Troubleshooting Common Issues in Flexo Printing on Corrugated Substrates

Flexographic printing is the standard for corrugated packaging, including pizza boxes, paper cartons, and folding boxes, due to its speed, versatility, and cost-effectiveness. However, printing on corrugated substrates presents unique challenges that can affect print quality, color consistency, and production efficiency.

This article provides a comprehensive guide to troubleshooting common flexo printing issues on corrugated boards. We will cover substrate considerations, ink problems, printing plate maintenance, registration challenges, and equipment settings. By understanding these factors, manufacturers can minimize waste, reduce downtime, and maintain consistent high-quality results.

Understanding Common Flexo Printing Issues on Corrugated Substrates

Printing on corrugated board is different from printing on smooth paper. The texture, thickness, and composition of the substrate can influence ink absorption, registration, and overall print quality. Common issues include:

- Ink Smearing or Set-Off

- Uneven Ink Coverage

- Board Crushing or Warping

- Registration Errors

- Color Fading or Poor Opacity

Each of these problems has specific causes and solutions, which we will discuss in detail.

Ink Smearing and Set-Off

Ink smearing occurs when the ink does not dry quickly enough or is applied too heavily. This can be caused by:

- Using incorrect ink viscosity for corrugated substrates

- Inadequate drying time or temperature

- Excessive printing pressure

Solutions:

- Adjust ink formulation and viscosity to match the corrugated board type

- Use energy-efficient drying systems like hot-air or infrared dryers

- Reduce nip pressure to prevent over-inking

Uneven Ink Coverage

Uneven or patchy ink coverage results in inconsistent colors, dull graphics, and poor brand presentation. Causes include:

- Worn or dirty anilox rollers

- Incorrect plate impression

- Uneven substrate surface

Solutions:

- Regularly clean and inspect anilox rollers to maintain uniform ink transfer

- Adjust plate pressure and ensure proper mounting

- Select corrugated boards with smooth surfaces for high-resolution graphics

Board Crushing and Warping

Flexo presses apply pressure to ensure proper ink transfer, but excessive pressure can crush the corrugated flutes or warp the board. This affects print clarity and structural integrity.

Solutions:

- Optimize roller pressure according to board thickness and flute type

- Maintain consistent tension across the substrate

- Use presses with servo-driven tension control to minimize distortion

Registration Errors

Multi-color printing requires precise alignment of each color layer. Misregistration can result from:

- Poor tension control

- Plate misalignment

- Substrate stretching

Solutions:

- Employ automatic registration systems and inline inspection cameras

- Calibrate plates accurately during changeover

- Maintain stable environmental conditions to reduce board expansion

Color Fading and Poor Opacity

Color fading or lack of opacity can occur due to:

- Substrate absorption

- Insufficient ink density

- Incompatible ink type for kraft or corrugated boards

Solutions:

- Use high-opacity inks for darker substrates

- Apply primers if necessary

- Adjust ink viscosity and density for consistent color saturation

Preventive Measures for Reliable Flexo Printing

To minimize common flexo printing issues, manufacturers should focus on:

- Regular Maintenance: Clean rollers, inspect plates, check ink viscosity

- Substrate Selection: Use quality corrugated boards appropriate for high-resolution printing

- Equipment Calibration: Optimize pressure, tension, and registration

- Operator Training: Skilled operators reduce errors and waste

- Eco-Friendly Ink Use: Water-based inks reduce smudging and comply with food safety standards

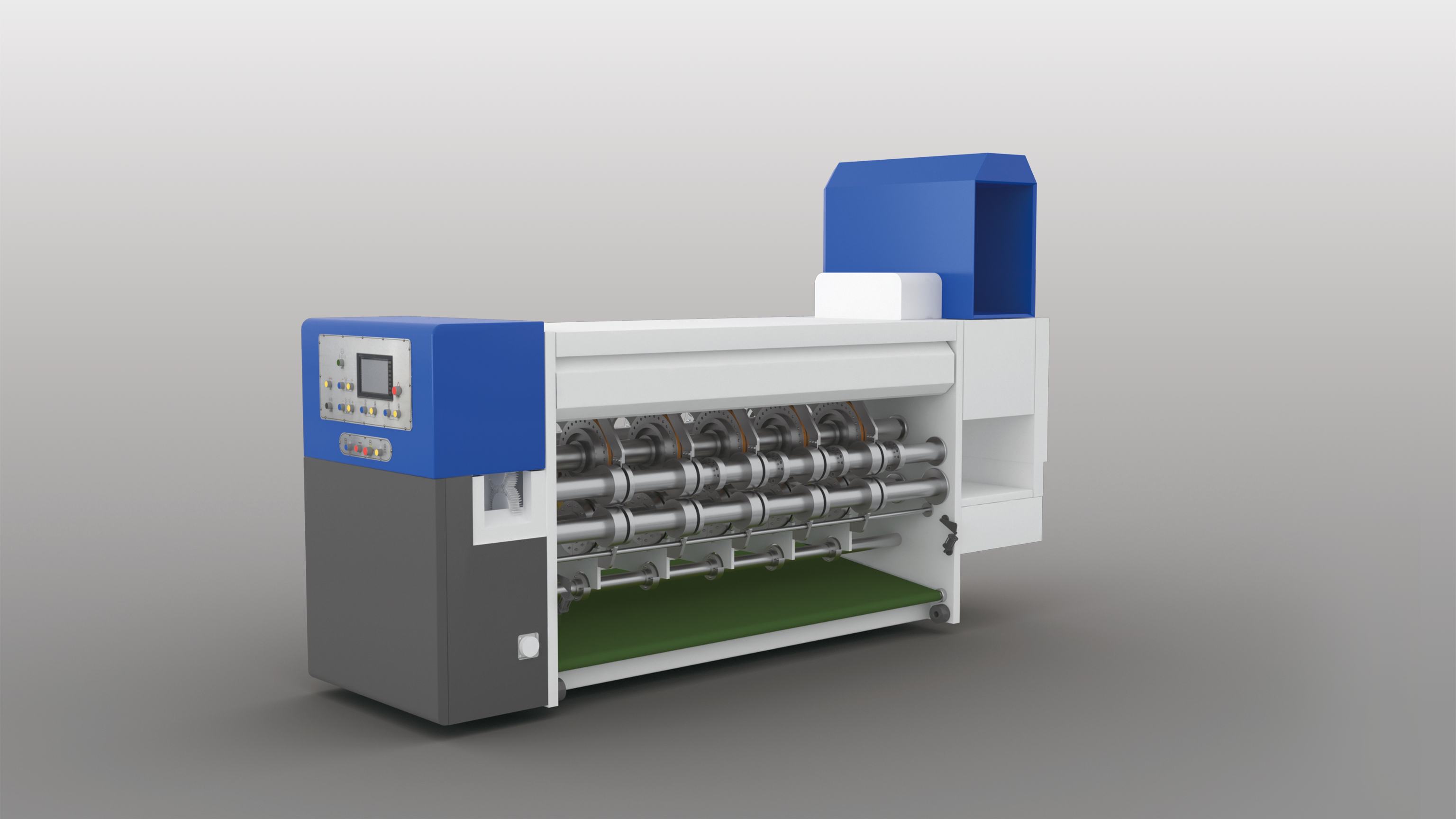

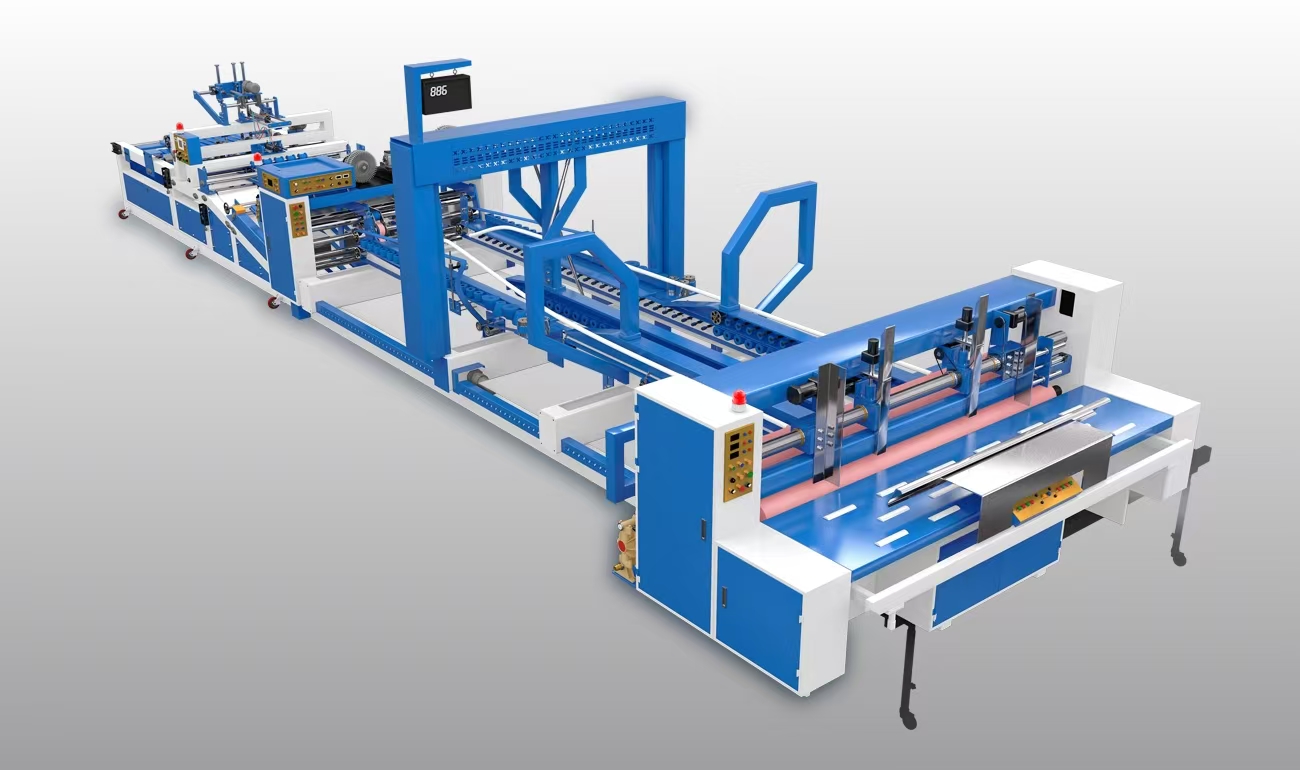

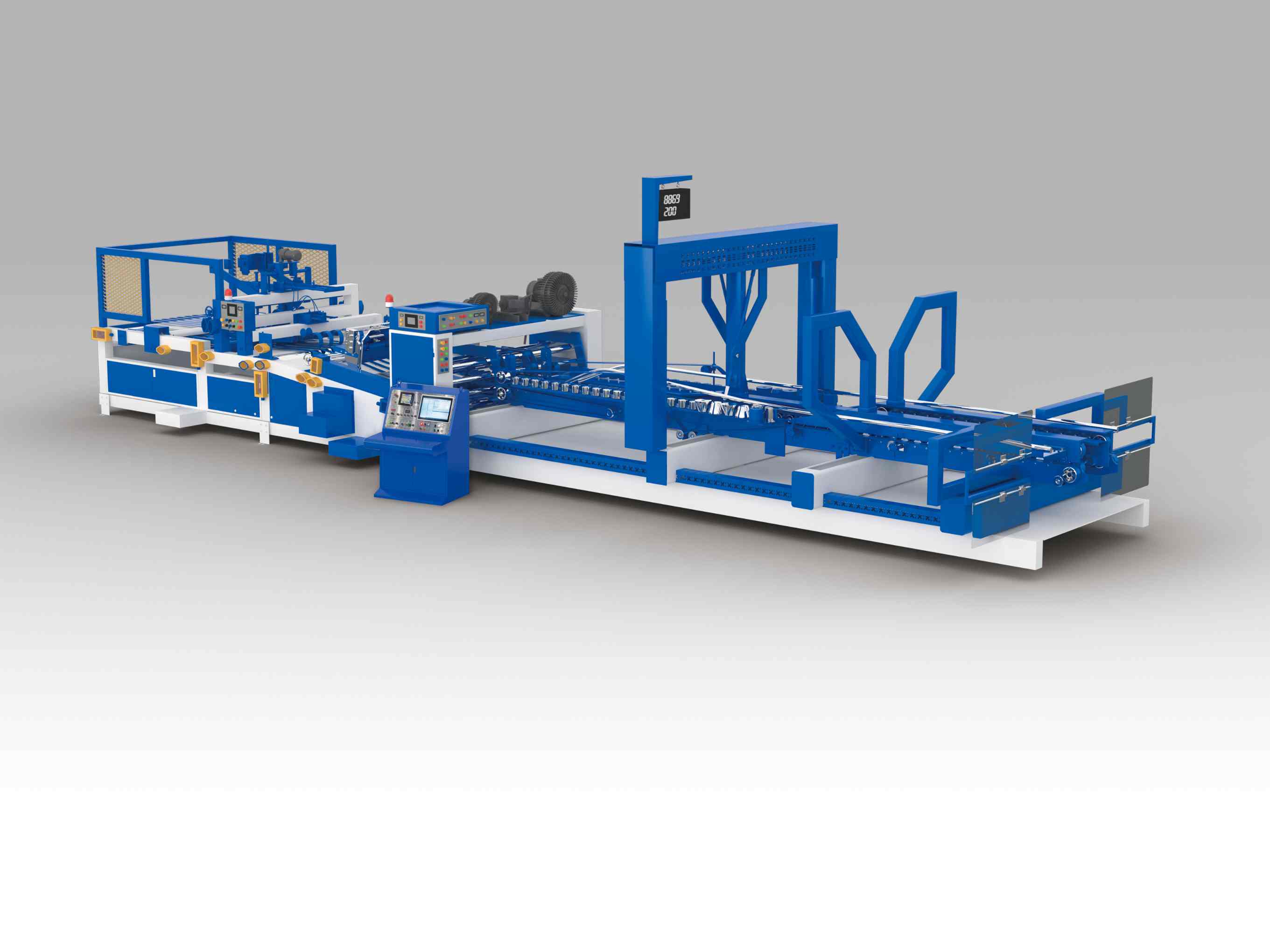

Using Giant's flexographic printing machines ensures that all these preventive measures are supported by reliable, high-performance equipment designed for corrugated packaging. Giant machines integrate drying, registration, and slotting systems, allowing manufacturers to produce consistent, high-quality prints efficiently.

Why Choose Giant for Corrugated Flexo Printing

Giant is a trusted provider of flexo printing presses for corrugated packaging, including pizza boxes, folding cartons, and specialty paper boxes. Our machines are designed for:

- High-speed production with minimal waste

- Integrated slotting and die-cutting for complete workflows

- Compatibility with food-safe, water-based inks

- Low maintenance and user-friendly operation

By choosing Giant, manufacturers can reduce downtime, prevent common printing defects, and maintain consistent brand quality.

Conclusion

Flexographic printing on corrugated substrates is a reliable method for high-volume packaging production, but it comes with unique challenges. By addressing ink smearing, uneven coverage, board crushing, registration errors, and color fading, manufacturers can ensure professional, high-quality prints.

Using advanced flexo presses from Giant, packaging producers gain the tools and technology to troubleshoot issues efficiently, reduce waste, and achieve consistent results across every batch. This leads to improved productivity, enhanced brand presentation, and greater customer satisfaction in the competitive packaging industry.