Why Automatic Box Stitching Machines Are Essential for Corrugated Packaging?

As the global demand for corrugated packaging grows—driven by industries like e-commerce, food delivery, and logistics—manufacturers are constantly seeking faster, more efficient, and more reliable ways to assemble and secure carton boxes. In this context, automatic box stitching machines have become a vital component of modern packaging operations.

Unlike manual or semi-automatic methods, automatic box stitching machines offer unparalleled precision, speed, and consistency. For manufacturers aiming to improve productivity while reducing labor and waste, investing in such equipment is no longer a luxury—it's a necessity.

This article explores the critical role automatic stitching machines play in the corrugated packaging industry, their key benefits, and why a professional, order-driven manufacturer like Giant is the ideal partner for your stitching machine needs.

What Is an Automatic Box Stitching Machine?

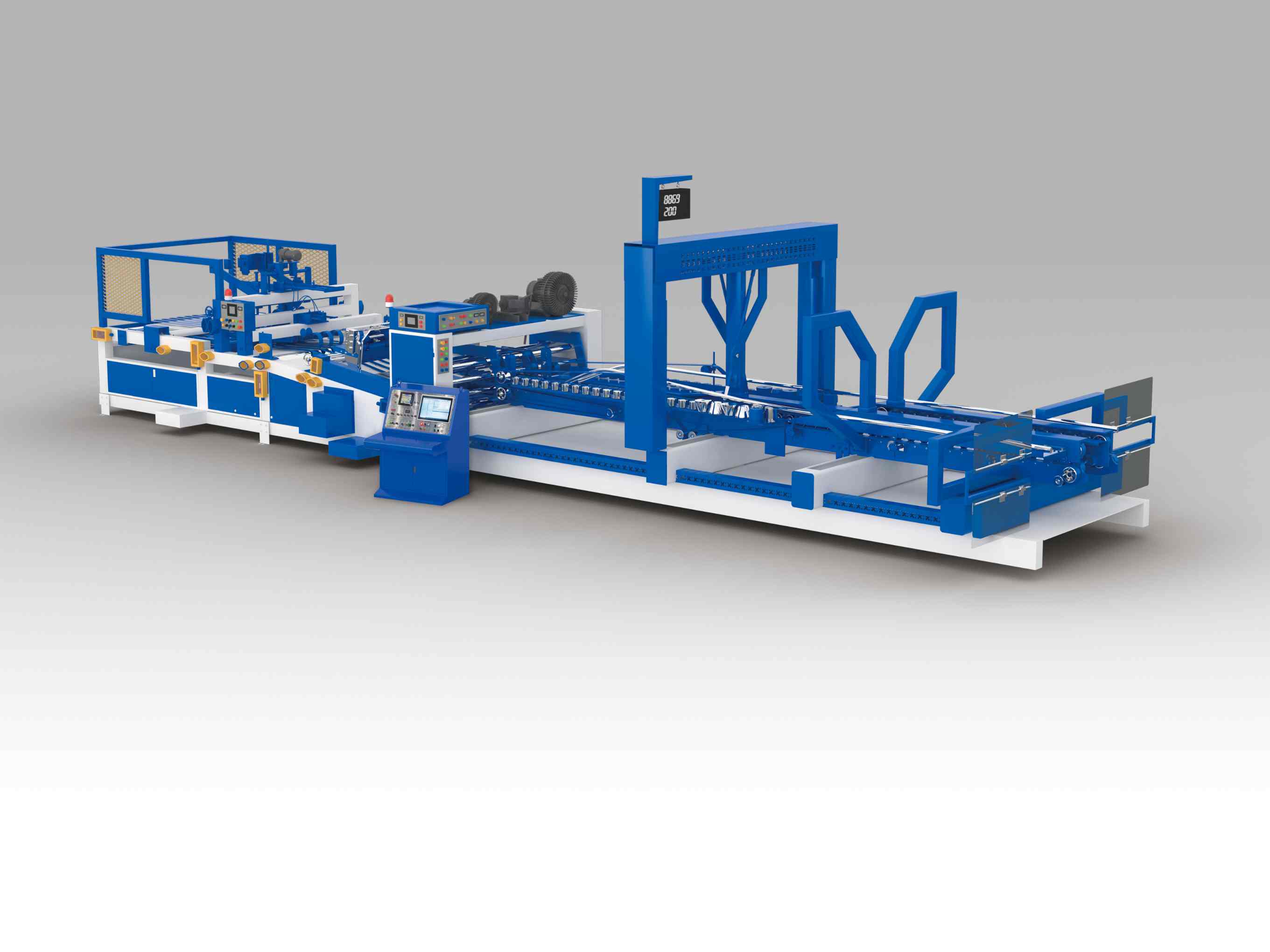

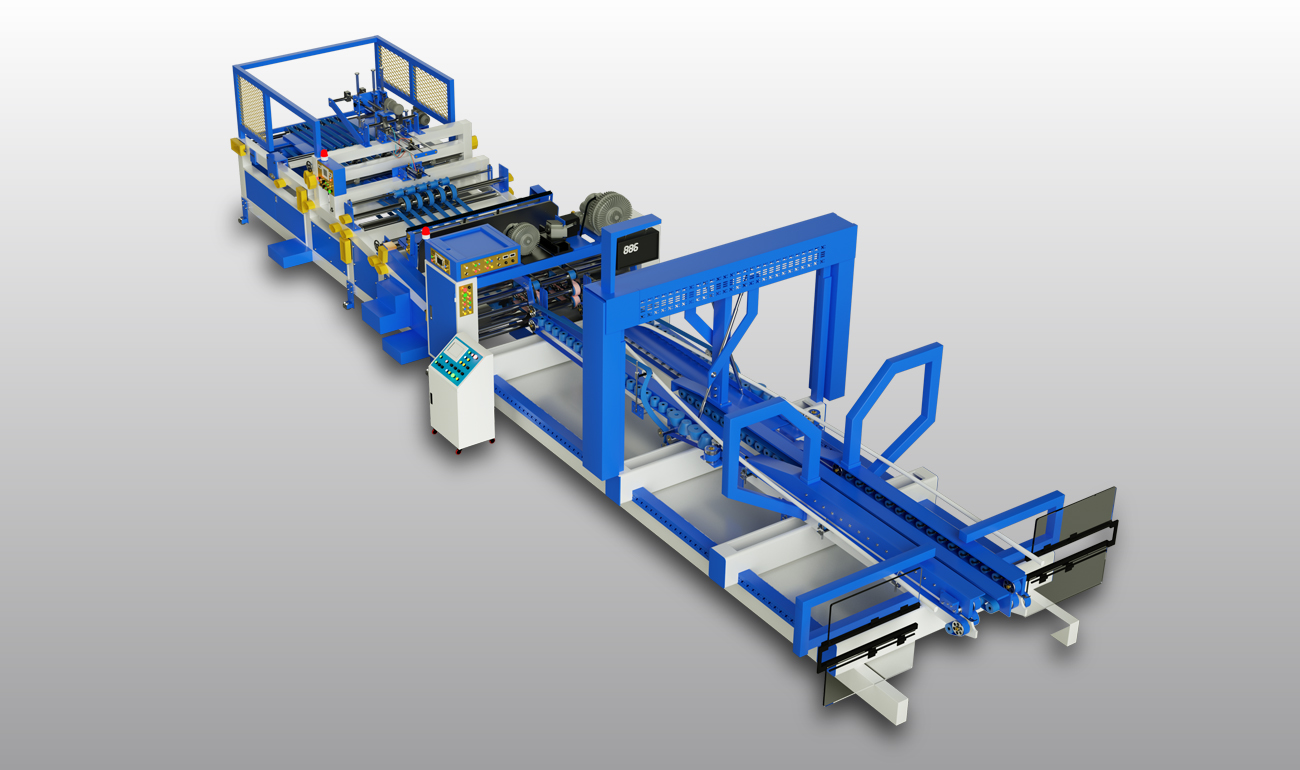

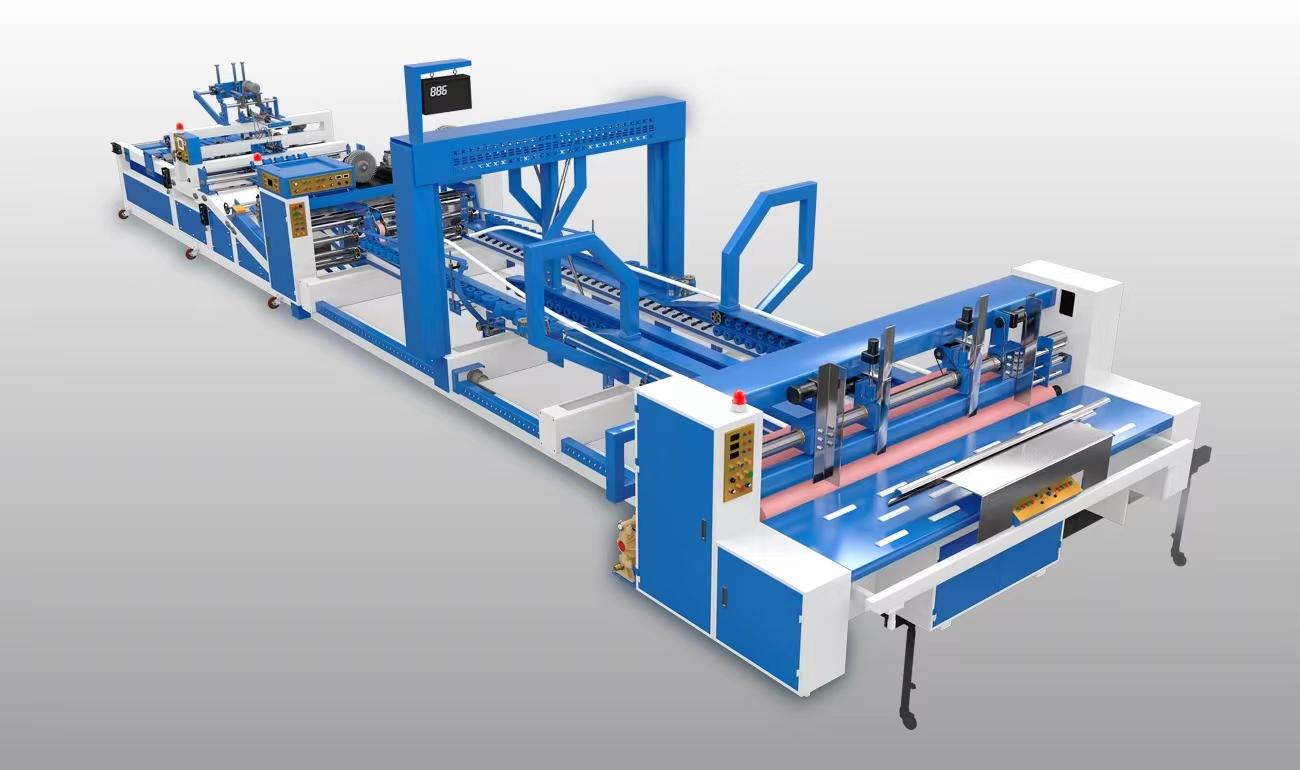

An automatic box stitching machine (sometimes called an automatic carton stitching machine) is a piece of industrial equipment designed to join the flaps of corrugated boxes using metal staples or stitching wires. These machines automate the entire process—from box feeding and positioning to stapling and stacking—providing a continuous, high-speed, and uniform stitching operation.

Capable of handling various corrugated board grades (such as single-wall, double-wall, and triple-wall), these machines are a core component of carton box production lines in factories, warehouses, and large-scale packaging plants.

Why Automatic Box Stitching Machines Matter in Corrugated Packaging

1. Boosts Productivity and Output

One of the most significant advantages of automatic stitching machines is their output efficiency. While a manual operator may complete a few boxes per minute, an automatic system can stitch 30–60 boxes or more in the same timeframe. This efficiency helps businesses scale operations and fulfill high-volume orders with ease.

2. Ensures Uniform and Secure Stitching

Manual stitching often leads to inconsistencies—uneven spacing, weak staples, or misalignment—that can compromise the box's structural integrity. In contrast, automatic machines deliver precise, repeatable, and tightly controlled stitching every time, ensuring the boxes remain durable throughout shipping and storage.

3. Reduces Labor Dependency

With rising labor costs and ongoing labor shortages in many manufacturing hubs, automation becomes the most logical path forward. An automatic box stitching machine reduces reliance on manual labor while improving consistency, allowing your team to focus on other high-value tasks in the production process.

4. Minimizes Waste and Rework

Poor stitching can result in box damage, wasted materials, and costly rework. Automatic machines help reduce these risks by delivering accurate and clean stitching, minimizing the chance of errors or scrap. Many machines also feature automatic detection systems to ensure alignment and fault prevention.

5. Adapts to Diverse Box Sizes and Applications

From small retail cartons to oversized industrial containers, box stitching machines can be configured to accommodate a variety of box sizes, shapes, and thicknesses. This versatility makes them essential across industries including:

- Food and beverage

- Furniture and appliances

- Consumer electronics

- Agricultural packaging

- Logistics and warehousing

Key Features of a Reliable Automatic Stitching Machine

When selecting a box stitching machine, businesses should look for features that ensure both operational flexibility and long-term value:

- Servo motor control systems for accuracy and efficiency

- Adjustable stitching pitch and depth for various board thicknesses

- Touchscreen HMI panels for intuitive operation and job setup

- High-speed performance with minimal downtime

- Optional integration with auto-feeding and stacking systems

These features not only enhance productivity but also support scalability as your packaging demands evolve.

Why Choose Giant as Your Box Stitching Machine Supplier?

When it comes to sourcing dependable and high-performing automatic carton stitching machines, choosing the right manufacturer is just as important as choosing the right machine.

Giant stands out in the packaging equipment sector by offering a unique combination of customization, full-process production control, and an order-based manufacturing model that adapts to each client's specific requirements.

What Makes Giant Different?

1. Custom-Built Solutions for Your Exact Needs

Unlike mass-production brands offering generic models, Giant specializes in made-to-order solutions. Each machine is produced based on your actual box specifications, production speed needs, and layout requirements. This approach ensures you get a machine that's optimized for your operation, not a one-size-fits-all product.

2. End-to-End Production Line Manufacturing

Giant operates its own complete in-house manufacturing line, giving us full control over quality, parts integration, and delivery timelines. From frame welding and electrical assembly to final calibration and testing, every component is handled internally, ensuring consistency and performance at every stage.

3. Order-Driven Manufacturing Model

Instead of stocking large inventories of machines, Giant adopts an on-demand production strategy. This lean model enables us to allocate resources efficiently and prioritize product customization, allowing you to get the features you truly need—without paying for what you don't.

4. Flexible Integration with Your Packaging Process

Because every Giant machine is built to order, we can easily integrate it into your existing packaging line or help design a complete end-to-end setup. Whether you need your machine to sync with folding-gluing units, printing stations, or automated stackers, we design for seamless operation.

5. Reliable Support and Long-Term Partnership

Giant is committed to more than just selling machines—we focus on building long-term partnerships. From consultation and technical training to after-sales support and future upgrades, our team ensures your stitching equipment continues to perform reliably over time.

Automation Is the Future of Corrugated Box Production

Corrugated packaging isn't going anywhere—in fact, it's growing rapidly in response to shifts in retail and logistics. To stay competitive in this environment, manufacturers must adopt modern, automated tools that reduce cost, improve output, and guarantee consistent quality.

Automatic box stitching machines are at the heart of this transformation. Whether you're upgrading from manual processes or expanding your packaging capacity, the right machine will be a long-term asset that pays for itself many times over.

And when it comes to customized, durable, and reliable stitching equipment, Giant is the partner of choice for companies that demand quality without compromise.

Conclusion

From increasing productivity to ensuring box integrity, automatic box stitching machines have become essential tools in corrugated packaging manufacturing. They offer the performance, consistency, and cost-efficiency that today's production lines require.

For businesses looking to upgrade their packaging process, investing in a tailored solution from Giant means getting more than just a machine—you gain a strategic partner with the expertise, infrastructure, and commitment to support your long-term growth.