Pre Feeder vs Traditional Feeding Methods: Which Is Best for Modern Corrugated Production Lines?

As corrugated packaging rapidly evolves toward higher-speed, higher-volume, and more automated production, every component in a carton box making line must operate with precision and consistency. Among these components, the sheet feeding stage plays one of the largest roles in determining the actual performance of a flexo printer slotter die cutter and the overall stability of a corrugated production line.

In many factories, this leads to a critical question: Is it time to upgrade to a pre feeder, or can traditional feeding methods still support modern production requirements?

This article provides an in-depth comparison of pre feeders and traditional sheet feeding methods, analyzing their effects on productivity, print quality, labor efficiency, and automation capability. It also explains why more manufacturers are choosing intelligent corrugated equipment—especially pre feeding solutions designed to support fully automatic lines like those developed by Giant.

Understanding the Role of Feeding Systems in Corrugated Production

Feeding is the first step in the workflow of a corrugated converting machine. Whether a line uses automatic or manual feeding determines how smoothly sheets enter the flexo unit, how well they align, and how consistently the entire system can sustain high-speed operation.

A fully automatic corrugated production line depends on uninterrupted sheet flow. Even minor inconsistencies—stack height variations, sheet slipping, or misalignment—can result in:

- print registration issues

- inaccurate slotting and die cutting

- machine stoppages

- increased waste

- reduced production speed

This is why feeding systems have become a primary focus in modernizing corrugated facilities.

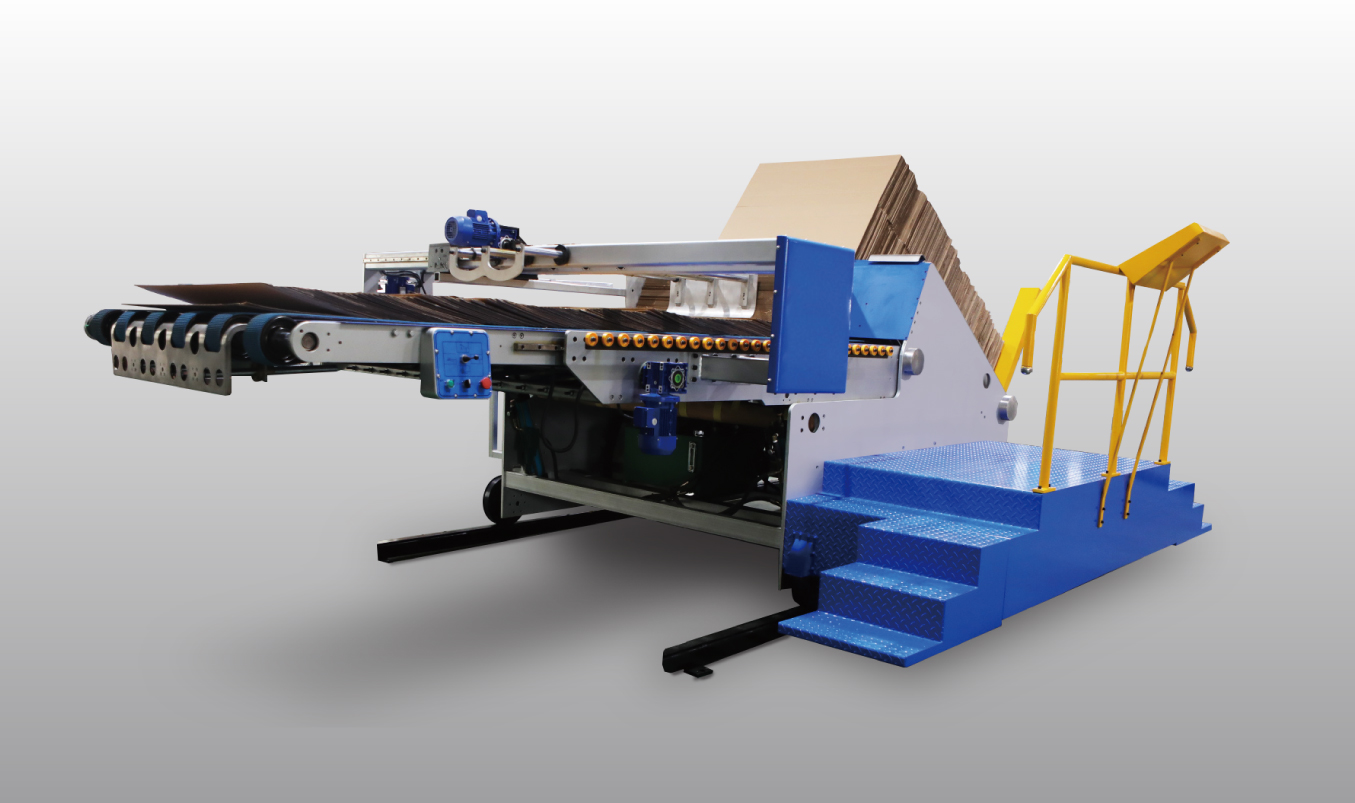

What Is a Pre Feeder and How Does It Work?

A pre feeder is an automated sheet-loading and feeding device placed before a flexo printer slotter die cutter machine. It is designed to supply sheets continuously, accurately, and at high speed—allowing the main machine to operate at its full rated capacity.

Core functions of a pre feeder include:

1. Automatic Lifting and Buffering of Sheet Stacks

The pre feeder lifts entire stacks to a precise height and automatically maintains the feeding level as sheets are consumed.

2. Controlled Sheet Separation and Alignment

Sheets are separated uniformly, aligned mechanically, and introduced into the machine at a consistent pace.

3. Synchronization With High-Speed Lines

The feeding rhythm matches the production speed of the flexo printer slotter, enabling high-throughput corrugated converting.

4. Stable and Continuous Flow

Because sheet loading is automated, stack changeovers are quick, and feeding interruptions are minimized.

5. Fully Automatic and Intelligent Control

Sensors monitor sheet position, speed, and pile height; PLC systems make real-time feeding adjustments.

In short, the pre feeder transforms feeding into a stable, automated, and intelligent process—ideal for high-speed packaging operations.

What Are Traditional Feeding Methods?

Traditional feeding includes manual feeding and semi-automatic feeding.

Manual Feeding

Operators manually lift sheets, align stacks, and push them toward the feed table. This method is labor heavy and dependent on operator experience.

Semi-Automatic Feeding

Mechanisms may assist in sheet transfer, but operators still handle stacking, leveling, and adjustment.

While these methods have lower initial cost, their limitations grow apparent as production speeds increase.

Common challenges:

- slower feeding speed

- inconsistent sheet delivery

- higher misalignment rates

- increased waste

- reliance on skilled labor

- fatigue-related performance drops

- frequent micro-stoppages affecting the entire line

Traditional feeding may still work for low-output factories, but it places a ceiling on production efficiency.

Pre Feeder vs Traditional Feeding: Detailed Performance Comparison

1. Production Speed and Throughput

A pre feeder supports the high-speed operation of modern corrugated converting lines, enabling sustained production speeds of 180–350 sheets/min. Because feeding is synchronized with machine cycles, the flexo unit can run continuously without unnecessary stops.

Traditional feeding rarely exceeds 60–120 sheets/min, and actual performance is often lower due to inconsistent operator control.

Result: Pre feeders unlock the true capacity of high-speed corrugated production lines.

2. Feeding Stability and Print Quality

High-speed flexo printer slotter die cutters require sheets to enter in perfect condition—flat, aligned, and stable. A pre feeder ensures uniform spacing and prevents skewing, which significantly improves print registration and die-cut accuracy.

Traditional feeding is more vulnerable to:

- warped sheet entry

- uneven feeding pressure

- skewed feeding angles

- height variations that affect print rollers

These issues directly affect color consistency, slot accuracy, and die-cut edge quality.

Result: Pre feeders deliver superior print and converting accuracy.

3. Labor Efficiency and Safety

A pre feeder eliminates the need for operators to repeatedly lift heavy corrugated stacks. Instead, they simply place full pallets near the device and supervise the process.

Benefits include:

- reduced physical strain

- fewer workplace injuries

- less operator fatigue

- one operator can manage multiple machines

Traditional feeding requires constant lifting, pushing, and manual alignment—making it labor-intensive and ergonomically risky.

Result: Pre feeders significantly reduce labor load and improve workplace safety.

4. Line Stability and Downtime Reduction

Pre feeders maintain constant sheet availability, which prevents:

- feeding jams

- misfeeds

- micro-downtime

- speed slowdowns

- re-start alignment issues

Traditional feeding often forces operators to compensate manually for sheet inconsistencies, leading to:

- irregular machine stops

- slower recovery time

- reduced OEE (Overall Equipment Efficiency)

Result: Pre feeders improve uptime and deliver more consistent production.

5. Waste Reduction and Material Utilization

Because pre feeders maintain precise sheet control, the risks of double-feeding, sheet scratching, corner damage, and misalignment are greatly reduced. This leads to lower waste—an important factor as corrugated materials continue to increase in cost.

Traditional feeding generates more scrap due to operator errors, inconsistent alignment, and misfeeds.

Result: Pre feeders reduce waste and increase material utilization.

Why Modern Corrugated Factories Are Upgrading to Intelligent Pre Feeders

Today's corrugated manufacturing environment demands:

- high-speed converting

- precise print accuracy

- reduced labor dependence

- seamless automation

- lower cost per box

- data-driven production

A pre feeder directly supports all of these objectives. More importantly, it is a necessary component for plants that plan to adopt fully automatic corrugated machinery, smart control systems, or Industry 4.0 production models.

A factory that upgrades its feeding system is not just improving one machine—it is strengthening the entire workflow.

Why Giant Pre Feeders Stand Out

Giant is a trusted manufacturer of Intelligent Fully Automatic Flexo Printer Slotter Die Cutter lines, and its pre feeders are specifically engineered to match the speed and precision of modern corrugated operations.

Key advantages of Giant's pre feeders:

- High-speed synchronization with flexo printing, slotting, and die cutting units

- Intelligent PLC control for automatic feeding adjustments

- Stable sheet transfer for long-format and high-volume corrugated sheets

- Reinforced mechanical structure for continuous 24/7 production

- Smooth integration with auto stackers and fully automatic production lines

- Reduced operator workload with minimal manual intervention

These capabilities make Giant's pre feeders ideal for carton plants upgrading to high-speed, fully automatic corrugated machinery.

Conclusion

In the past, traditional feeding methods were adequate for small-scale carton production. But as the corrugated industry shifts toward automation, higher volumes, and improved printing precision, traditional feeding has become a major limitation.

A pre feeder offers the automation, stability, accuracy, and speed that modern corrugated production lines demand. It supports better print registration, reduces waste, minimizes downtime, and ensures the flexo printer slotter die cutter runs at full capacity.

For manufacturers planning to modernize or scale their operations, the clear choice is a pre feeder—especially when integrated with intelligent converting equipment such as the solutions provided by Giant. It is not only a feeding device, but a strategic upgrade that directly improves productivity, cost efficiency, and output quality.