Corrugated Carton Manufacturing: Why Flexo Printing Machines Are the Best Choice

Corrugated cartons have become an essential part of modern packaging, widely used for shipping, food delivery, and retail. Their durability, lightweight structure, and ability to protect products during transport make them the preferred choice for industries ranging from e-commerce to food and beverages. As global demand for corrugated cartons continues to grow, manufacturers face increasing pressure to deliver high-quality packaging at faster speeds and lower costs.

To meet these demands, many companies are turning to flexographic printing machines. Flexo technology has established itself as the most effective solution for corrugated carton printing because it combines speed, quality, and cost efficiency. In this article, we will explore in detail why flexographic printing machines are considered the best choice for corrugated carton manufacturing and how Giant, a trusted supplier of flexographic printing machines and corrugated bottom machines, helps businesses achieve higher performance.

Understanding Flexographic Printing Technology

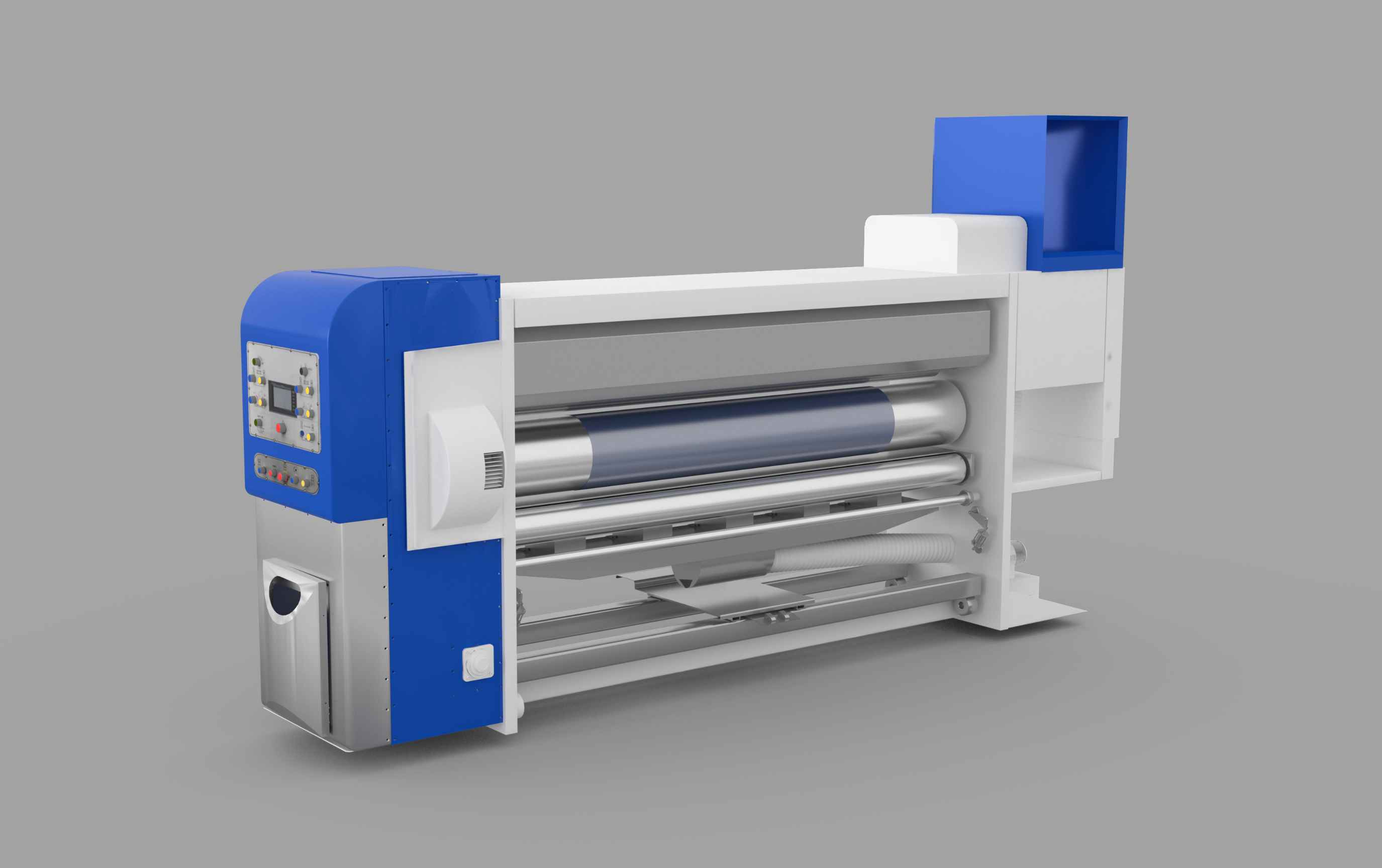

Flexographic printing, often called flexo printing, is a direct printing method that uses flexible relief plates made of rubber or photopolymer. These plates are wrapped around rotating cylinders, which apply quick-drying inks onto the substrate. Unlike offset printing or digital printing, flexo technology is optimized for continuous high-volume production, which makes it particularly suitable for packaging applications.

Key characteristics of flexo printing include:

- Versatility of substrates: corrugated board, kraft paper, films, foils, and more.

- Fast-drying inks: allows immediate stacking, folding, or die-cutting after printing.

- Adaptability: supports both simple one-color prints and complex multi-color graphics.

- High efficiency: ideal for long runs where consistency and speed are critical.

Why Flexographic Printing Machines Dominate Corrugated Carton Manufacturing

1. Optimized for Corrugated Board

Corrugated boards often have uneven or porous surfaces that are not suitable for offset printing. Flexographic printing machines are designed to handle these materials effectively. With precise plate technology and advanced anilox rollers, flexo systems can deliver sharp logos, clear barcodes, and detailed graphics, even on recycled or low-grade corrugated sheets.

2. Cost-Effective Production

For carton manufacturers, cost efficiency is a major factor. Flexographic printing machines offer low-cost plates that can be reused for millions of impressions, reducing setup costs. Compared to digital printing, flexo becomes more economical for bulk orders, such as pizza boxes, shipping cartons, or beverage packaging.

3. High-Speed Output

Modern flexographic presses can run at extremely high speeds, sometimes exceeding 600 meters per minute. This allows packaging companies to produce thousands of cartons per hour while maintaining consistent print quality. For businesses with tight delivery schedules, such as fast-food packaging suppliers or e-commerce vendors, this speed is a decisive advantage.

4. Wide Range of Ink Options

Flexo printing supports water-based, solvent-based, and UV-curable inks. This flexibility ensures that manufacturers can choose inks according to specific needs:

- Water-based inks: eco-friendly, suitable for food-grade packaging.

- Solvent-based inks: high durability for cartons exposed to moisture or oil.

- UV inks: vibrant colors and quick curing for premium packaging.

5. Sustainability Benefits

Sustainability has become a driving factor in packaging. Flexographic printing machines are compatible with biodegradable inks and recyclable corrugated substrates, enabling manufacturers to reduce their environmental footprint. With more consumers and brands demanding eco-friendly packaging, this advantage cannot be overlooked.

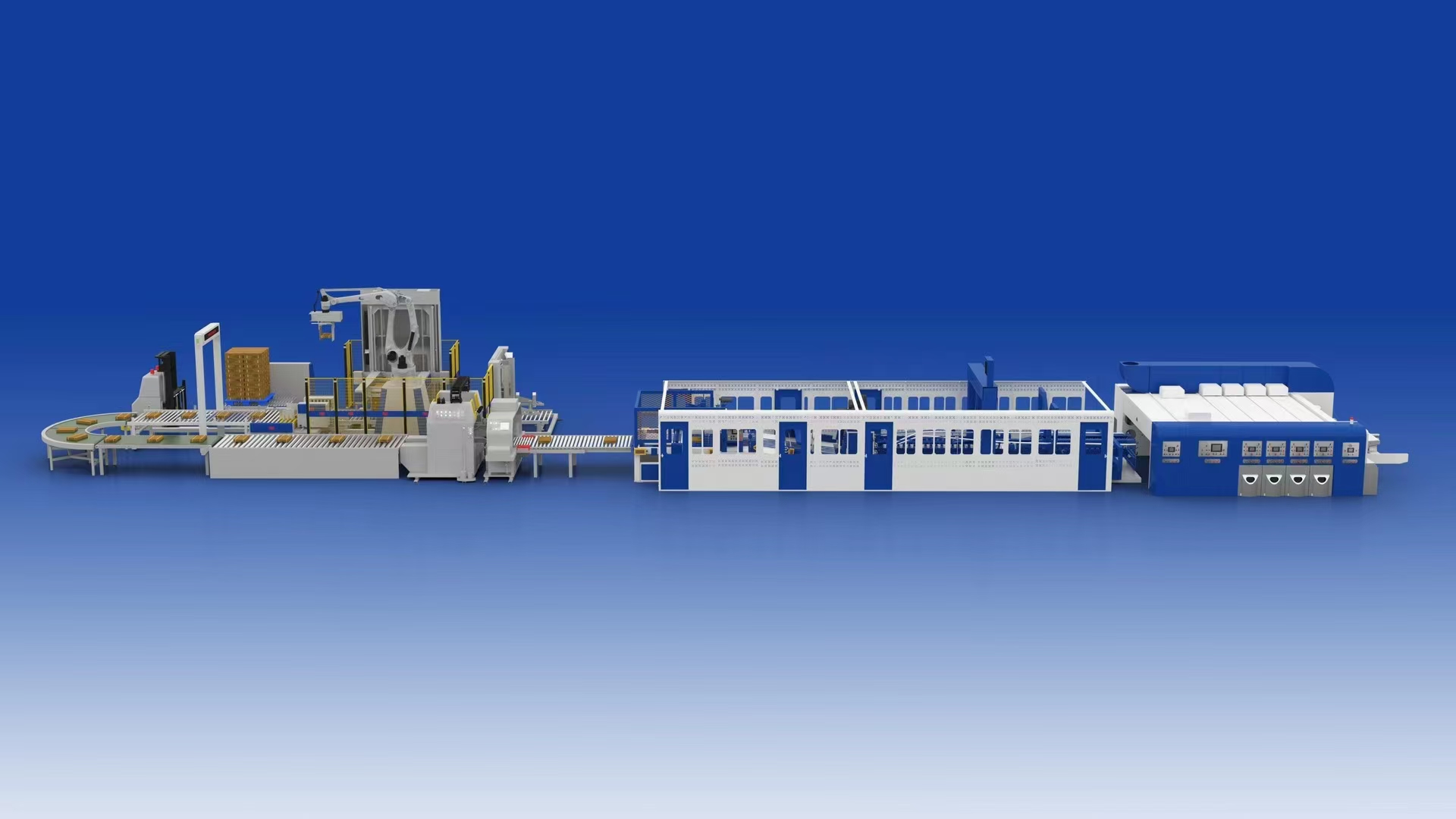

6. Easy Integration with Other Processes

Corrugated carton manufacturing often requires multiple steps such as cutting, folding, and gluing. Flexographic machines can be easily integrated with die-cutting systems and folder-gluers, streamlining the entire production line. This reduces downtime, improves workflow efficiency, and lowers labor costs.

Practical Applications of Flexo Printing in Carton Manufacturing

Pizza Boxes

Flexographic machines produce high-quality prints with food-safe inks, ensuring pizza boxes are both attractive and safe for direct food contact.

E-Commerce Shipping Boxes

With the growth of online retail, corrugated cartons for shipping require durable branding and custom graphics. Flexo printing enables customized logos, QR codes, and handling instructions directly on the boxes.

Retail and Consumer Packaging

Flexographic presses allow vibrant, shelf-ready packaging with consistent color accuracy. This is crucial for branding in competitive retail spaces.

Food & Beverage Packaging

From beverage carriers to bakery boxes, flexo printing ensures compliance with safety standards while maintaining appealing designs.

Industry Trends: Why Flexo Printing Is the Future

- Shift to Sustainable Packaging: Brands are moving away from plastic and toward recyclable corrugated cartons. Flexo technology supports this transition.

- Growth in Food Delivery Services: Demand for pizza boxes, takeaway packaging, and food cartons continues to rise, driving the need for efficient carton printing.

- Customization and Short Runs: While digital printing serves ultra-short runs, flexo remains dominant for medium-to-large production with cost advantages.

- Automation and Smart Machines: Modern flexo presses include automatic plate changing, digital controls, and AI-based quality inspection, reducing waste and human error.

Best Practices for Manufacturers Using Flexographic Printing

To maximize the performance of a flexographic printing machine in corrugated carton production, manufacturers should:

Maintain Anilox Rollers – Regular cleaning ensures consistent ink transfer and color accuracy.

Choose the Right Ink – Water-based inks for food packaging, solvent-based for durable outdoor cartons.

Optimize Plate Design – High-quality photopolymer plates reduce wear and improve print sharpness.

Invest in Operator Training – Skilled operators can reduce downtime and extend machine lifespan.

Implement Preventive Maintenance – Routine checks on bearings, gears, and rollers prevent unexpected breakdowns.

Why Partner with Giant?

At Giant, we provide cutting-edge flexographic printing machines and corrugated bottom machines specifically designed for the packaging industry. Our machines are engineered for:

- High-speed production with consistent print quality.

- Energy efficiency and eco-friendly printing for sustainable operations.

- Long-term durability with user-friendly controls and automation features.

By choosing Giant, packaging manufacturers gain a partner dedicated to helping them reduce costs, increase productivity, and stay competitive in a fast-growing market.

Conclusion

Corrugated carton manufacturing is at the heart of modern packaging, and the choice of printing technology directly impacts efficiency, cost, and quality. Flexographic printing machines stand out as the best choice because they are optimized for corrugated substrates, deliver superior print results, and support sustainable practices.

For carton manufacturers producing pizza boxes, retail packaging, or e-commerce cartons, investing in flexo technology ensures both short-term productivity gains and long-term business growth.

With decades of expertise, Giant continues to provide reliable flexographic printing solutions that empower packaging companies worldwide. By adopting flexographic printing, manufacturers not only meet today’s packaging challenges but also prepare for the future of sustainable, high-quality carton production.

FAQ

Q1: Is Flexographic Printing Better than Digital Printing for Corrugated Cartons?

Yes. Flexo printing is more cost-effective for large production runs and works better on rough corrugated surfaces compared to digital printing.

Q2: Can Flexo Printing Machines Use Eco-Friendly Inks?

Absolutely. Flexo machines support water-based and biodegradable inks, making them suitable for sustainable packaging solutions.

Q3: Why Should Carton Manufacturers Choose Giant’s Flexographic Machines?

Giant offers advanced, durable, and efficient flexo printing machines that combine high performance with eco-friendly features, helping manufacturers cut costs while maintaining quality.