Flatbed vs Corrugated Rotary Die Cutter: Which Is Better for Your Packaging Line?

In the modern packaging industry, efficiency, precision, and versatility are key factors in selecting the right die-cutting equipment. Two of the most popular solutions for corrugated board processing are flatbed die cutters and corrugated rotary die cutters. Both have their advantages, but understanding their differences, applications, and return on investment is crucial for businesses seeking to optimize their packaging lines. As a manufacturer with extensive experience in packaging machinery, at Giant, we often help clients navigate this decision, ensuring they select the right machine for their specific production needs.

Understanding Flatbed Die Cutters

Flatbed die cutters have long been a staple in corrugated packaging operations. These machines work by pressing a die onto a stationary sheet of corrugated board, cutting it into the desired shape. They are particularly valued for their precision, ability to handle thick boards, and flexibility for short runs or customized box designs.

Some of the key benefits of flatbed die cutters include:

- High Cutting Accuracy: The flatbed design allows for precise cutting, which is ideal for intricate designs or specialty packaging such as luxury cartons or high-end displays.

- Versatility in Material Handling: Flatbed machines can handle single-wall, double-wall, or even triple-wall corrugated boards, making them suitable for heavy-duty packaging.

- Custom Box Production: For clients producing short runs of custom boxes, flatbed die cutters are unmatched in their ability to quickly switch dies and accommodate unique designs.

However, flatbed die cutters are typically slower than rotary systems and may require more manual labor, especially for high-volume operations. This is where corrugated rotary die cutters come into play.

Understanding Corrugated Rotary Die Cutters

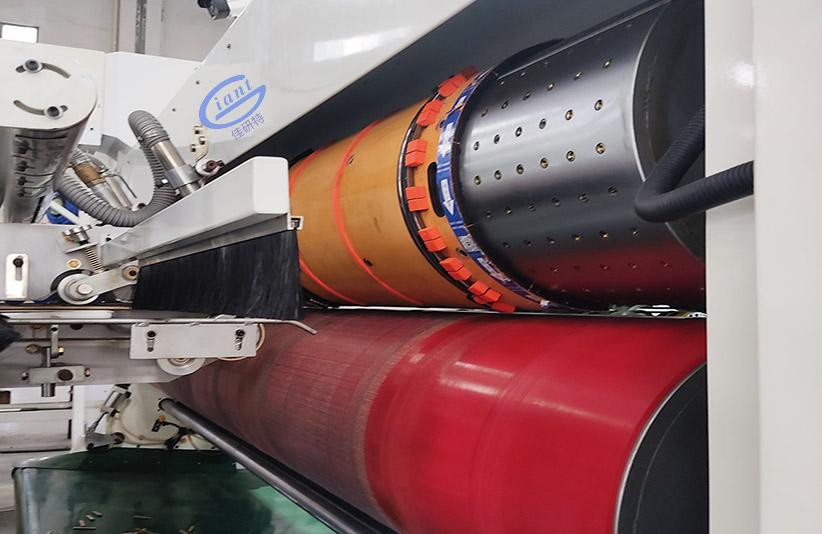

Corrugated rotary die cutters are designed for high-speed, continuous production of corrugated boxes. They use a rotating cylindrical die that continuously cuts and creases corrugated sheets as they pass through the machine. This makes them an ideal choice for manufacturers focusing on large-scale production, high efficiency, and reduced labor costs.

The main advantages of rotary die cutters include:

- High-Speed Production: Rotary machines can produce thousands of boxes per hour, significantly boosting throughput for large packaging lines.

- Consistency and Precision: Once set up, rotary die cutters maintain consistent cutting quality across large production runs, minimizing waste.

- Integration with Printing and Folding: Many rotary systems can be integrated with flexo printing units or folder-gluer machines, creating a complete automated packaging line.

At Giant, we have developed a range of corrugated rotary die cutters that balance speed and precision. By combining servo-driven controls and modular designs, our machines offer fast die changes, minimal downtime, and the flexibility to handle multiple box sizes and types, helping clients achieve maximum efficiency in their packaging operations.

Key Differences Between Flatbed and Rotary Die Cutters

Choosing between flatbed and rotary die cutters largely depends on your production goals. Here are the primary differences:

- Production Volume: Flatbed die cutters excel in low-to-medium volume or specialty runs, while rotary die cutters dominate high-volume operations.

- Setup and Changeover Time: Flatbed machines require more frequent die changes and manual adjustments, whereas rotary systems offer quicker setup and easier integration with automated lines.

- Material Flexibility: Flatbed machines handle thicker corrugated materials more effectively, whereas rotary systems are optimized for standard single-wall or double-wall boards.

- Operational Costs: Rotary die cutters offer lower labor costs per unit for high-volume runs, but the initial investment is generally higher compared to flatbed machines.

Choosing the Right Machine for Your Packaging Line

When deciding which die cutter suits your production needs, consider the following factors:

- Volume and Speed Requirements: If your packaging line produces large volumes of standard corrugated boxes daily, a rotary die cutter is often more cost-effective. For specialty products or frequent design changes, a flatbed machine is more suitable.

- Board Type and Thickness: Evaluate the type of corrugated board you use. Flatbed machines are more forgiving with thicker or multi-wall boards.

- Automation and Integration: Rotary die cutters can be integrated with upstream and downstream machinery, creating a seamless automated workflow that reduces labor and improves efficiency.

- Budget and ROI: While rotary die cutters require a larger initial investment, their high-speed production and low operational costs can deliver a faster return on investment for large-scale operations.

How Giant Helps Businesses Optimize Die Cutting

At Giant, we understand that every packaging line has unique requirements. That's why we offer both flatbed and corrugated rotary die cutters, tailored to different production needs. Our rotary die cutters are designed for high-volume, fast-paced environments, with features such as servo-driven motors, automated die changing, and precision cutting mechanisms. For clients needing flexibility in custom designs or short runs, our flatbed machines provide high accuracy and versatile material handling, ensuring that no box design is too complex.

By working directly with clients, we ensure that the selected die cutter matches their production volume, material type, and workflow, helping them achieve maximum efficiency and consistent product quality. Our goal is not only to provide machinery but also to support businesses in building a complete, reliable, and future-proof packaging line.

Conclusion

Both flatbed and corrugated rotary die cutters have their distinct advantages. The best choice depends on your production volume, material types, desired automation level, and overall business goals. Flatbed machines are ideal for precision, versatility, and custom packaging, while rotary die cutters excel in speed, consistency, and high-volume production.

At Giant, we pride ourselves on providing expert guidance and high-quality machinery to help manufacturers optimize their packaging lines. By carefully evaluating your needs, we can recommend the right solution—whether it's a flatbed or rotary die cutter—ensuring your business achieves efficiency, precision, and growth in today's competitive packaging market.