How Flexo Printer Slotter Die Cutter Machines Support High-Speed Carton Production?

In the competitive world of modern packaging, speed, accuracy, and flexibility are no longer optional—they are essential. Manufacturers in the corrugated box industry must meet increasing demands for high-quality printed cartons, shorter lead times, and mass customization. This is where flexo printer slotter die cutter machines prove to be game changers. These advanced systems allow packaging factories to maintain high production volumes without sacrificing print quality or structural precision.

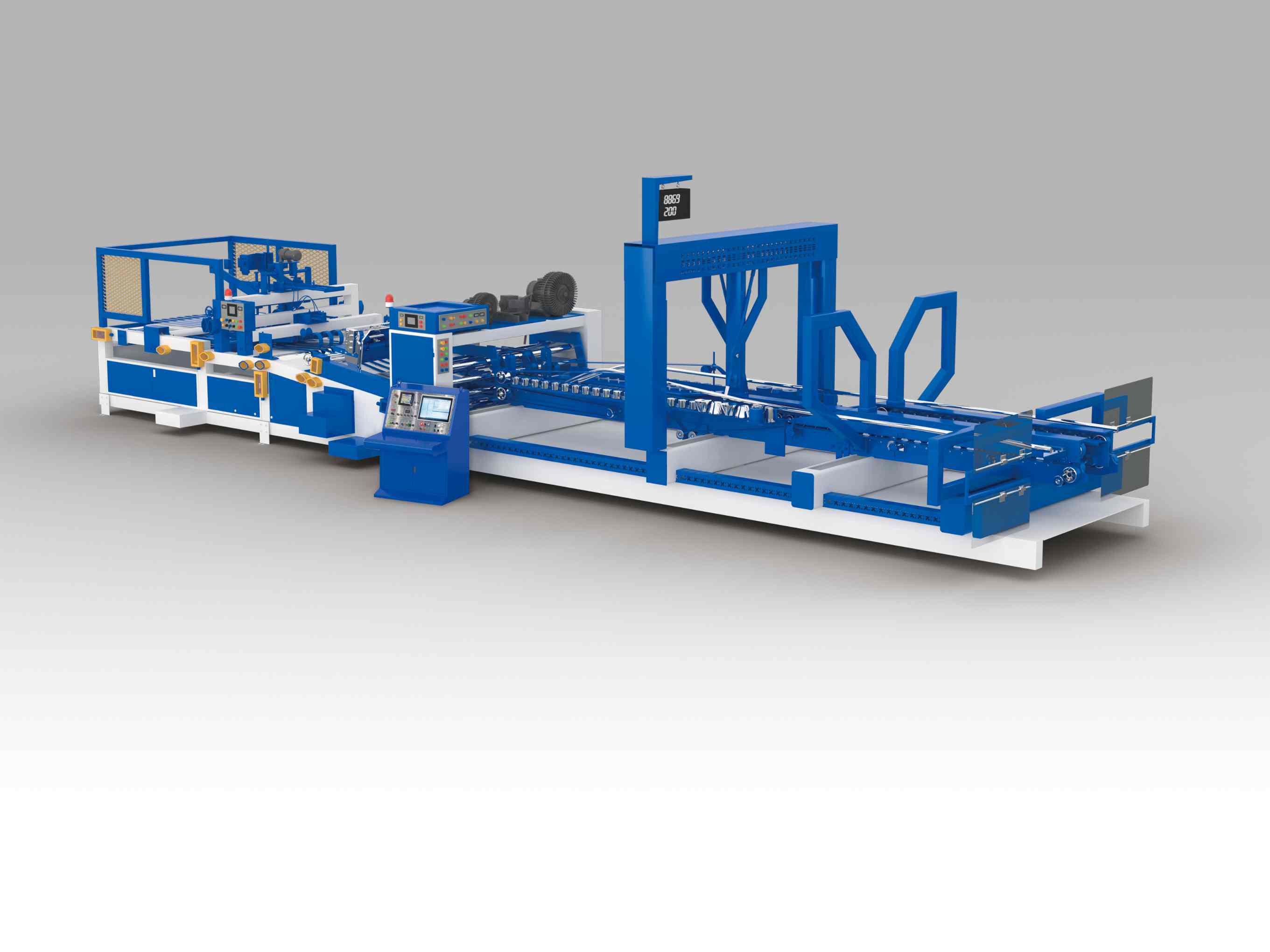

As a complete inline solution that integrates flexographic printing, slotting, scoring, and die cutting, this type of equipment is widely used in corrugated carton production, particularly for high-speed packaging lines. Let's explore how these machines support fast, efficient, and scalable box manufacturing—and why many global producers are now choosing reliable partners like Giant to stay ahead of the curve.

Understanding the Flexo Printer Slotter Die Cutter Machine

This machine combines multiple production processes into a single continuous operation. Corrugated sheets are fed into the system, printed using flexographic technology, then precisely slotted and die-cut before being delivered in stacks—ready for folding and gluing.

Such integration eliminates the need for separate machinery and reduces manual handling, which directly boosts efficiency. In modern setups, especially those that are fully automatic, speeds can exceed 300 sheets per minute. That kind of performance is critical for factories with high output requirements, especially in industries like e-commerce, food and beverage, and consumer goods packaging.

Key Features That Enable High-Speed Carton Manufacturing

One of the defining strengths of the flexo printer slotter die cutter machine lies in its ability to handle complex tasks quickly and accurately. While high speed is crucial, it must not come at the expense of quality or consistency. Several features contribute to both speed and performance:

- Servo-controlled registration systems: These ensure precise alignment of the print and die-cut, even at maximum speed.

- Auto-feeding and stacking systems: Reduce manual labor and enable continuous operation without interruption.

- Quick job changeover functions: Machine memory allows operators to switch between jobs in minutes, ideal for short runs and custom orders.

- Compatibility with various board grades: From lightweight E-flute to heavy-duty double-wall sheets, the system handles diverse material requirements.

These features allow the machine to function as the core of any high-speed corrugated box production line, reducing downtime and maximizing output.

The Role of Automation in Achieving Speed

In traditional box making, production speed was often limited by manual processes and frequent changeovers. Today's fully automatic flexo slotter die cutter machines are engineered to overcome these challenges. With features like touch-screen controls, digital setting storage, and real-time error detection, these machines reduce setup time dramatically.

For example, a factory switching between a small pizza box order and a large appliance carton can do so with minimal adjustment time. This flexibility supports just-in-time production, which is increasingly important in lean manufacturing environments.

Moreover, the integration of automatic anilox roll cleaning systems, print plate changing tools, and centralized lubrication further enhances operational efficiency. These functions minimize interruptions and extend the machine's service life—allowing packaging companies to run production lines at full capacity for longer periods.

Improving Quality at High Speed

While speed is crucial, consistent quality remains a top priority. High-speed operation can often lead to print misalignment, inaccurate slotting, or uneven die-cutting. However, the latest flexo printer slotter die cutter machines are built to counter these risks through

- High-resolution print heads that ensure sharp, vivid images even at top speeds.

- Precision cutting dies that maintain dimensional accuracy throughout long production runs.

- Digital tension control that manages board feed for uniform print and cut quality.

These technologies help maintain brand image and structural integrity—two critical aspects in retail and shipping environments where packaging presentation matters.

Flexo Slotter Machines for Diverse Industry Needs

Packaging manufacturers serving multiple industries benefit from the flexibility and speed of this machinery. For example, businesses producing boxes for fast-moving consumer goods (FMCG), electronics, or pharmaceuticals require not just rapid throughput but also tight control over customization and cleanliness.

The ability to handle complex print jobs, rapid format changes, and high-volume orders makes these machines essential for businesses that deal with seasonal spikes or operate across multiple markets. Whether producing display-ready retail boxes or heavy-duty transport cartons, flexo printer slotter die cutter machines are built to meet diverse packaging requirements.

Why Choose Giant as Your Equipment Partner?

If you're planning to scale up your carton production or replace outdated machinery, choosing a reliable flexo slotter die cutter machine supplier is critical. This is where Giant stands out as a trusted name in the packaging machinery industry.

Giant specializes in designing and manufacturing high-speed flexo printer slotter die cutter machines tailored to meet your specific production goals. Whether your factory focuses on large-scale bulk box production or short-run custom packaging, Giant offers:

- Durable, industrial-grade equipment with long operating life

- Customizable machine configurations for various box styles

- Expert support from design consultation to after-sales service

- Smart automation features that reduce labor and maximize output

Many packaging companies across Asia, Europe, and North America already trust Giant's machines to power their daily operations. With a focus on efficiency, precision, and adaptability, Giant helps clients achieve consistent, high-speed carton manufacturing performance.

Conclusion

In an era where speed, accuracy, and adaptability define success in packaging, flexo printer slotter die cutter machines play a central role. These machines not only boost production capacity but also ensure consistent quality, reduce waste, and allow seamless integration into fully automated lines.

From quick setup to smart job recall, from precise printing to accurate die cutting, every feature is designed to support high-speed operations. For manufacturers seeking a dependable, future-ready solution, partnering with a supplier like Giant offers the competitive edge needed to thrive in today's dynamic packaging market.

Frequently Asked Questions (FAQ)

1. What types of cartons can a flexo printer slotter die cutter machine produce?

These machines can produce a wide range of corrugated boxes, including regular slotted cartons (RSC), die-cut boxes, mailer boxes, and custom retail packaging. They are compatible with single-wall, double-wall, and triple-wall corrugated board, making them suitable for everything from lightweight e-commerce packaging to heavy-duty industrial cartons.

2. How fast can a high-speed flexo printer slotter die cutter machine operate?

High-speed models can reach processing speeds of 200 to 350 sheets per minute, depending on the sheet size, board thickness, and machine configuration. With automatic feeding and stacking systems, these machines are built for non-stop, large-volume carton production.

3. Is it possible to use different colors in printing with a flexo printer?

Yes. Most flexo printer slotter die cutter machines support multi-color printing, typically ranging from 2-color to 6-color setups. The use of water-based or UV inks ensures vibrant, fast-drying prints suitable for retail and branded packaging.

4. Can the machine be integrated with folder gluer or stitching lines?

Yes. Flexo printer slotter die cutter machines can be integrated into fully automated packaging lines, including folder-gluer units, stitching machines, and palletizing systems. This end-to-end solution ensures faster workflow and lower labor costs.

5. Why should I choose Giant as my equipment supplier?

Giant provides highly durable, customizable, and precision-engineered flexo printer slotter die cutter machines. With deep expertise in packaging automation and global service support, Giant ensures your investment delivers high returns, consistent performance, and low total cost of ownership.