Why Flexographic Printing Machines Are Ideal for Pizza Box Production

The pizza box is more than just a container—it's a powerful branding tool and a key component of food safety. From bold logos to vibrant colors, high-quality printing plays a vital role in making a pizza brand stand out. For packaging manufacturers, choosing the right printing technology is crucial to achieving consistent results while keeping production costs under control.

Among all printing technologies, flexographic printing machines—often referred to as flexo printers—have become the top choice for producing pizza boxes. Their speed, versatility, and cost-effectiveness make them perfectly suited to the needs of both small pizzerias and large-scale packaging factories.

As a professional supplier of flexographic printing machines and corrugated box making equipment, Giant has extensive experience helping packaging manufacturers achieve high-quality pizza box printing. In this article, we'll explore why flexo technology is ideal for pizza box production and what makes it the best investment for your packaging business.

Superior Printing on Corrugated and Kraft Materials

Pizza boxes are typically made from corrugated cardboard or kraft paperboard—materials known for their durability and eco-friendliness. However, these substrates can be challenging to print on due to their textured surfaces.

Flexographic printing machines excel in this area because they use flexible relief plates and specialized inks that adhere well to rough surfaces. This ensures:

- Sharp, clear logos and text

- Consistent ink coverage

- Minimal smudging or bleeding

At Giant, our corrugated box flexo printers are designed to maintain high print quality even on recycled or rough paper surfaces, ensuring your pizza boxes always look professional.

High-Speed Production for Large Orders

Pizza box production often involves large batch orders, especially for major restaurant chains and delivery services. Flexo printers are capable of extremely high printing speeds, allowing manufacturers to produce thousands of boxes per hour.

With modern automation features—such as automatic plate change and precise ink control—flexographic machines minimize downtime, allowing faster job changes between different pizza box designs.

Giant's high-speed flexo printing machines are engineered to handle both long production runs and quick turnaround orders, making them ideal for the fast-paced food packaging industry.

Cost-Effective Printing for Large Runs

One of the biggest advantages of flexographic printing is its low cost per unit for high-volume production. Once the printing plates are made, they can be reused for tens of thousands of impressions without losing quality. This reduces the cost per pizza box, making it more profitable for manufacturers.

Compared to digital printing, which is better for small custom runs, flexo printing remains the most economical solution for bulk pizza box manufacturing.

Eco-Friendly Printing for Food Packaging

Today's consumers are increasingly concerned about sustainability. Many pizzerias prefer packaging that is eco-friendly, recyclable, and safe for direct contact with food.

Flexographic printing supports this trend by:

- Using water-based inks that are food-safe and low in VOC emissions

- Printing directly on biodegradable corrugated cardboard

- Reducing waste through efficient ink usage

Giant's flexo printers are compatible with eco-friendly ink systems, helping manufacturers meet food safety regulations and environmental standards without compromising print quality.

Versatility for Different Pizza Box Designs

Pizza boxes come in many shapes and sizes—from small personal pizza boxes to large family-sized cartons. Flexographic printing machines are highly adaptable, allowing operators to adjust printing widths and plate sizes to fit different box formats.

With multi-color printing capabilities, flexo machines can produce:

- Two-color designs for basic branding

- Four-color process prints for more vibrant, detailed graphics

- Special spot colors for brand consistency

At Giant, we offer flexo printing machines in multiple configurations, giving packaging manufacturers the flexibility to handle different client requirements with ease.

Consistent Branding Across All Orders

Brand consistency is crucial in the food industry. Customers recognize a pizza brand by its colors, logo, and box design. Flexographic printing delivers uniform results across thousands of boxes, ensuring that every package reflects the same professional image.

This consistency also supports franchise operations, where every location needs identical packaging to maintain a cohesive brand identity.

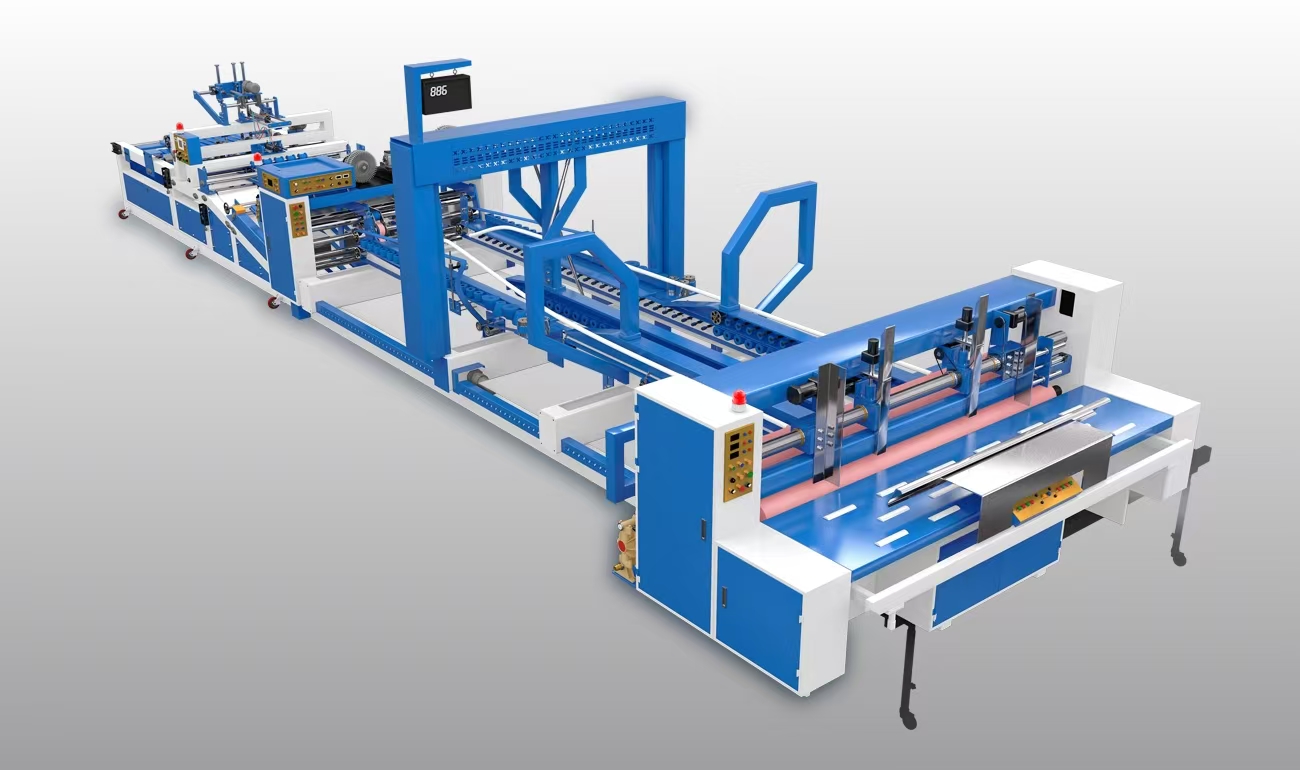

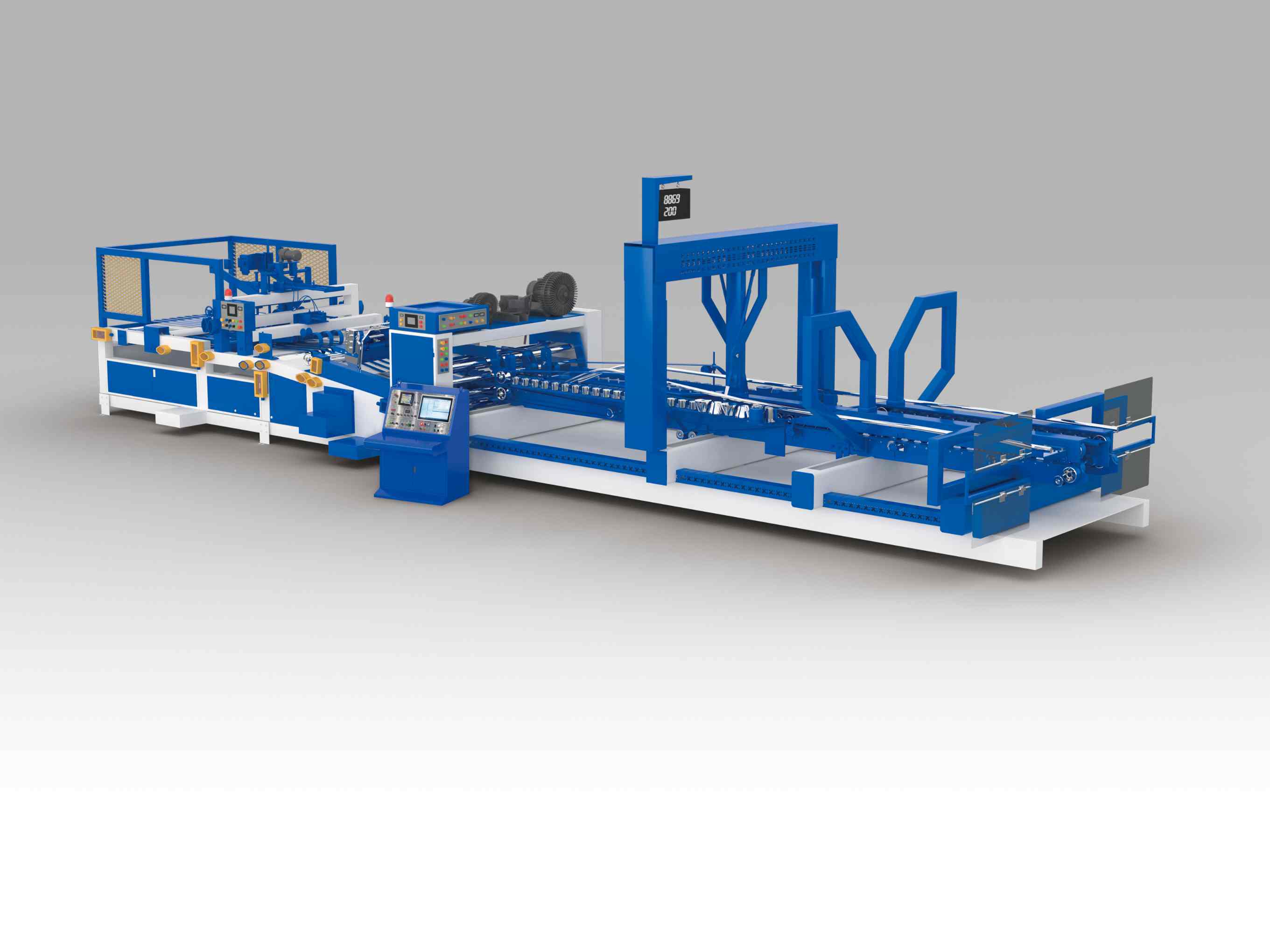

Integration with Corrugated Box Making Lines

For maximum efficiency, many manufacturers integrate their flexographic printing machines with corrugated box making machines. This allows the process of printing, slotting, folding, and gluing to happen in a single production line.

Giant specializes in providing complete solutions, including corrugated box flexo printers and box forming machines, to help customers streamline production and reduce labor costs.

Reliable Performance and Easy Maintenance

Downtime can be expensive in high-volume pizza box production. Modern flexographic machines are designed for durability and ease of maintenance. Features such as quick-change printing plates, easy-to-clean ink systems, and automated alignment help reduce setup times and keep production running smoothly.

Giant's machines are built with robust materials and advanced engineering to ensure long-term reliability, even under continuous operation.

Meeting the Needs of Both Small and Large Producers

Whether you are a small printing shop producing pizza boxes for local restaurants or a large-scale manufacturer supplying national pizza chains, flexographic printing machines can be tailored to your needs:

- Small-scale operators benefit from compact, cost-effective machines with lower print widths.

- Large-scale factories prefer fully automated, high-speed systems for mass production.

Giant offers custom services to fit different production capacities, ensuring every business can find the right solution.

Conclusion

Flexographic printing machines are the perfect match for pizza box production thanks to their speed, cost efficiency, eco-friendliness, and ability to produce consistent, high-quality prints on corrugated cardboard. For manufacturers, this technology offers a reliable way to meet customer demands while keeping production costs low.

With years of experience in the packaging machinery industry, Giant provides high-performance flexographic printing machines and corrugated box production solutions that are tailored to the specific needs of pizza box manufacturers. Our machines combine precision engineering with user-friendly design, helping our clients deliver packaging that looks great, performs well, and supports their brand image.

If you're looking to upgrade your pizza box production line or invest in a new flexo printing solution, Giant can help you choose the perfect machine for your business.