Giant's flexo machines use advanced alignment technology to reduce waste and improve overall production efficiency.

4. Wide Substrate Compatibility

A versatile flexo printing machine should handle various materials, including:

- Corrugated cardboard

- Kraft paper

- Coated boards

- Food-safe packaging materials

This allows manufacturers to produce different types of packaging with a single machine, reducing the need for multiple presses and optimizing factory space. Flexo printing machines can also adjust to different thicknesses and textures, ensuring sharp prints on every substrate.

5. Efficient Ink and Drying Systems

Ink efficiency and proper drying are vital for high-quality results. Modern machines feature:

- Water-based inks suitable for food packaging

- UV curing options for faster drying and vibrant colors

- Infrared or hot-air drying systems to speed up production

Efficient ink systems minimize waste, lower operational costs, and reduce environmental impact. Giant flexo printers integrate these systems seamlessly, supporting sustainable production while maintaining excellent print quality.

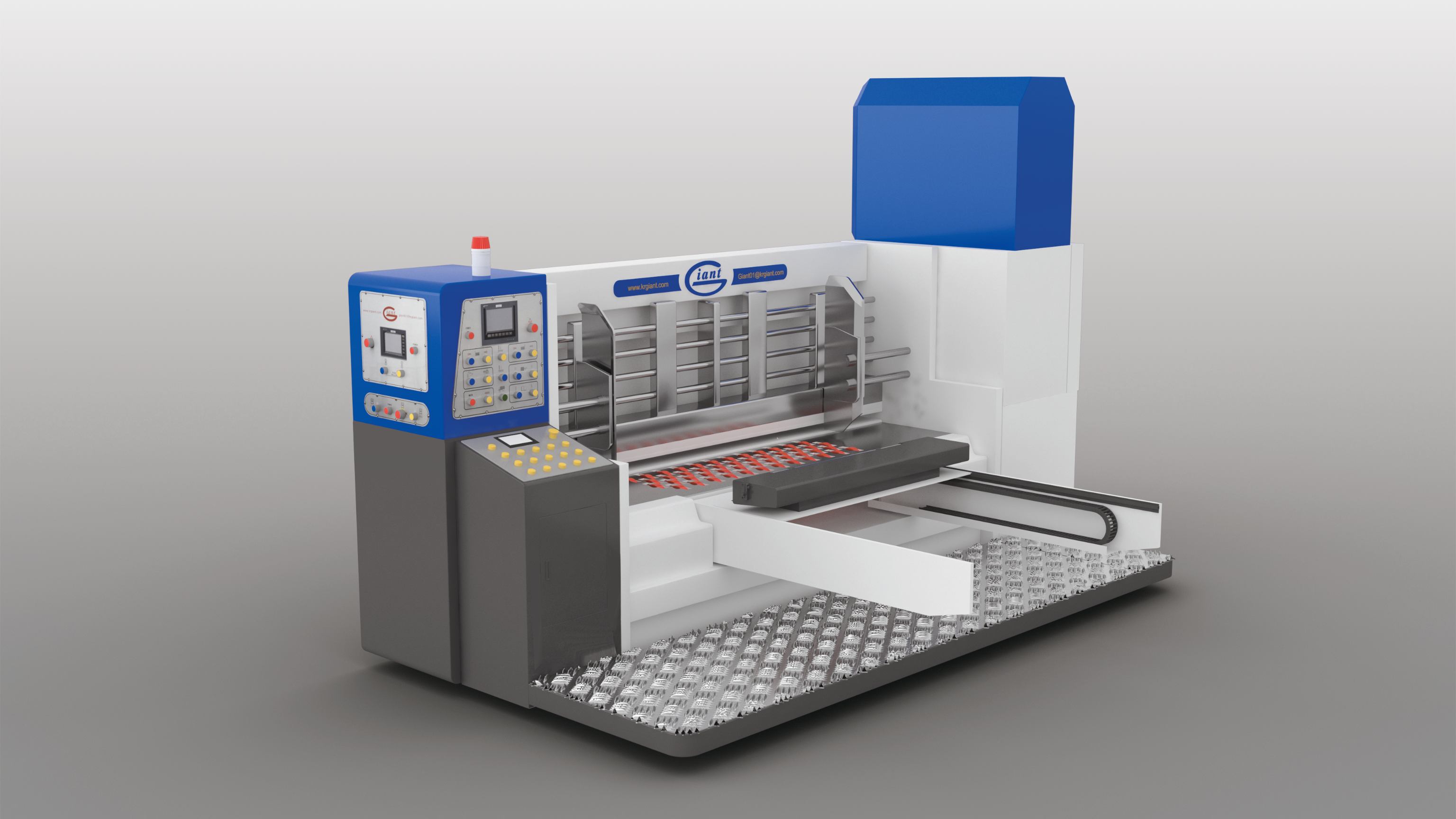

6. User-Friendly Control Panels

Ease of operation is crucial to minimize downtime and operator errors. Look for machines with:

- Touchscreen interfaces

- Pre-set printing profiles for repeat jobs

- Intuitive controls for ink flow, speed, and pressure

These features allow operators to run complex print jobs efficiently, even with minimal experience. Giant's flexo printing machines prioritize usability, ensuring that your team can operate the machine safely and effectively.

7. Automation Features

Automation reduces setup times and increases production consistency. Key features include:

- Automatic plate changes

- Ink viscosity and flow control

- Job memory for recurring orders

By automating these processes, manufacturers can reduce human error, improve output quality, and increase overall productivity. Giant's modern flexo presses incorporate intelligent automation tailored for various packaging applications, including pizza boxes and corrugated cartons.

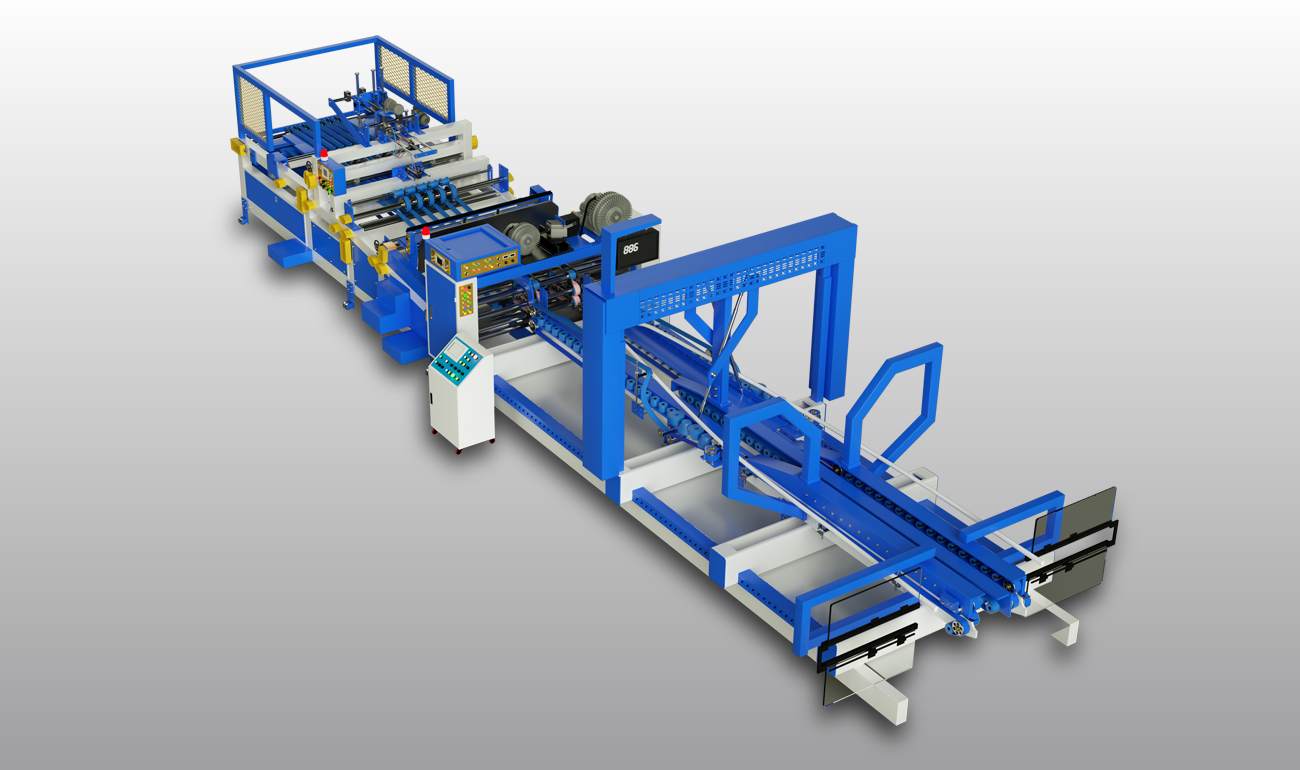

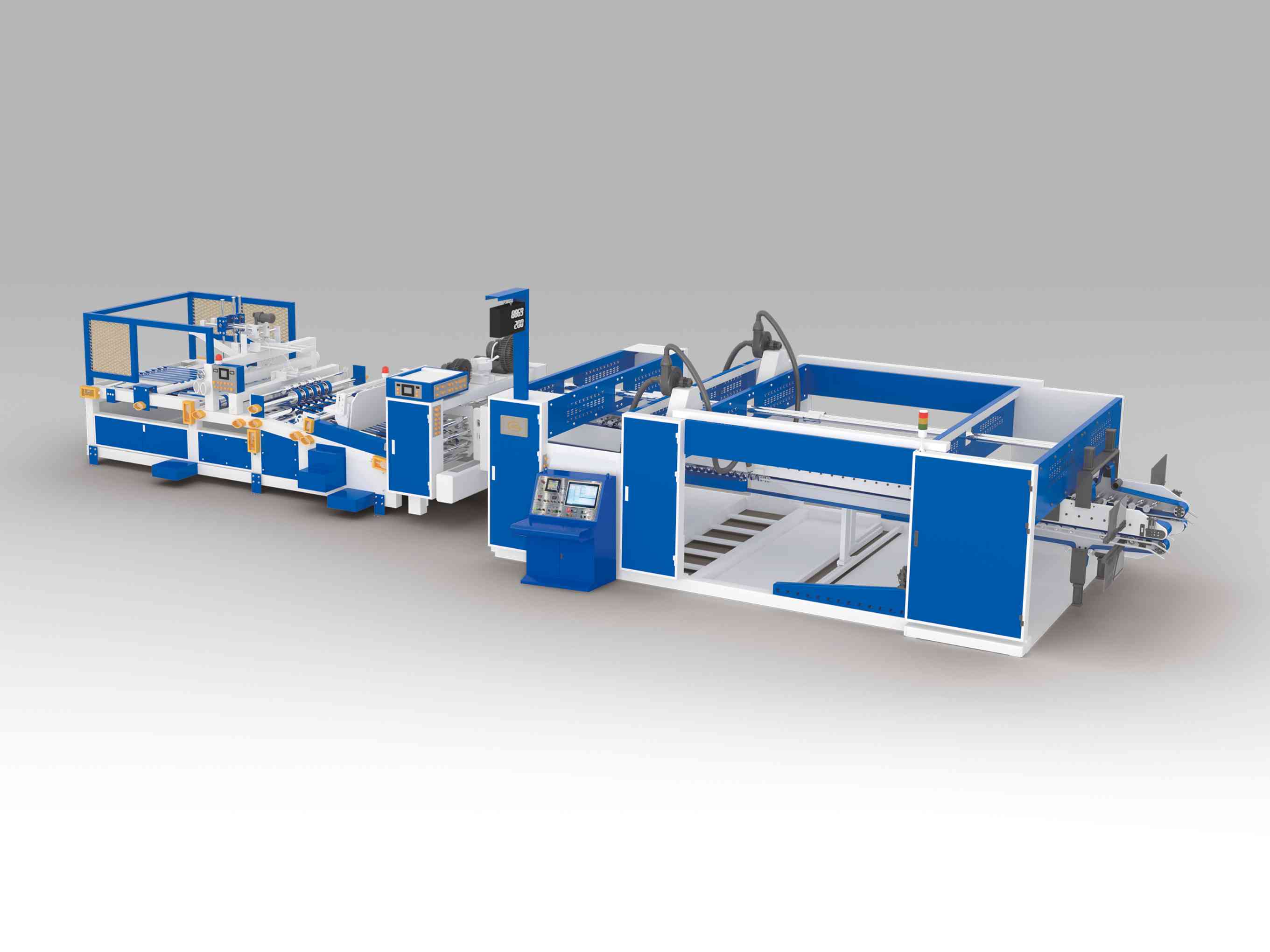

8. Integration with Corrugated Box Production Lines

Many manufacturers integrate their flexo printing machines with corrugated box making equipment, allowing printing, slotting, folding, and gluing in a single production line. This integration:

- Reduces labor costs

- Speeds up production

- Minimizes handling errors

Giant provides complete solutions that combine flexo printing and corrugated box forming machines, ensuring seamless workflows from start to finish.

9. Maintenance and Durability

Long-term reliability and low maintenance are key considerations. Modern machines should have:

- Easy-to-clean ink systems

- Quick-change plates and rollers

- Robust mechanical structures designed for continuous operation

With durable machines like Giant flexo printers, manufacturers can minimize downtime, reduce maintenance costs, and ensure consistent production output for years.

10. Safety and Compliance

Safety and compliance are essential, particularly when printing food packaging. Features to look for:

- Food-safe ink compatibility

- Emergency stop mechanisms

- Safety guards and shields

- Eco-friendly printing options with low VOC emissions

Ensuring safety protects employees and maintains regulatory compliance, especially for packaging in the food industry. Giant's flexo machines meet industry standards for both safety and environmental performance.

Conclusion

Selecting a modern flexographic printing machine requires careful consideration of multiple factors, including speed, color capability, registration accuracy, substrate versatility, ink efficiency, automation, and integration with production lines.

For manufacturers producing pizza boxes, corrugated cartons, or retail packaging, these ten features are essential for achieving high-quality results, cost efficiency, and brand consistency.

As a trusted supplier, Giant offers a wide range of flexo printing machines and corrugated box making equipment tailored to diverse packaging needs. With advanced technology, durable construction, and user-friendly operation, Giant machines help manufacturers produce professional, eye-catching packaging while reducing operational costs.