The Ultimate Guide to Choosing the Right Flexographic Printing Machine for Your Business

In the fast-evolving world of packaging and label production, the flexographic printing machine has become an indispensable asset for businesses seeking efficiency, versatility, and top-tier print quality. As consumer demands shift and market competition intensifies, investing in the right flexo press is more critical than ever. This comprehensive guide will help you navigate the complex landscape of flexographic printing equipment, ensuring you make an informed decision that supports your business's growth and success. Along the way, you'll discover why Giant is the trusted partner for leading-edge flexographic solutions.

Understanding Flexographic Printing and Its Advantages

Flexographic printing—often referred to as flexo printing—is a rotary printing process that utilizes flexible relief plates to transfer ink onto a wide variety of substrates. This technology excels in high-speed, large-volume production and is renowned for its ability to print on materials ranging from paper and film to foil and nonwovens.

Key benefits of Flexographic Printing Machines include

High-Speed Production: Flexo presses can run at remarkable speeds, making them ideal for mass production of packaging, labels, and more.

Versatility: Capable of printing on diverse substrates, including flexible packaging, corrugated cardboard, plastic films, and metallic foils.

Cost-Effectiveness: Especially for long runs, flexographic printing delivers low per-unit costs and rapid job turnaround.

Eco-Friendly Options: Modern flexographic printing machines support water-based and UV-curable inks, reducing environmental impact and meeting sustainability goals.

Consistent Quality: With advancements in plate technology and ink management, flexo presses produce vibrant, high-resolution prints with excellent repeatability.

Assessing Your Business Needs

Before selecting a flexographic printing machine, it's crucial to analyze your specific production requirements. Consider the following factors:

Product Range: Are you focused on flexible packaging, self-adhesive labels, folding cartons, or corrugated boxes? Each application may require different press configurations.

Production Volume: High-volume operations benefit from robust, high-speed flexo presses, while smaller businesses may prioritize flexibility and ease of use.

Substrate Types: Ensure the flexo press can handle all materials you intend to print on, considering thickness, flexibility, and surface finish.

Print Quality Expectations: If your clients demand precise color matching and fine detail, invest in a machine with advanced registration and ink control systems.

Available Space: Evaluate your facility's layout and infrastructure to accommodate the press's size, power, and ventilation requirements.

Types of Flexographic Printing Machines

Choosing the right type of flexographic printing machine is essential for maximizing efficiency and meeting your production goals. The three main configurations are

Central Impression (CI) Flexo Press: This design features a central drum that holds all substrates in place, ensuring perfect registration and consistent print quality. CI flexo presses are ideal for flexible packaging and high-quality film printing.

Stack Type Flexographic Press: With individual print stations stacked vertically, this configuration offers flexibility in printing both sides of the substrate and is commonly used for labels and paperboard packaging.

In-Line Flexo Press: Designed for thicker substrates like corrugated cardboard, in-line flexo presses allow for the integration of additional processes such as die-cutting, laminating, and coating, streamlining production for folding cartons and corrugated boxes.

Key Features to Consider in a Flexographic Printing Machine

When evaluating different flexo printing machines, prioritize the following features to ensure optimal performance and long-term value:

1. Print Quality and Registration

Look for machines equipped with advanced plate mounting systems, precise tension control, and automated registration adjustment. These features guarantee sharp, vibrant prints and minimize waste due to misalignment.

2. Production Speed and Automation

Modern flexographic printing presses offer impressive speeds, but automation is equally important. Automated job changeovers, plate cleaning, and ink management systems reduce downtime and labor costs, boosting overall productivity.

3. Substrate Flexibility

A versatile flexo press should accommodate a wide range of substrates, enabling you to expand your product offerings and adapt to market changes. Check for adjustable web paths, drying systems, and ink compatibility.

4. Ink and Drying Systems

Evaluate the press's compatibility with water-based, solvent-based, and UV-curable inks. Efficient drying systems, such as infrared or hot air dryers, ensure rapid ink curing and prevent smudging or set-off.

5. Ease of Maintenance

Downtime can be costly in high-volume printing environments. Choose a flexographic printing machine with accessible components, intuitive controls, and readily available spare parts to streamline maintenance and repairs.

6. Total Cost of Ownership

Beyond the initial investment, consider ongoing expenses such as ink, plates, energy consumption, and maintenance. A slightly higher upfront cost for a reliable, efficient press often results in significant long-term savings.

Why Choose Giant as Your Flexographic Printing Machine Partner?

When it comes to Flexographic Printing Machines, the manufacturer you choose is just as important as the machine itself. Giant stands out for its commitment to quality, innovation, and customer satisfaction.

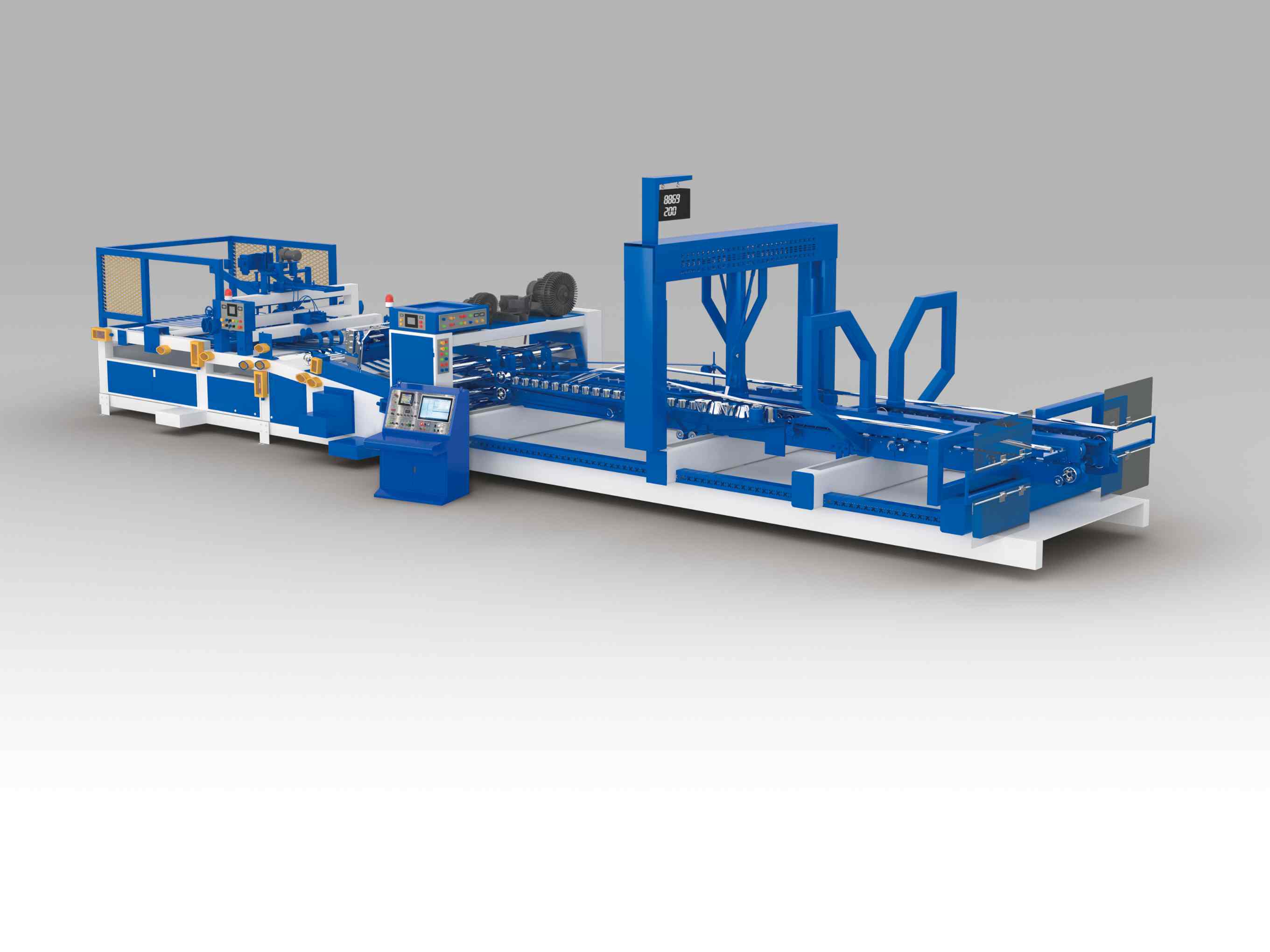

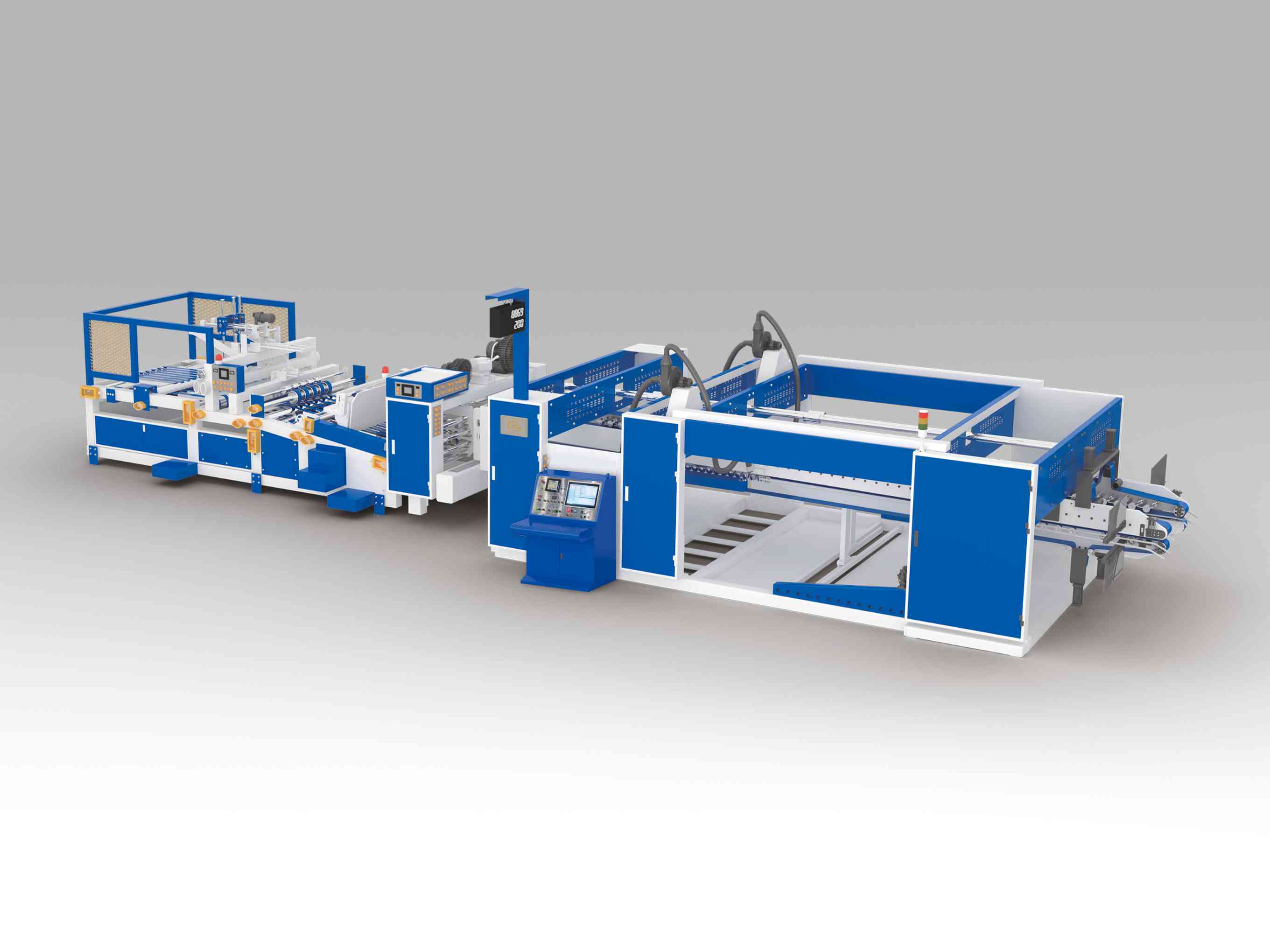

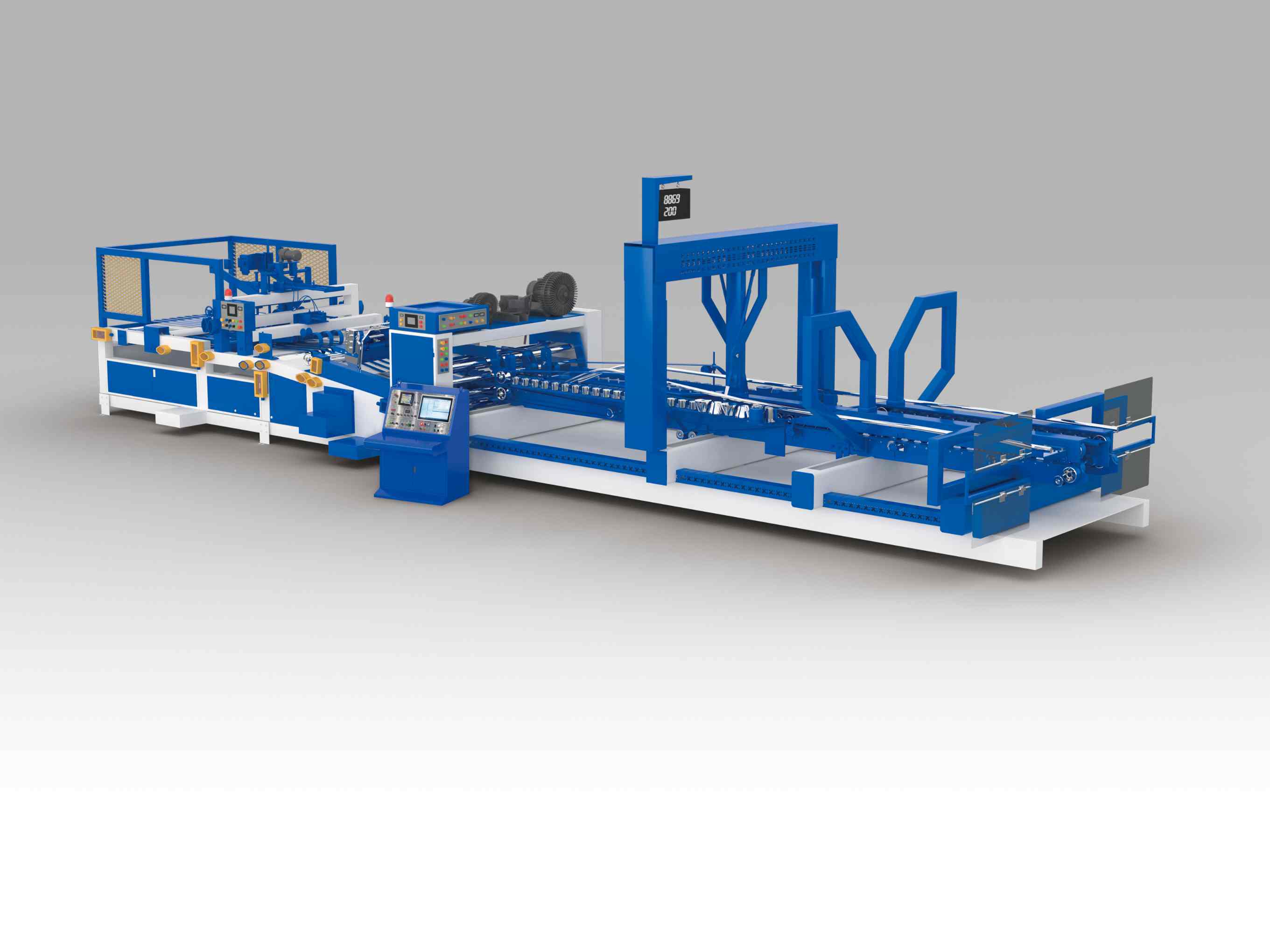

Tailored Solutions: Giant offers a range of flexo presses designed for various applications, from high-speed CI presses for flexible packaging to versatile stack and in-line models for labels and cartons.

Cutting-Edge Technology: With features like automated registration, energy-efficient drying, and intuitive digital interfaces, Giant's machines deliver superior print quality and operational efficiency.

Comprehensive Support: From initial consultation to installation, training, and ongoing technical assistance, Giant ensures a seamless experience and rapid problem resolution.

Sustainability Focus: Giant's presses are engineered for compatibility with eco-friendly inks and recyclable substrates, helping your business meet environmental standards and appeal to eco-conscious clients.

Proven Reliability: Businesses worldwide trust Giant for durable, low-maintenance flexographic printing equipment that stands the test of time.

Choosing Giant means gaining a partner dedicated to your business's long-term growth and success in the competitive world of flexographic printing.

Preparing for the Future of Flexographic Printing

As the packaging and labeling industries continue to evolve, staying ahead requires a proactive approach. Invest in a flexographic printing machine that not only meets your current needs but also positions your business for future opportunities. Look for modular designs, digital integration, and sustainability features that will keep your operations competitive for years to come.

Conclusion

Selecting the right flexographic printing machine is a strategic move that influences your business's efficiency, product quality, and market competitiveness. By carefully considering your production needs, print quality requirements, substrate range, and future growth plans, you can make an informed investment that delivers lasting value. With a trusted partner like Giant, you gain access to state-of-the-art technology, expert support, and a commitment to your ongoing success.

If you're ready to elevate your printing capabilities and achieve new levels of productivity, reach out to Giant today. Discover how our advanced flexo printing machines can help your business thrive in today's dynamic marketplace.