Flexographic Printing vs Offset Printing: Which Is Better for Carton Packaging?

In the competitive packaging market, choosing the right printing technology is critical for product quality, efficiency, and brand impact. For carton packaging, flexographic printing has emerged as the most practical and cost-effective solution. While offset printing is often mentioned in comparisons, companies focusing on corrugated cartons and high-volume production consistently choose flexo printing. This guide explains why flexographic printing is the preferred choice and how partnering with a reliable supplier like Giant can optimize your packaging operations.

What is Flexographic Printing?

Flexographic printing, commonly known as flexo printing, uses flexible relief plates to transfer ink onto a variety of substrates, including corrugated boards, paperboard, and plastic films. It is particularly valued in the packaging industry for its speed, versatility, and ability to print on uneven surfaces, making it ideal for carton packaging.

Key Advantages of Flexo Printing:

- High-speed production for large-volume runs, ideal for e-commerce and logistics packaging.

- Excellent compatibility with coated, uncoated, and corrugated materials.

- Durable inks that resist smudging and fading during shipping and handling.

- Cost-effective setup compared to other printing methods, allowing lower per-unit costs for long runs.

Flexo printing ensures consistent, high-quality results, especially for bold designs, brand logos, and functional carton printing.

Comparing Flexo Printing with Offset Printing

While offset printing is often praised for high-resolution graphics, it is generally less suitable for corrugated cartons due to its reliance on smooth, flat surfaces. Flexo printing, by contrast, is optimized for corrugated and thick substrates, where flexibility, speed, and durability matter most.

In terms of production efficiency, flexo printing outperforms offset printing for high-volume carton runs. Its lower setup costs, faster printing speeds, and minimal material waste make it the go-to choice for manufacturers who need reliable and consistent output.

When considering cost-effectiveness, flexo printing clearly wins for long-run production. Offset may offer higher image resolution for small runs or premium retail boxes, but for corrugated cartons—used in shipping, storage, and retail—flexo printing provides the best balance of speed, quality, and ROI.

Why Flexo Printing Excels in Carton Packaging

Flexo printing is specifically designed to meet the demands of modern carton packaging:

High Production Speed – Flexo machines can print thousands of cartons per hour, supporting mass production without sacrificing quality.

Material Versatility – Whether coated, uncoated, or corrugated, flexo printing adapts to different substrates without extra cost or complexity.

Durable and Functional Prints – Flexo inks ensure your cartons maintain their appearance and legibility through handling, storage, and transport.

Cost Efficiency – Lower plate costs and faster setup save both time and money, particularly for high-volume carton production.

Applications of Flexographic Printing

Flexo printing is widely used across industries, including:

- E-commerce Packaging – Branded cartons for online retailers, optimized for shipping durability.

- Food and Beverage Packaging – Corrugated boxes and paperboard cartons that meet regulatory and branding requirements.

- Consumer Electronics – Sturdy packaging with bold logos and easy-to-read instructions.

- Retail and Promotional Packaging – Flexible printing for custom inserts, bold patterns, and brand-focused designs.

Flexo printing's versatility ensures consistent quality across diverse packaging applications, making it the first choice for many manufacturers.

Choosing Giant for Your Flexo Printing Needs

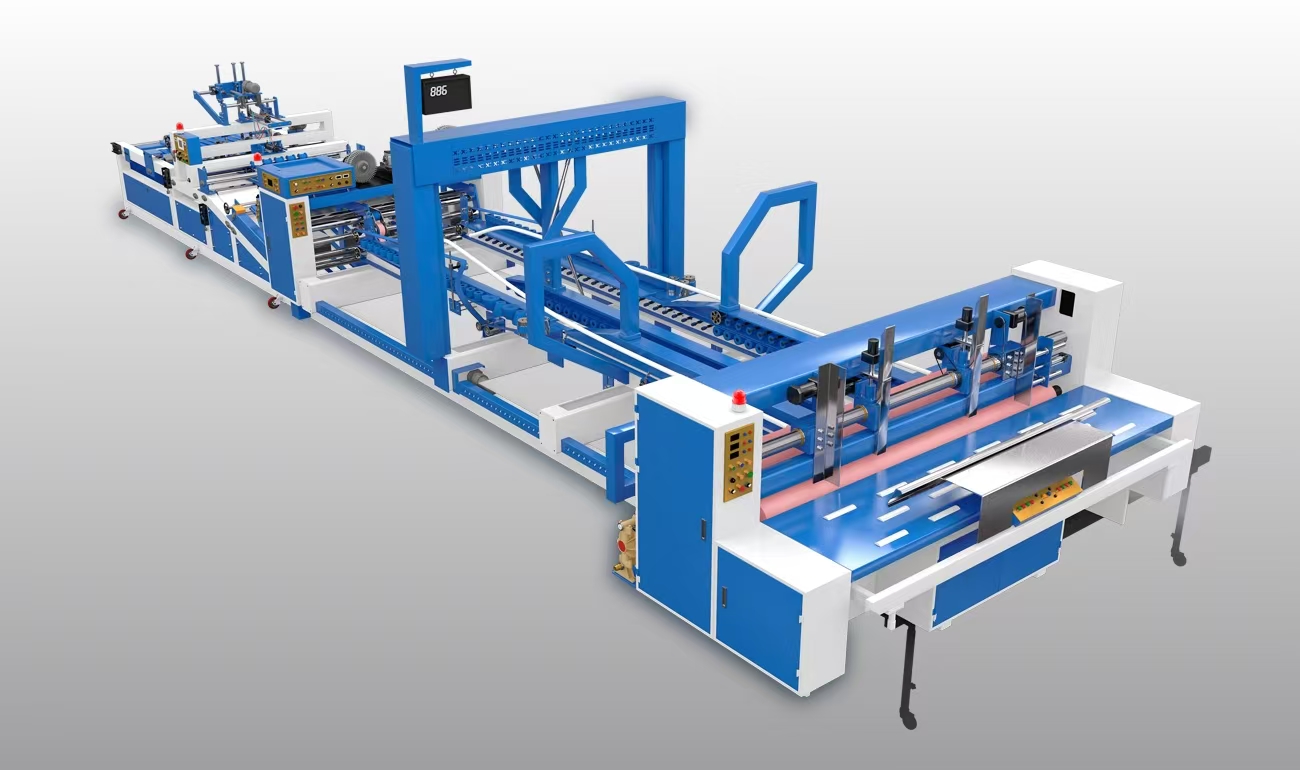

Investing in a reliable flexo printer is critical for maximizing production efficiency and print quality. Giant specializes in advanced flexographic printing machines designed for carton packaging.

Why Choose Giant:

- High-Speed, High-Quality Machines – Capable of printing thousands of cartons per hour with consistent color and sharp graphics.

- Tailored Solutions – Giant machines can be customized for specific substrate types, sheet sizes, and production volumes.

- Durable and Reliable Equipment – Built for long-term production with minimal downtime.

- Comprehensive Support – Training, maintenance, and spare parts ensure your operation runs smoothly and efficiently.

Partnering with Giant allows manufacturers to maximize output, minimize errors, and produce professional-quality cartons consistently.

Key Takeaways

- Flexographic printing is the most efficient and cost-effective choice for corrugated carton packaging.

- Offset printing may provide higher resolution but is less suitable for corrugated or high-volume production.

- Flexo printing ensures durable, high-quality prints with minimal setup costs and waste.

- Choosing a trusted supplier like Giant guarantees advanced machines, tailored solutions, and reliable support.

Conclusion

For manufacturers focused on corrugated carton production, flexographic printing is the clear winner. Its combination of speed, versatility, durability, and cost efficiency makes it ideal for both high-volume shipping cartons and retail-ready packaging. With Giant's advanced flexo printing solutions, businesses can elevate their packaging quality, streamline production, and enhance brand presentation in 2025 and beyond.

FAQ

Q1: Can flexo printing handle detailed graphics?

A: Flexo printing excels at bold designs and logos. While it may not match offset for ultra-fine detail, modern flexo machines provide excellent print clarity for cartons.

Q2: Is flexo printing cost-effective for large runs?

A: Yes, flexo printing has lower setup costs and faster production speeds, making it ideal for high-volume carton production.

Q3: Can flexo printing work on coated and uncoated corrugated boards?

A: Absolutely. Flexo printing is highly versatile and can handle a wide variety of substrates.

Q4: Why choose Giant for flexo printing?

A: Giant offers advanced, high-speed machines with customization options, durable build quality, and full technical support.

Q5: Can flexo printing be combined with other finishing options?

A: Yes, Giant's flexo systems can integrate slotting, die-cutting, and coating for complete packaging solutions.