Guardians of Print Quality: Daily and Deep Cleaning for Ceramic Anilox Rollers

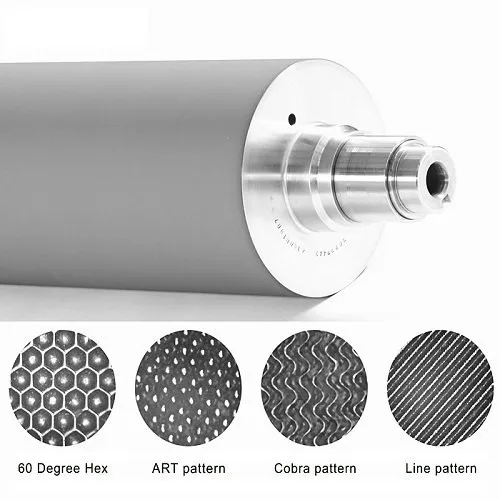

For print professionals, particularly in the corrugated packaging industry, the ceramic anilox roller is the linchpin of precise ink transfer and consistent print quality. Its microscopic cells are designed to accurately meter and deliver ink, directly influencing color vibrancy, image crispness, and production efficiency. To ensure optimal performance and extend the lifespan of these critical components, understanding and implementing proper cleaning and maintenance protocols are paramount. Neglecting anilox care can lead to clogged cells, reduced ink transfer volume, inconsistent print results, and increased costs.

The Dual Approach: Daily vs. Periodic Cleaning

It's crucial to differentiate between daily and periodic (deep) cleaning procedures for ceramic anilox rollers, as each serves a distinct purpose

Daily Cleaning (Preventative Maintenance):

- Immediacy is Key: The most critical rule for ceramic anilox roller maintenance is to clean the roller immediately after each print job, before the ink has a chance to dry in the cells. Dried ink is significantly harder to remove and can lead to persistent clogging.

- Recommended Tools: For routine anilox cleaning, use a stainless steel brush along with an anilox cleaning gel specifically recommended by your anilox or ink supplier. The goal of any cleaning procedure is to penetrate to the bottom of the microscopic cells, ensuring thorough ink removal.

- Methods: Manual cleaning by applying a cleaning agent to the roller surface is a common daily method.

Periodic (Deep) Cleaning (Restorative Maintenance):

- While daily cleaning prevents accumulation, deep anilox cleaning is necessary to remove stubborn, dried ink that daily routines might miss. This restores the roller's original cell volume and ink transfer capabilities.

- Advanced Methods: Various deep cleaning methods exist, including ultrasonic cleaning, laser cleaning, and specialized chemical immersion. The choice depends on the severity of the clogging and the type of ink used. These methods are designed to penetrate deep into the anilox cells.

Essential Tips for Longevity and Performance:

- Reduce Wear and Tear: Proper cleaning practices directly contribute to reducing normal wear and tear on the anilox roller surface.

- Enhance Corrosion Resistance: Using the correct cleaning agents and procedures helps maintain the ceramic coating's corrosion resistance, preventing damage over time.

- Prevent Abrasion: Regular and effective cleaning removes abrasive particles that can accumulate and cause scoring or damage to the anilox surface.

By implementing a rigorous cleaning regimen that includes both daily preventative measures and periodic deep cleaning, print facilities can significantly extend the life of their ceramic anilox rollers, maintain consistent print quality, and ensure efficient, cost-effective production.

What's your go-to method for deep cleaning anilox rollers, and what results have you seen? Share your insights below!

#CeramicAniloxRoller #AniloxCleaning #PrintMaintenance #FlexoPrinting #CorrugatedPackaging #PrintQuality #OperationalExcellence #InkManagement #PrintingTips