Ultimate Guide to Corrugated Intelligent Flexo Printer Slotter Die Cutters in 2025

In the fast-paced world of corrugated packaging, efficiency, precision, and automation are no longer optional —they're essential. As demand for customized, high-quality corrugated boxes surges, more manufacturers are turning to corrugated intelligent flexo printer slotter die cutters to stay competitive. In this ultimate guide, we'll walk you through everything you need to know about these high-performance machines in 2025 — from core components and technology trends to key benefits, buying considerations, and why Giant's solution stands out in the market.

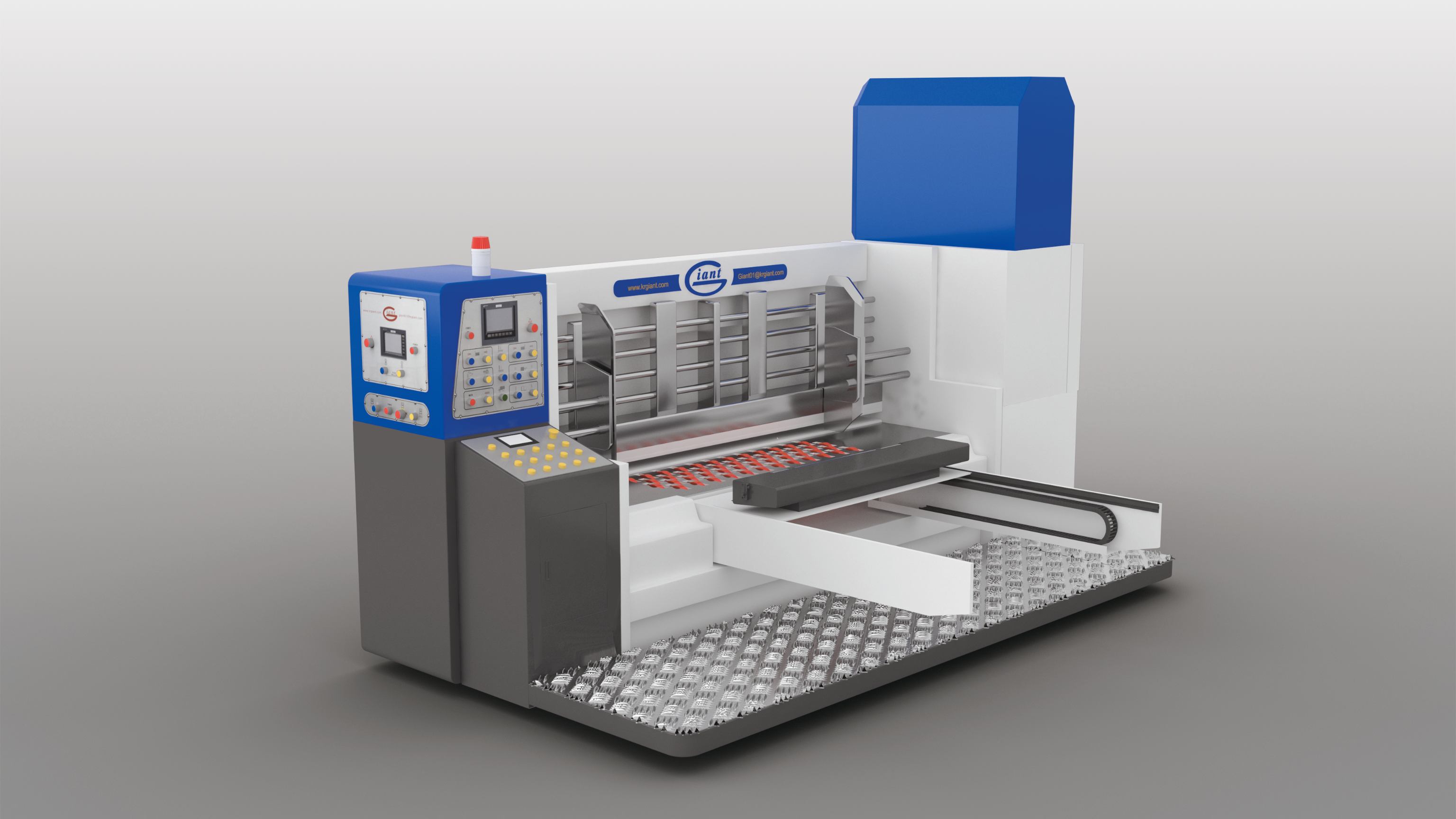

What Is a Corrugated Intelligent Flexo Printer Slotter Die Cutter?

A flexo printer slotter die cutter is a multifunctional machine that integrates flexographic printing, slotting (creasing), and rotary die-cutting in a single production line. By combining these functions, manufacturers can convert corrugated board (single-wall, double-wall, etc.) into printed, die-cut cartons with minimal manual handling. This drives higher throughput and consistent quality.

When we refer to it as ''intelligent,'' we're highlighting modern enhancements such as servo control, automatic registration, touchscreen touch‑panel operation, memory functions, and advanced diagnostics. These features allow smart control over parameters like slot depth, panel size, and die registration, making production more flexible and efficient.

Key Components & Technology Trends in 2025

1. Flexographic Printing Unit

- Modern machines support 2‑color, 3‑color, or even 4‑color multi-color flexo printing, enabling full-color graphics or brand designs.

- Use of water-based or UV inks improves eco-friendliness and drying times.

- Precision is achieved via a servo-controlled registration system for accurate print alignment.

2. Feeding Unit

- High-speed lead-edge feeding with vacuum transfer systems ensures stable and consistent board feeding.

- Automatic front/back side guides and motorized nip control reduce human error.

- Touchscreen controls enable easy setup, repeatability, and memory for frequent jobs.

3. Slotting / Creasing Unit

- Dual-slot knife system allows accurate slotting and creasing for complex carton designs.

- Automatic adjustment of slot depth and box height via touchscreen makes the process more flexible.

4. Die Cutting Unit

- Rotary die-cutting: Anvil roll and die cylinder with motorized registration ensure clean, precise cuts.

- Motorized locking and transfer control make it easy to swap dies and maintain alignment.

5. Drying / Curing Unit

- IR (infrared) dryer combined with hot-air dryer ensures efficient drying without smudging.

- Vacuum transfer with ceramic-coated rolls helps maintain board stability and quality during drying.

6. Intelligent Control & Automation

- Touchscreen PLC or HMI (Human Machine Interface) for easy operation.

- Memory save function allows quick job recalls and reduces setup times.

- Servo motors and PLC systems optimize precision and minimize waste.

- Automatic gearbox oil-level monitoring helps ensure machine longevity.

Why Invest in a Corrugated Intelligent Flexo Printer Slotter Die Cutter in 2025

Efficiency & Productivity Gains

By integrating printing, slotting, and die-cutting, intelligent flexo slotter die cutters eliminate multiple passes and manual transfers, significantly speeding up production. This all-in-one solution reduces labor costs and minimizes the risk of misalignment or registration errors.

High Print Quality & Flexibility

With multi-color flexo printing and accurate registration systems, you can deliver high-resolution, brand-grade packaging. The flexibility to switch between different designs, slot depths, and die cuts means you can handle a wide variety of box styles — RSC (Regular Slotted Containers), die-cut designs, e-commerce cartons, and more.

Material & Waste Optimization

Modern machines like those from Giant are designed for minimal material waste. Precision slotting and cutting mean scoring and trimming are more accurate, and any waste falls away cleanly. Intelligent control systems also help minimize ink waste and reduce board misfeeds.

Automation & Labor Savings

Touchscreen interfaces, memory functions, and automatic adjustments reduce manual intervention and make it easier for operators to run repeat jobs. Servo-driven systems ensure consistency, even at high speeds.

Reliability & Durability

Built with robust components, these machines are designed for long-term industrial use. Brands like Giant emphasize durability, with features such as automatic gearbox oil-level control to extend machine life.

Safety & Compliance

Modern intelligent flexo machines are often CE-certified and designed with operator safety in mind. Automated controls reduce manual handling, and well-engineered feeding and cutting systems lower the risk of accidents.

Key Considerations When Buying

When evaluating corrugated intelligent flexo printer slotter die cutters, here are several critical factors to weigh:

Production Volume & Speed Needs

How many sheets/min do you need? Giant's models can range (e.g., 100–350 sheets/min depending on size).

Do you need high-speed printing or moderate speeds are sufficient?

Color Requirements

Do you need 2‑color, 3‑color, or 4‑color printing?

Will you use water-based or UV inks?

Corrugated Board Specification

What flute types (A, B, C, double-wall) do you use? Giant machines support various corrugated board types.

What sheet size range will you be processing? (check min/max size, e.g., Giant's GMVP series specs)

Automation & Memory Features

Do you require job memory and repeatability for frequent order changes?

Does the machine support touch‑screen configuration and servo control?

Post-Processing Needs

Do you want inline integration (e.g., folder gluer, stitcher, counter‑ejector)? Giant offers inline configurations.

Is die changeover frequent? How easy is it to swap dies?

Maintenance & After-Sales Support

What is the availability of spare parts?

Does the manufacturer (such as Giant) provide global technical support, training, and maintenance services?

Is the gearbox oil-level monitored automatically to reduce maintenance burdens?

Compliance & Certifications

Ensure the machine meets local safety and CE (or other relevant) certifications.

Assess whether the machine's energy efficiency or environmental footprint aligns with your sustainability goals.

Why Choose Giant's Corrugated Intelligent Flexo Printer Slotter Die Cutter?

When it comes to investing in a corrugated intelligent flexo printer slotter die cutter, Giant is a proven partner with a strong track record:

- Extensive Product Range: Giant offers flexo printer slotter die cutter machines in a variety of models (GMVP-0618 up to GMVP-1840), accommodating different sheet sizes, speeds, and production volumes.

- High Automation & Precision: Their machines integrate servo-driven registration, automatic zero return, and motorized creasing and cutting, resulting in consistently accurate production.

- All-in-One Integration: Options are available for inline systems that combine printing, slotting, die-cutting, gluing or stitching, and even stacking or counter ejector.

- Durability & Reliability: Designed with features like automatic gearbox oil-level control, vacuum feeding systems, and motorized units, Giant's machines are built to last and to operate with minimal downtime.

- Global Reach & Support: Giant supports customers worldwide, offering installation, training, spare parts, and technical assistance.

- Custom Solutions: Whether you need a machine optimized for high-speed e-commerce carton production or one tailored for high-quality, multi-color branding packages, Giant can deliver customized configurations.

Challenges & Solutions in Real-World Use

Challenge 1: High Initial Investment

Solution: Calculate ROI by factoring in labor savings, reduced waste, and increased throughput. Because machines like Giant's integrate multiple steps (print, slot, cut) into one line, the long-term savings often justify the upfront cost.

Challenge 2: Skill Gap for Operators

Solution: Invest in operator training. Giant typically provides training, commissioning, and after-sales support to ensure operators are proficient in using ''intelligent'' features like servo registration and touchscreen interfaces.

Challenge 3: Die Changeover Time

Solution: Use memory functions and standardized tooling. Modern machines support quick die changes, and having repeat job memories minimizes setup time for returning customers.

Challenge 4: Maintenance Needs

Solution: Follow a preventive maintenance plan. Use features like automatic gearbox oil-level monitoring, regular cleaning of the drying unit (IR/hot-air), and routine inspection of slotting blades to ensure consistent performance.

Future Trends & Innovations to Watch

- Increased Automation & Industry 4.0 Expect tighter integration with MES (Manufacturing Execution Systems), IoT sensors, and predictive maintenance. Intelligent flexo slotter die cutters will become part of smart packaging lines.

- Sustainable Inks & Materials As environmental regulations tighten, more manufacturers will push for water-based inks, recyclable corrugated substrates, and energy-efficient drying systems.

- Digital-Analog Hybrid Lines Some forward-looking corrugated producers may combine digital printing with flexo slotter die cutting to handle both short‑run custom jobs and high-speed mainstream production.

- Enhanced Versatility More machines will support modular upgrades — allowing a flexo printer slotter die cutter to evolve into a full inline folder‑gluer stitcher as a business grows.

Conclusion

In 2025, a corrugated intelligent flexo printer slotter die cutter represents one of the most advanced and cost-effective investments for any corrugated packaging business. By combining printing, slotting, and die‑cutting in a single, automated production line, these machines dramatically boost efficiency, reduce waste, and deliver high-quality, customizable corrugated boxes.

Giant, as an industry leader, offers a range of highly automated, precise, and reliable solutions tailored to different production needs. If you're ready to scale up, improve product quality, or streamline your carton-making process, partnering with Giant can give you a significant competitive advantage.