Fully Automatic Flexo Printer Slotter Die Cutter: Key Benefits and Why Manufacturers Prefer It

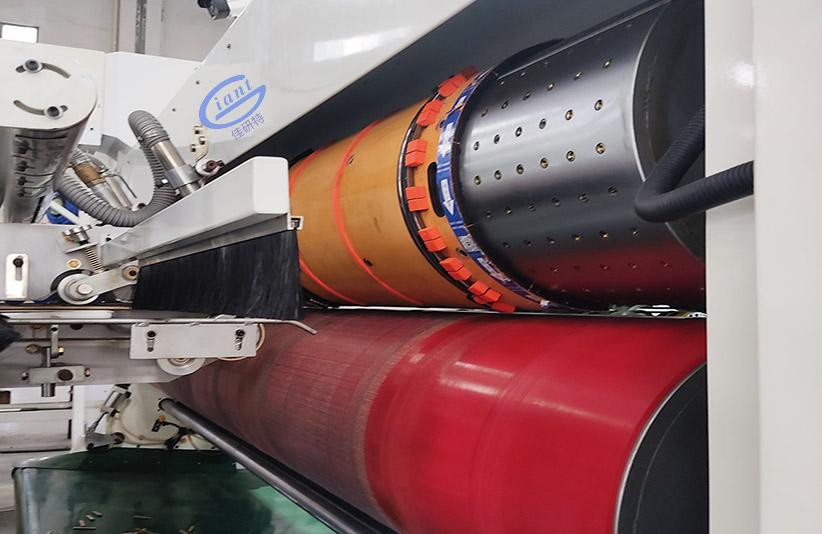

In today's fast-paced packaging industry, speed, precision, and automation have become essential for staying competitive. This is why more factories are upgrading from traditional carton-making machines to a fully automatic flexo printer slotter die cutter—a single integrated system designed to handle printing, slotting, die cutting, creasing, trimming, and stacking with minimal human intervention.

As someone who works closely with packaging manufacturers, I see a clear shift toward higher automation, smarter operation, and enhanced print quality. And among all the solutions we provide at Giant, our fully automatic flexo printer slotter die cutter series has become one of the most in-demand choices for corrugated box production lines.

In this comprehensive guide, I will explain what makes these machines so powerful, why so many manufacturers prefer them, and how they help optimize efficiency, reduce costs, and improve product quality.

What Is a Fully Automatic Flexo Printer Slotter Die Cutter?

A fully automatic flexo printer slotter die cutter is an integrated corrugated box making machine capable of completing multiple processes in one run:

Key Functions

- Flexographic printing

- Automatic slotting and scoring

- Rotary die cutting

- Creasing and trimming

- Inline folding and stacking (optional)

- Automatic feeding and delivery

- Real-time error detection and adjustment

The biggest advantage is full automation, which means minimal manual handling, consistent output quality, and far fewer production errors.

Why Manufacturers Prefer Fully Automatic Flexo Printer Slotter Die Cutters

Below are the core reasons more factories are shifting to these advanced machines.

1. High-Speed Production With Outstanding Efficiency

Speed matters. In the corrugated packaging industry, customers expect faster delivery cycles and higher output volumes. Fully automatic systems outperform traditional equipment with:

Higher running speeds

- Up to 200–350 sheets per minute

- Continuous feeding without pauses

- Faster setup and changeover time

Reduced manual intervention

Because the machine performs printing, slotting, and die-cutting in one line, workers no longer need to transfer sheets between separate machines.

Optimal workflow integration

The system synchronizes all modules—printer, slotter, die cutter, stacker—ensuring each sheet is processed seamlessly.

This level of efficiency allows factories to deliver more orders in less time with fewer operators.

2. Superior Print Quality for Modern Packaging Requirements

Flexo printing has evolved dramatically. The print quality of modern fully automatic flexo printer slotter die cutters can rival some digital machines—at a fraction of the cost.

Color accuracy and sharpness

- High-resolution printing (up to 250–300 LPI)

- Uniform ink distribution

- Stability during long runs with servo-controlled registration

Compatibility with various printing plates

- Water-based environmentally friendly inks

- Quick-change polymer plates

- High-quality graphic reproduction for retail packaging

For brands that demand high-quality color printing or e-commerce packaging with clean logos, these machines deliver outstanding results.

3. Precise Slotting and Die Cutting for Perfect Box Shapes

Accuracy is critical when producing corrugated boxes, especially when working with custom die-cut designs or delicate structural packaging.

Slotter precision

- Servo-controlled scoring and slotting

- Perfect alignment with printing patterns

- Adjustable slotting knives for different box sizes

Highly accurate rotary die cutting

- Complex shapes cut cleanly

- Smooth edges without tearing

- Repeatable accuracy across long production runs

This is especially valuable for FMCG brands, e-commerce packaging, electronic packaging, and custom-shaped boxes.

4. Reduced Labor Costs and Lower Human Error

Labor shortages and rising wages have made automation more important than ever.

A fully automatic flexo printer slotter die cutter:

- Requires fewer operators

- Automatically calibrates sheet feeding, printing registration, and cutting precision

- Minimizes waste due to human error

- Makes the entire production more stable and predictable

Factories that adopt automation commonly reduce operational labor by 30–50%.

5. Faster Setup, Changeovers, and Job Switching

Modern customers often place small-batch or multi-SKU orders. This means machines that take too long to adjust will waste hours every week.

A fully automatic model allows:

- Quick automatic order setup

- Digital storage of job parameters

- Auto adjustment of printing cylinders, slotting knives, and die-cut units

- ''One-button'' changeover

This dramatically improves efficiency for factories handling diverse order sizes.

6. Smarter Operation With Intelligent Control Systems

Today's fully automatic flexo printer slotter die cutters come with advanced control systems such as:

- Full servo drive system

- Multi-touch HMI control panel

- Real-time monitoring

- Automatic error alerts

- Remote diagnostic support

These intelligent features reduce downtime and help even new operators manage the machine with confidence.

7. Greater Consistency and Reduced Material Waste

Raw materials such as corrugated sheets and inks have become more expensive. Automation ensures that every sheet is used efficiently.

How the machine reduces waste:

- Accurate sheet feeding reduces rejects

- Precise registration avoids misprinting

- Intelligent stacking minimizes sheet damage

- Automated settings reduce set-up waste

Businesses often see 5–15% lower material waste, which translates to significant savings annually.

Why Many Manufacturers Choose Our Solutions at Giant

At Giant, we design fully automatic flexo printer slotter die cutters specifically for modern corrugated production lines. What sets our systems apart is our focus on reliability, long-term stability, and smart automation.

We use full-servo drive technology

This ensures faster response, smoother motion, and less mechanical wear.

Our machines offer true one-button job changeover

Ideal for factories dealing with frequent design changes.

We prioritize print quality

High-precision anilox rolls and advanced ink control help maintain sharp, vibrant graphics.

Comprehensive support and customization

Since every factory has different needs, we help customers select suitable printing units, die-cutting modules, stacker configurations, and smart features based on their production scale.

Rather than pushing a product, we work with each customer to build the ideal solution for their long-term growth.

Long-Term ROI and Lower Total Cost of Ownership

Investing in a fully automatic flexo printer slotter die cutter may seem costly at first, but the long-term benefits far outweigh the initial expense.

Key ROI contributors:

- Higher productivity

- Less labor cost

- Reduced waste

- Longer machine lifespan

- Lower maintenance due to full-servo system

- Shorter delivery times → more orders

Most factories recover their investment within 1–3 years.

Perfect for Small, Medium, and Large Carton Manufacturers

Whether you're running a high-volume factory or producing custom corrugated boxes, fully automatic machines offer flexibility and scalability.

Ideal for:

- E-commerce packaging

- Food and beverage cartons

- Electronics packaging

- FMCG brands

- Industrial shipping cartons

- Custom die-cut boxes

Their ability to handle multiple box styles makes them a universal solution for modern manufacturing.

Conclusion

A fully automatic flexo printer slotter die cutter is no longer a luxury—it's becoming a necessity for packaging manufacturers seeking efficiency, precision, and long-term competitiveness. With advanced automation, superior print quality, intelligent control, and seamless multi-process integration, these machines help factories dramatically upgrade their production capabilities.

At Giant, we've seen firsthand how upgrading to full automation transforms productivity and reduces operational headaches. By offering flexible configurations, reliable components, and ongoing technical support, we strive to help manufacturers stay ahead in an increasingly demanding market.

If you're considering boosting your production capacity or moving toward a smarter packaging factory, a fully automatic flexo printer slotter die cutter is one of the most impactful investments you can make.

FAQ About Fully Automatic Flexo Printer Slotter Die Cutters

1. What materials can the machine handle?

It is designed for corrugated cardboard sheets including single wall, double wall, and some heavy-duty boards.

2. How many operators do I need?

Typically 1–2 operators are enough because most processes are fully automated.

3. Can it print high-quality color graphics?

Yes. With modern anilox rolls and improved flexo technology, it can produce vivid, detailed images suitable for retail packaging.

4. How long does job changeover take?

Usually 2–5 minutes, thanks to automatic setting and digital memory.

5. Is the machine suitable for small-batch production?

Absolutely. Quick setup and high precision make it ideal for small-batch, multi-SKU orders.

6. What is the usual lifespan of the machine?

With proper maintenance, 10–15 years or more.

7. Do I need separate machines for printing and die cutting?

No. A fully automatic model integrates printing, slotting, and die cutting into one line.