Printing Pizza Boxes: Key Considerations for Flexo & Corrugated Packaging

Pizza boxes are a common product, but producing high-quality printed boxes requires careful attention to the printing process. For packaging manufacturers, printing pizza boxes efficiently and with consistent quality is critical for branding, customer appeal, and sustainability.

Among available printing methods, flexographic printing on corrugated board has emerged as the industry standard due to its speed, versatility, and cost-effectiveness. This article explores the key considerations for printing pizza boxes using flexo and corrugated packaging solutions, including substrate choice, ink selection, plate technology, registration, and equipment setup.

Why Flexographic Printing is Ideal for Pizza Box Production

Flexographic, or ''flexo,'' printing employs flexible relief plates and fast-drying inks to transfer designs onto corrugated or kraft paperboard. It is widely used in corrugated packaging, pizza boxes, and folding cartons for several reasons.

High-Speed and Cost-Effective Printing

Flexo presses allow continuous printing, drying, and cutting in one process. This makes them ideal for high-volume pizza box production, ensuring speed without compromising quality.

Versatility with Corrugated and Kraft Materials

Pizza boxes are typically made from E-flute or B-flute corrugated board. Flexo presses accommodate these substrates easily, providing consistent ink coverage and reducing board crushing—an issue often seen with offset or digital printing methods.

Eco-Friendly and Food-Safe Printing

Modern flexo presses use water-based inks that are odorless, low in volatile organic compounds (VOCs), and safe for food packaging. These inks comply with global standards for sustainable food packaging, meeting both regulatory requirements and consumer expectations.

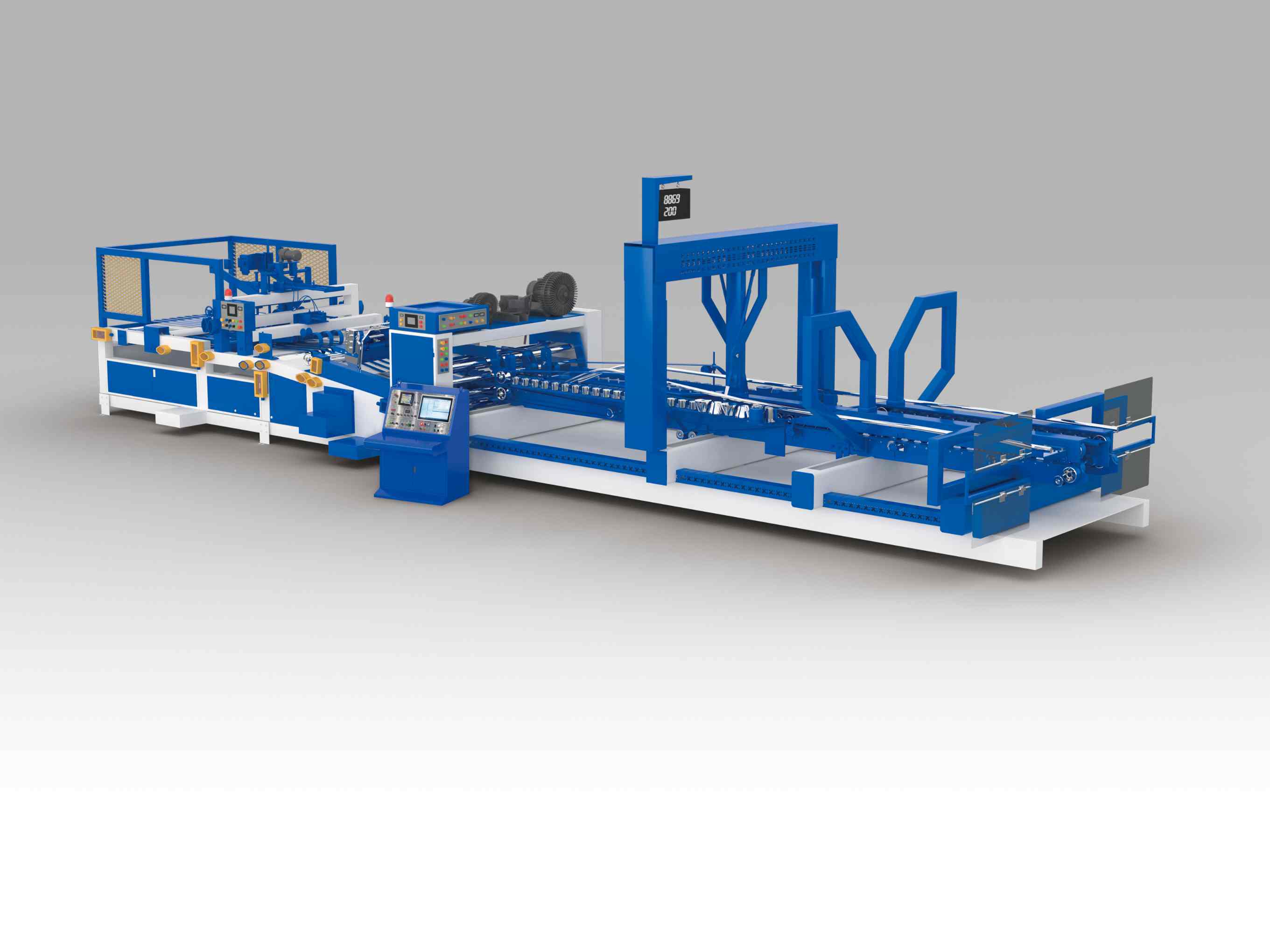

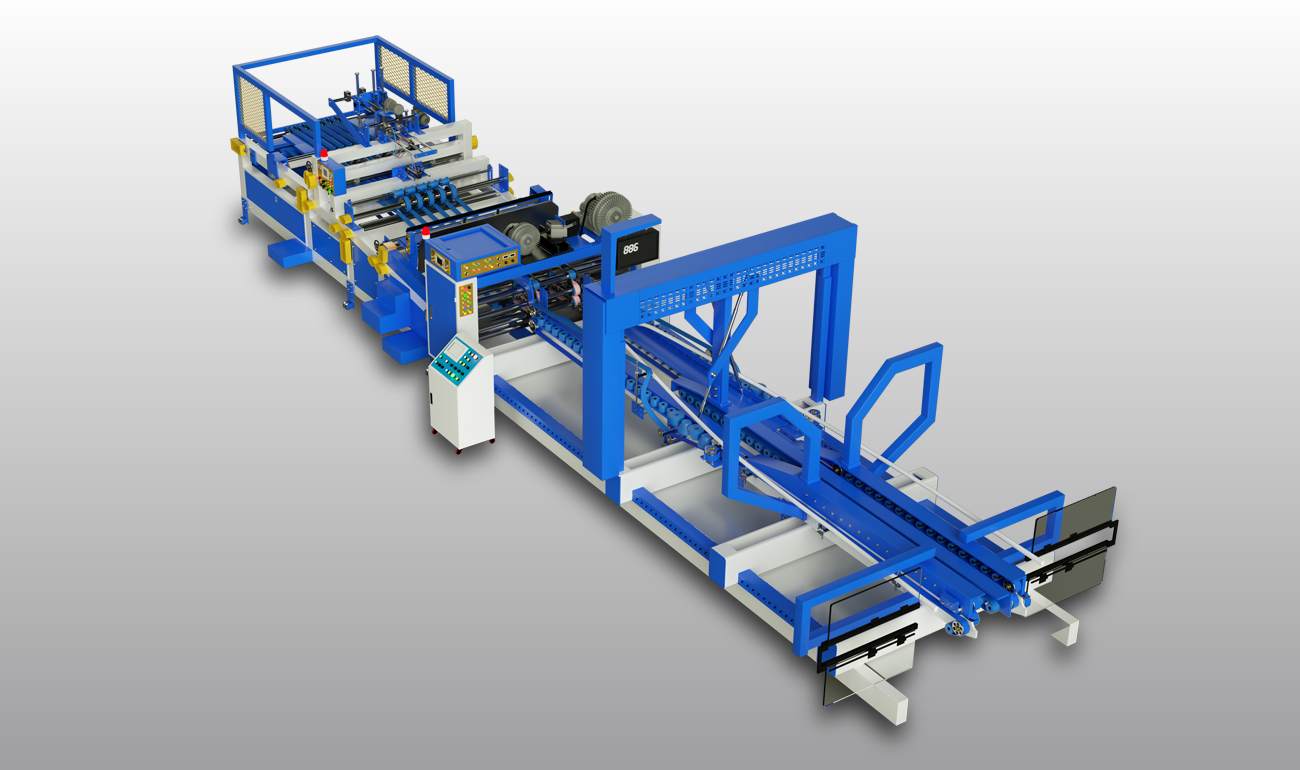

Integration with Cutting and Slotting

Advanced flexo presses can be paired with slotter and die-cutting machines, allowing a streamlined pizza box production line. This integration ensures accurate cutting, creasing, and folding alongside printing, increasing efficiency and reducing waste.

Key Considerations When Printing Pizza Boxes

Achieving high-quality results in pizza box printing requires attention to several technical factors.

Substrate Quality and Corrugated Structure

The choice of corrugated board, including flute type and liner weight, affects print clarity and durability. E-flute boards offer a smoother surface for high-resolution graphics, while B-flute boards provide extra strength but require careful impression control. Ensuring proper board caliper and surface smoothness minimizes ink absorption issues and enhances color consistency. Aligning the flute direction with the print direction prevents warping and misregistration.

Ink Selection and Adhesion

Ink choice is critical for pizza box printing. Water-based flexo inks are the preferred option due to their food safety, bright color output, and smudge resistance. High-opacity inks may be necessary for darker kraft boards to ensure logos and designs stand out. Proper ink formulation and viscosity adjustment can improve adhesion and drying performance, especially on corrugated substrates.

Printing Plate Technology

The photopolymer printing plate determines the sharpness and detail of printed graphics. Digital laser-engraved plates offer superior clarity, while regular maintenance prevents dot gain and color distortion. Flexo presses from Giant support quick plate changes, reducing downtime and improving daily output.

Registration and Color Accuracy

Multi-color pizza box designs require precise registration. Advanced flexo presses include features such as servo-driven tension control, automatic color registration, and inline inspection cameras. These ensure consistent color alignment and sharp edges at high production speeds, preserving brand quality and design integrity.

Drying Systems and Efficiency

Efficient drying systems are essential to prevent ink smearing and set-off. Infrared or hot-air dryers are commonly used, depending on ink type and substrate. Giant's flexo presses feature energy-efficient drying solutions that shorten production time while maintaining optimal color quality.

Integration with Slotter and Die-Cutting Units

After printing, pizza boxes must be slotted, die-cut, and folded accurately. Integrating a flexographic press with corrugated slotters ensures alignment throughout the production process. This integration reduces waste, ensures consistent cutting precision, and streamlines the workflow from raw board to finished pizza box. Giant's solutions are designed to handle this complete process, providing manufacturers with reliable, high-quality results.

Common Challenges and Solutions in Pizza Box Printing

Some common issues in pizza box printing include ink smearing, uneven coverage, board crushing, misregistration, and faded colors. These problems can be addressed by:

- Adjusting drying systems and ink formulation to prevent smearing

- Cleaning or replacing anilox rollers to maintain uniform coverage

- Optimizing roller pressure to avoid board crushing

- Using servo-driven or automatic registration systems to correct misalignment

- Applying primer or adjusting ink density to maintain color vibrancy

Careful attention to these factors ensures high-quality printed pizza boxes every time.

Why Choose Giant for Pizza Box Printing Solutions

As a leading flexographic printing machine supplier, Giant provides complete solutions for corrugated and pizza box production.

Giant machines are engineered for:

- High-speed, high-volume printing with minimal waste

- Integrated slotting and die-cutting for seamless production

- Compatibility with food-safe, water-based inks

- Reliable performance and low maintenance

For manufacturers of custom pizza boxes, folding cartons, or corrugated trays, Giant's flexo presses deliver consistent color, precise cutting, and improved efficiency, making them a trusted choice in the packaging industry.

Conclusion

Printing pizza boxes involves much more than applying logos and designs. Success requires careful consideration of substrate selection, ink performance, printing plate technology, registration, drying, and integration with finishing units.

By using advanced flexographic printing machines, such as those from Giant, packaging manufacturers can produce high-quality, eco-friendly pizza boxes efficiently, enhancing brand value and meeting market demand for sustainable packaging.