FEEDING UNIT:

| Name |

Specification |

| Feeding system |

Lead edge Feeding system |

| Zero position |

Automatic |

| Total counter |

Touch screen display |

| Machine speed |

Touch screen display |

| Sheet clearer |

Suction bolower & brush for sheet cleaning |

| Side guide position |

Motorized,0.2kwX2ea,Touch screen display |

| Front stop position |

Motorized,0.1kw,by jog switch |

| Back stop position |

Motorized,0.2kw,by jog switch |

| Feed roll nip control |

Motorized,0.2kw,Touch screen display |

| Unit open/close |

Motorized,0.4kw,by jog switch |

| Lower suction blower |

7.5 kw |

| Main motor |

Inverter control:37kw |

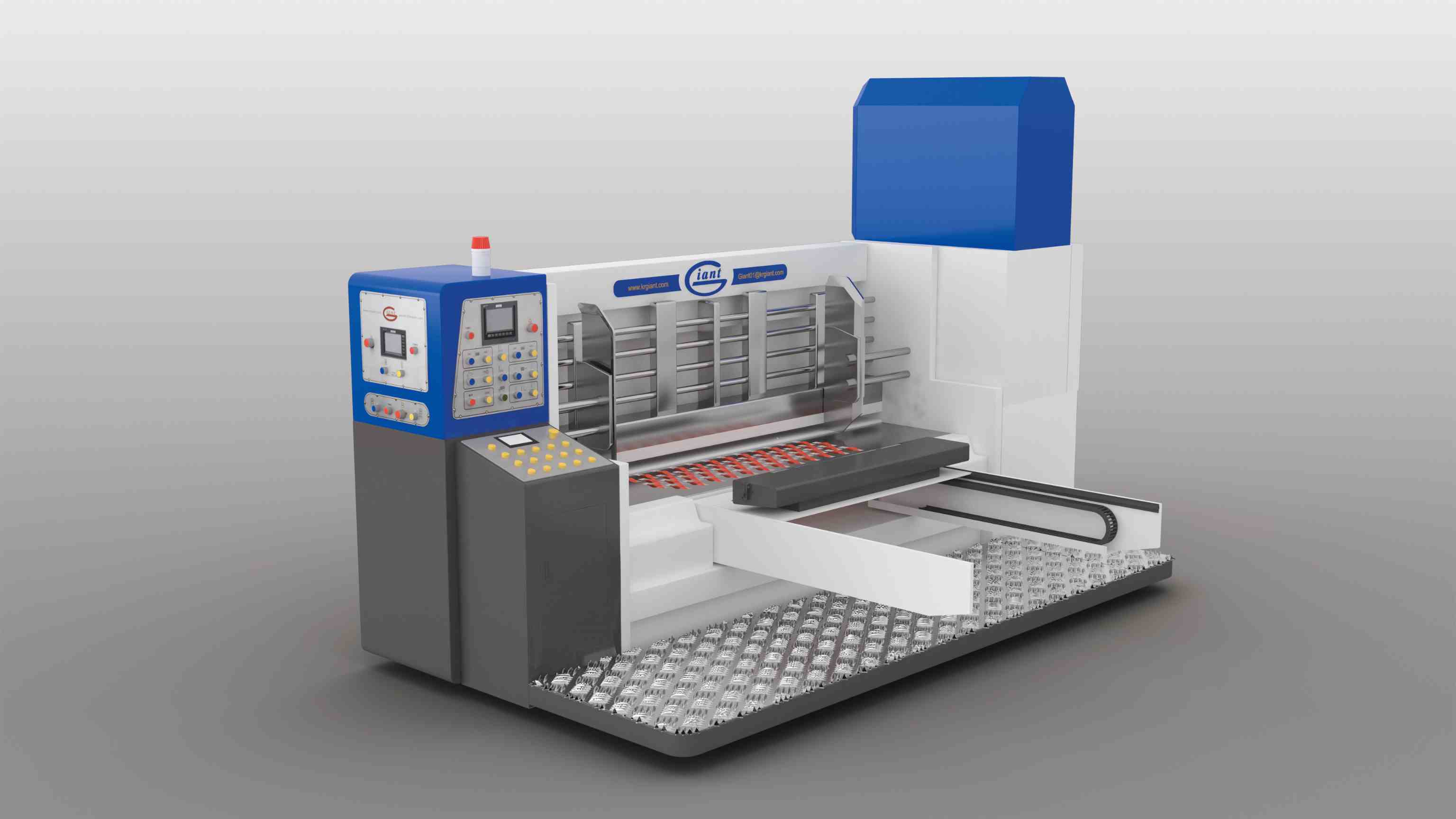

PRINTING UNIT (TOP PRINTING) :

| Name |

Specification |

| Top printing system |

optional |

| Bottom printing system |

optional |

| Vacuum transfer system |

optional |

| Ceramic anilox roller |

optional |

| Chamber Doctor blade |

optional |

| Doctor roller inking system |

Diaphragm type ink pump |

| Register System |

Printing registeris digital controlled by motor and PLC |

| |

Easy to control by means of reset "0" system |

| Zero position |

Automatic |

| Print cylinder register |

Motorized 0.4kw,Touch screen display |

| Print cylinder side control |

Motorized 0.2kw,Touch screen display |

| Impress roll nip control |

Motorized 0.2kw,Touch screen display |

| Pull roll nip control |

Motorized 0.2kw,Touch screen display |

| Anilox roller clearance |

Motorized 0.1kw,Touch screen display |

| Doctor roller clearance |

Motorized 0.2kw,Touch screen display |

| Doctor roller motor |

Geared 0.4kw |

| Gear box oil level |

Automatic control (Allunit the same) |

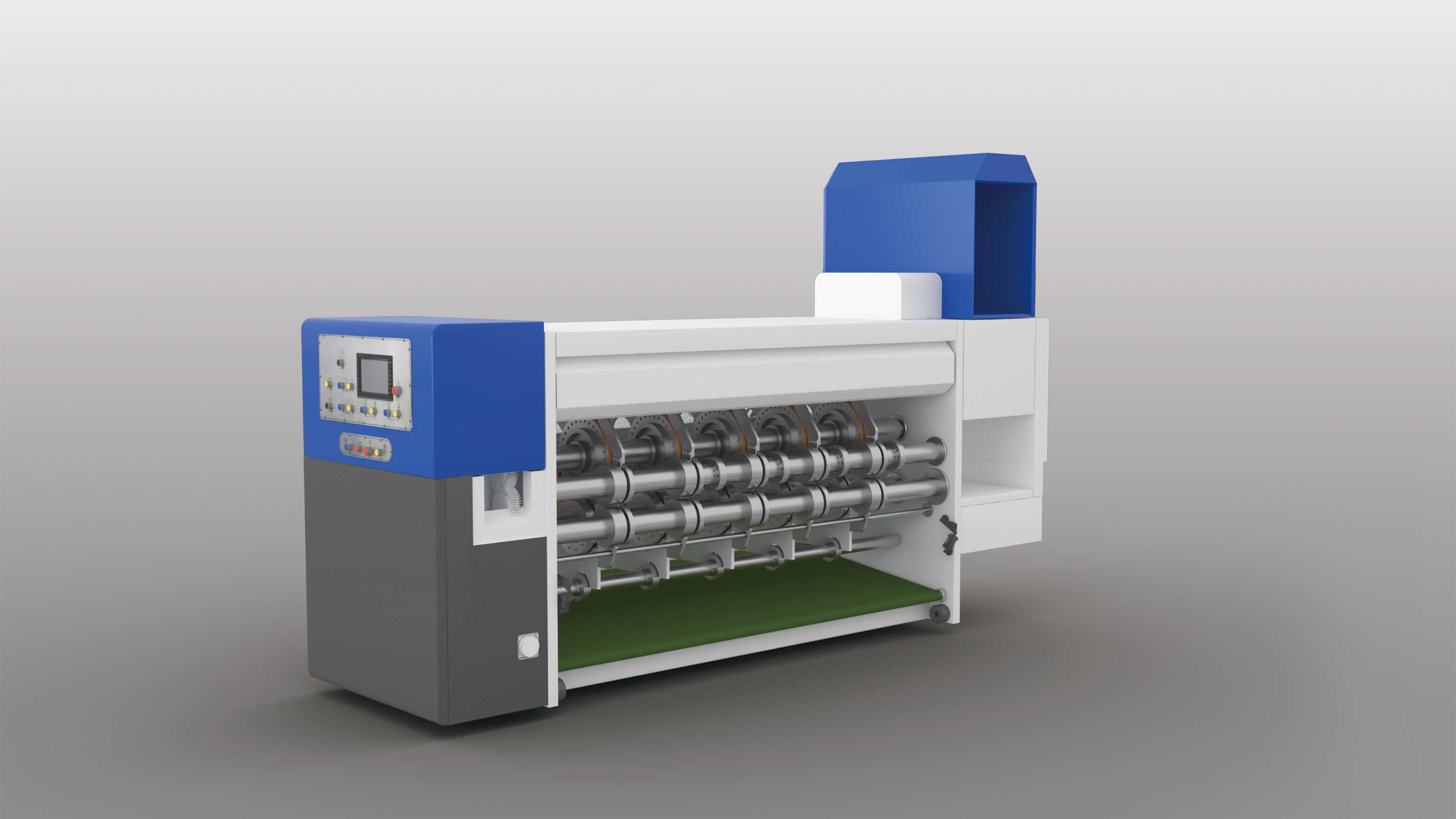

SLOTTING UNIT (DAUL SLOTTING):

| Name |

Specification |

| Dual slot system |

No need mechanical adjustment for biggercarton height |

| Zero position |

Automatic |

| Panel size |

Motorized(0.4kwx 4ea),Touch screen display |

| Slot depth size |

Motorized(0.4kw),Touch screen display |

| Box height size |

Motorized(0.4kw),Touch screen display |

| Cleaser nip control |

Motorized,0.2kwTouch screen display |

| Slotter nip control |

Motorized,0.2kw,Touch screen display |

| Scrap conveyor |

0.4kw |

DIE CUTTING UNIT (TOP PRINTING BOTTOM CUTTING) :

| Name |

Specification |

| Zero position |

Automatic |

| Die roll register |

Motorized 0.4kw,Touch screen display |

| Die roll side control |

Motorized 0.2kw,Touch screen display |

| Anvil roll transversal movement |

Automatic 70mm |

| Anvil roll clearance |

Motorized 0.4kw,Touch screen display |

| Pull roll nip control |

Motorized 0.2kw,Touch screen display |

| Scrap conveyor |

0.4kw |

DRYER UNIT :

·IR Dryer

·Hot air dryer

·Vacuum transfer system

Ceramic coating vacuum trance roll

Automatic control in gearbox oil level

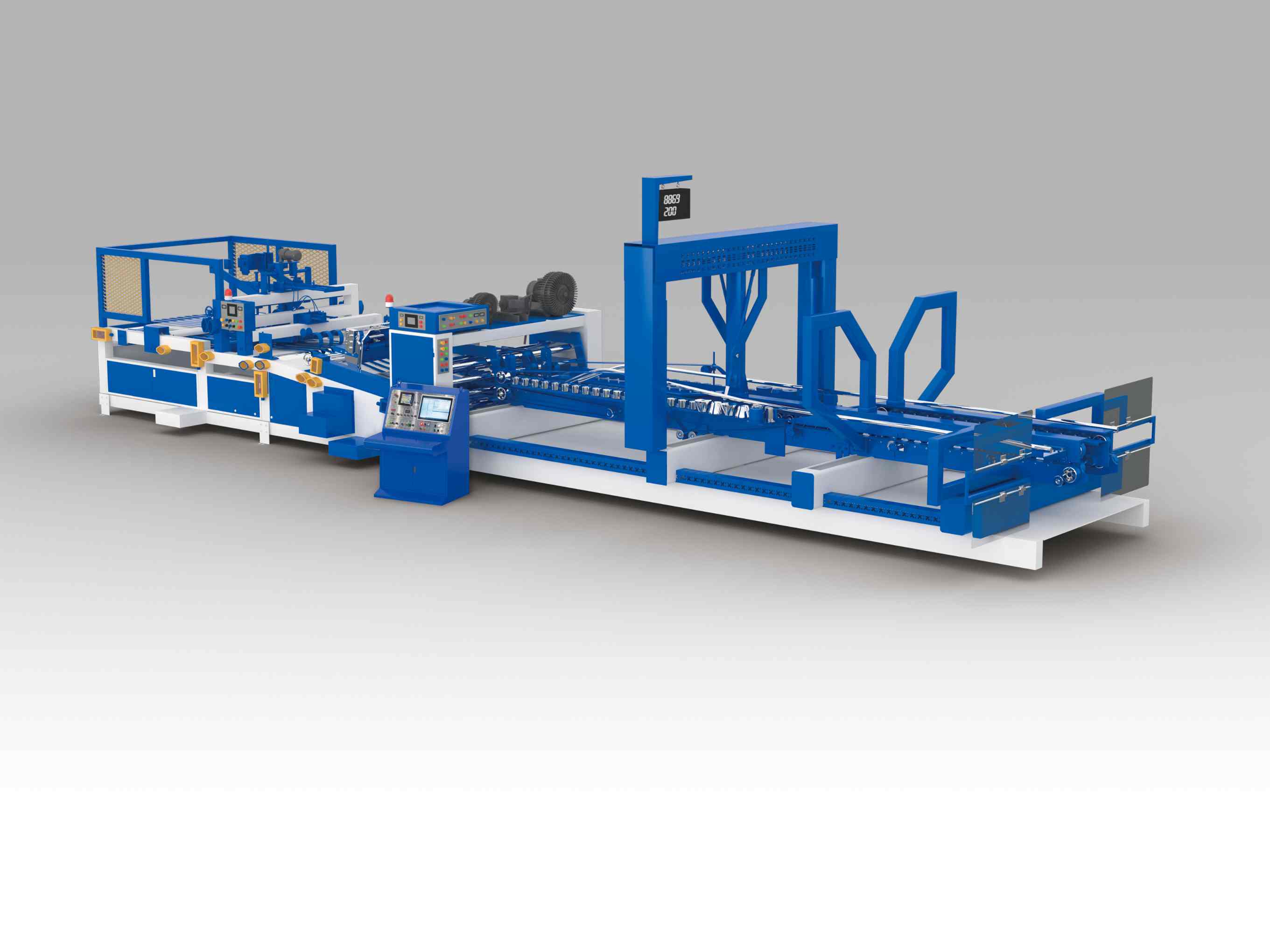

Folder Gluer Counter Ejector(Made in Korea)

Gluer/Stitcher Folder&Counter Ejector Unit(Made in Korea):

| Name |

Specification |

| Down folding system |

Optional |

| Up folding system |

Optional |

| Belt transportation system |

With guide, bar leads the carton box andmakes folding more accurate |

| Box squaring system |

|

| Main motor |

AC 15kw,inverter control |

| Side guide positation |

0.4kw X 2ea, touch screen display |

| Glue head position |

0.4kw X 1ea,touch screen display |

| Pusher |

0.75kw |

| Suction blower |

2.2kw X2ea, 1.5kw X 1ea |

| Bottom stacking system |

The boxes stack from bottom to top |

| Suction belt conveyor |

For the best conveying accuracy |

| Count ejector system |

For high speed production |

| Main motor |

7.5kw |

| Front stop position |

0.4kw,touch screen display |

| Back stop position |

0.4kw, touch scereen display |

| Ejecting line control |

Touch screen display |

| Center line control |

0.4kw |

| Suction blower |

2.2kw |

| Belt conveyor |

0.75kw |

| Name |

Specification |

| Down folding system |

Optional |

| Up folding system |

Optional |

| Belt transportation system |

With guide, bar leads the carton box andmakes folding more accurate |

| Box squaring system |

|

| Main motor |

AC 15kw,inverter control |

| Side guide positation |

0.4kw X 2ea, touch screen display |

| Glue head position |

0.4kw X 1ea,touch screen display |

| Pusher |

0.75kw |

| Suction blower |

2.2kw X2ea, 1.5kw X 1ea |

| Bottom stacking system |

The boxes stack from bottom to top |

| Suction belt conveyor |

For the best conveying accuracy |

| Count ejector system |

For high speed production |

| Main motor |

7.5kw |

| Front stop position |

0.4kw,touch screen display |

| Back stop position |

0.4kw, touch scereen display |

| Ejecting line control |

Touch screen display |

| Center line control |

0.4kw |

| Suction blower |

2.2kw |

| Belt conveyor |

0.75kw |

Counter Ejector (Madein Korea):

Twice flapping and stacking method effectively buffer the carton production speed, so theproduction speed for

the three-layer carton and five-layer carton is completely same. The rear production can equipped with inline automatic strapper, saving labor and improving production efficiency.

The up folding can effectively adapt to the folding production of various large-size cartons.

Company Activities