Top 5 Benefits of Using a High-Speed Printing Machine in 2025

In the fast-growing packaging and corrugated box industry, speed and quality are no longer optional—they are essential. As e-commerce, custom packaging, and retail branding continue to expand in 2025, manufacturers need solutions that can deliver high-volume production with consistent quality.

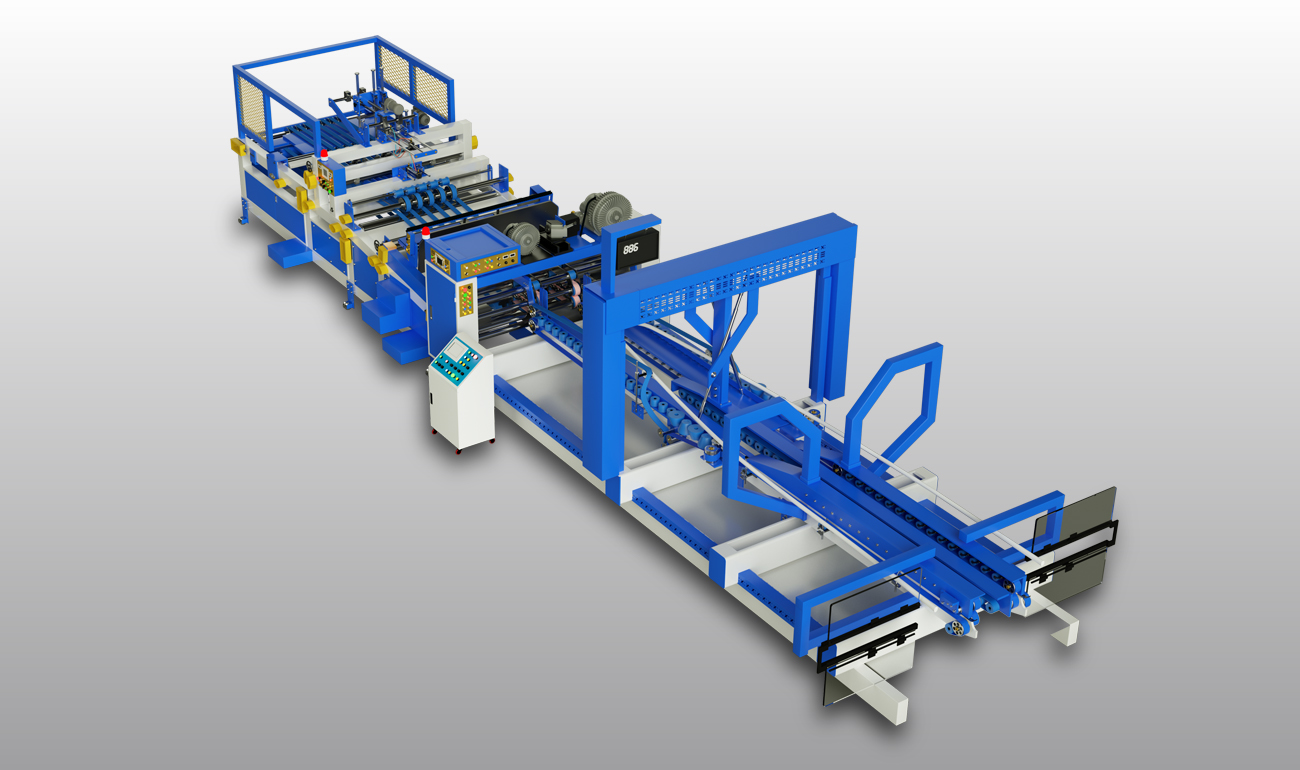

A high-speed printing machine—whether a flexographic press or an integrated printing and converting system—can dramatically improve output, reduce labor costs, and future-proof your operations. In this guide, we'll cover the top 5 benefits of high-speed printing machines in 2025 and explain why leading manufacturers like Giant are trusted partners worldwide.

1. Massively Increased Production Speed and Throughput

The most immediate benefit of a high-speed printing machine is its ability to handle large volumes of work at exceptional speed. While traditional machines may max out at 60-100 sheets per minute, modern high-speed flexographic printing machines can easily reach 200-400 sheets per minute, depending on configuration and substrate type.

For manufacturers producing:

- Corrugated shipping boxes

- Custom retail cartons

- Pizza boxes

- Color-printed display packaging

This level of speed translates to higher output with less manpower.

High-speed printers eliminate bottlenecks in production lines, allowing for more seamless integration with slotter die cutters, folder gluers, and counter ejectors—resulting in fully automated, continuous operations.

2. High-Definition Printing Quality and Brand Consistency

Speed is important, but not at the expense of quality. In 2025, customers expect clean, vibrant, and sharp branding on every package. Thanks to advanced anilox rollers, auto registration systems, and intelligent ink management, today's high-speed flexo printers deliver exceptional print resolution even at maximum speed.

These machines support multi-color printing, UV or water-based inks, and can handle fine-line graphics, logos, QR codes, and even retail-grade CMYK full-color prints. This is especially critical for:

- Consumer electronics packaging

- FMCG (Fast Moving Consumer Goods) products

- Food and beverage cartons

- Branded e-commerce boxes

In an era where packaging is a key part of marketing, maintaining consistent and high-quality printing gives your business a professional, trustworthy image.

3. Reduced Labor Costs and Lower Waste

One of the most practical advantages of upgrading to a high-speed printing and converting machine is automation. Older printing presses often require constant human intervention—for feeding sheets, adjusting ink levels, or correcting misalignment. In contrast, high-speed printers feature

- Servo-controlled automatic feeding systems

- Touchscreen operation panels

- Real-time diagnostics and smart alerts

- Automatic ink level monitoring

These innovations reduce the need for manual adjustments and minimize errors, leading to fewer reprints, less paper waste, and lower ink consumption.

Key financial benefits include:

- Lower labor requirements

- Faster job setup and changeovers

- More predictable maintenance intervals

- Better material yield

When combined with an integrated slotting, folding, stitching, and counter ejection system, your entire production line becomes smarter and leaner.

4. Flexibility Across Multiple Materials and Box Designs

Modern packaging demands flexibility. From lightweight e-commerce mailers to sturdy double-wall shipping cartons, customers want variety. High-speed printing machines are designed to adapt to various substrates, including

- Corrugated board (single-face, single-wall, double-wall)

- Kraft linerboard

- Coated and uncoated duplex board

- Laminated papers and recycled materials

Additionally, high-speed printers can quickly switch between box sizes, die patterns, and print layouts without extended downtime. This makes them ideal for companies offering custom packaging solutions, short-run jobs, and on-demand printing.

Use cases include:

- Small-batch branded packaging for startups

- Multi-size box printing for 3PL providers

- Product-specific seasonal packaging

5. Smart Technology Integration and Future-Readiness

2025 marks a significant turning point in Industry 4.0 adoption in the packaging sector. High-speed printing machines now feature integrated IoT connectivity, cloud-based analytics, and AI-driven controls.

Leading brands, like Giant, offer machines with:

- Predictive maintenance via sensor data

- Remote diagnostics and software updates

- Smart job scheduling based on production analytics

- Centralized monitoring for multi-line factories

This level of intelligence gives you the ability to optimize performance in real-time, reduce unplanned downtime, and scale your packaging operations more efficiently. As demand grows for customization, traceability, and eco-friendly practices, high-speed machines help future-proof your business.

Why Choose Giant for Your High-Speed Printing Needs?

When it comes to investing in reliable, high-performance, and scalable packaging equipment, Giant stands out as a global leader. With years of experience in the corrugated box machinery industry, Giant provides an extensive range of:

- Flexo printer slotter die cutters

- Automatic folder gluer stitcher counter ejectors

- High-speed corrugated printing presses

- Fully integrated box making machines

Giant's machines are engineered for precision, durability, and maximum uptime, making them the preferred choice for packaging manufacturers in Asia, Europe, and the Americas.

By choosing Giant, you gain:

- Responsive global support

- Custom configurations to match your needs

- Competitive pricing with long-term ROI

- Integration with your existing packaging lines

For companies serious about scaling their production, reducing waste, and enhancing brand quality, Giant offers the most dependable and future-ready solutions on the market.

FAQ

1. How fast is a high-speed corrugated printing machine in 2025?

Modern flexo machines run 200–400 sheets per minute, depending on configuration and substrate.

2. Can high-speed printers maintain print quality at full speed?

Yes. With auto-registration and anilox technology, they deliver sharp multi-color prints without compromise.

3. What materials can high-speed printing machines handle?

They support kraft liners, corrugated board, duplex board, and recycled substrates.

4. Are high-speed printing machines eco-friendly?

Yes. Many models use water-based inks, energy-efficient motors, and waste-reduction systems.

5. Which brand is best for corrugated high-speed printing machines?

Giant is a leading supplier, offering flexo and fully automated converting systems with global after-sales service.

Conclusion

In 2025, investing in a high-speed printing machine is not just about keeping up with demand—it's about leading the market. From faster production and consistent branding to lower costs and smart factory integration, the benefits are undeniable.

With cutting-edge technology and reliable support, Giant high-speed printing machines empower packaging manufacturers to scale production, reduce waste, and deliver world-class packaging quality.