Flexographic vs Digital Printing: Which Is Best for Your Business?

In today's fast-evolving packaging and label industry, the choice between flexographic printing and digital printing is more important than ever. As businesses strive for efficiency, sustainability, and cost-effectiveness, understanding the strengths and limitations of each technology is crucial. This comprehensive guide explores both printing methods in depth, highlights the key factors influencing your decision, and demonstrates why choosing a Giant flexographic printing machine can give your business a significant competitive edge.

What is Flexographic Printing?

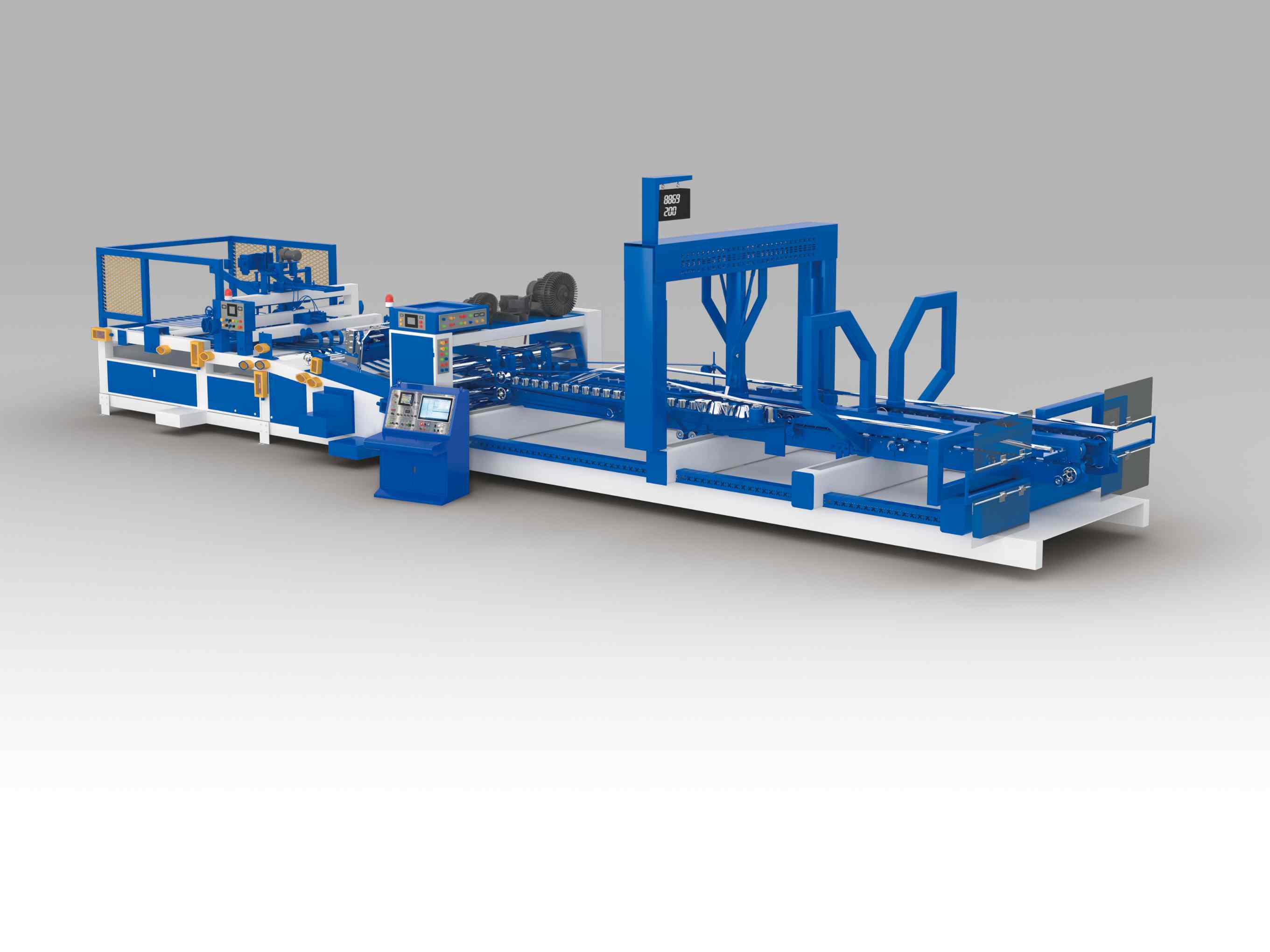

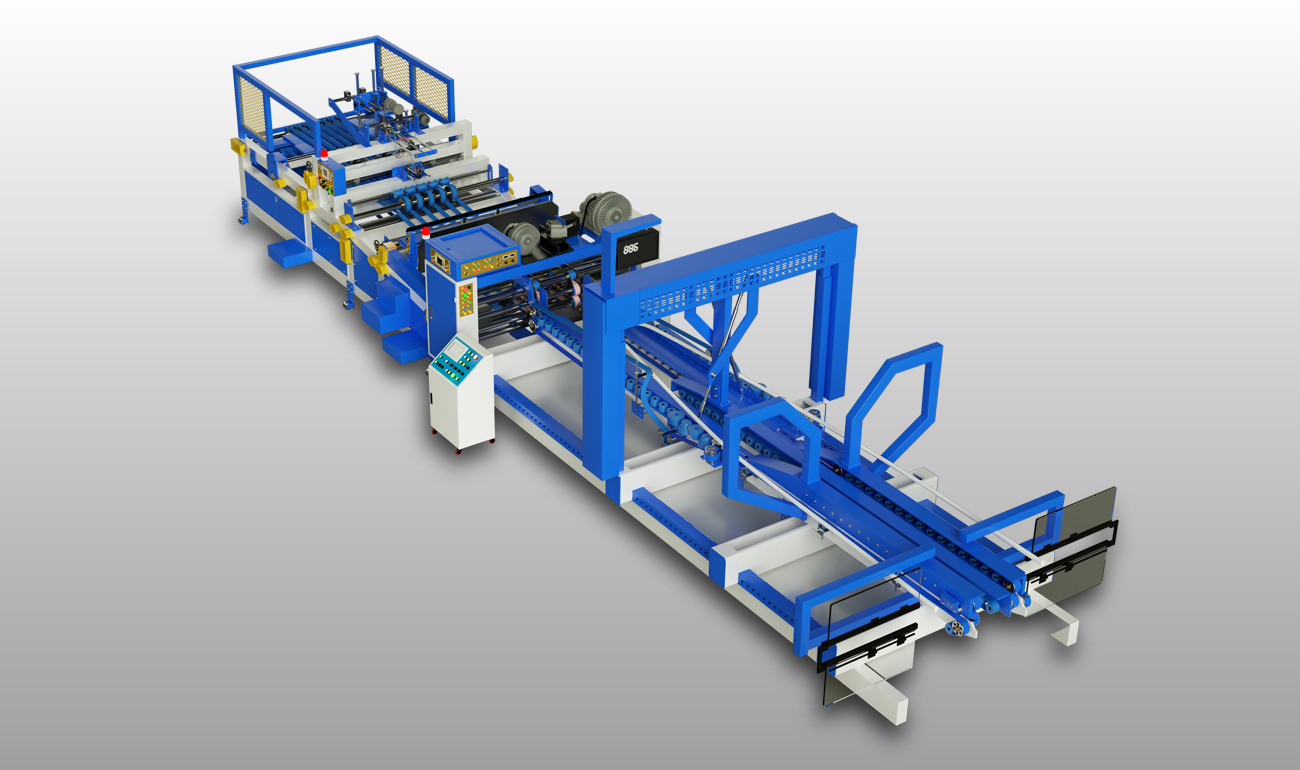

Flexographic printing (often called “flexo”) is a modern version of letterpress printing. It uses flexible photopolymer plates wrapped around rotating cylinders on a web press. These plates are inked and then pressed against the printing surface, transferring the image with remarkable precision. Flexographic printing is renowned for its versatility, high speed, and ability to handle a wide variety of substrates, including paper, plastic films, metallic foils, and even non-porous materials.

Key Advantages of Flexographic Printing

High-Speed Production: Flexo presses are built for speed, making them ideal for long print runs and large-scale packaging projects.

Material Versatility: Flexo can print on a broad range of substrates, from thin films to thick corrugated cardboard, giving manufacturers flexibility in product design.

Cost Efficiency for Large Runs: While initial setup costs (such as plate creation) are higher, the per-unit cost drops significantly as print volumes increase.

Eco-Friendly Options: Modern flexographic machines, like those from Giant, support water-based and UV-curable inks, reducing environmental impact and supporting sustainability goals.

Consistent Quality: Flexo technology delivers sharp, repeatable results, especially important for branding and regulatory compliance in packaging.

What is Digital Printing?

Digital printing eliminates the need for plates, using inkjet or laser technology to transfer images directly onto substrates. It has revolutionized short-run and customized printing, offering quick turnaround and design flexibility.

Key Advantages of Digital Printing

Short-Run Flexibility: Digital printing excels at producing small batches and prototypes, making it ideal for businesses needing frequent design changes.

Variable Data Printing: Each printed piece can be unique, supporting personalized packaging, barcodes, and regional customization.

Minimal Setup Time: Without the need for plates or lengthy setups, digital jobs can start almost instantly, reducing lead times.

Lower Initial Investment: For businesses with limited capital or low-volume needs, digital presses offer a lower barrier to entry.

Head-to-Head: Flexographic Printing vs. Digital Printing

When comparing flexographic printing and digital printing, several critical factors emerge:

1. Print Volume and Cost Efficiency

Flexographic printing is the clear winner for high-volume jobs. Dramatically lower per-unit costs offset the upfront investment in plates and setup as quantities rise. For example, packaging companies producing tens of thousands or millions of labels benefit from the speed and efficiency of flexo presses. Digital printing, while cost-effective for short runs, becomes expensive as volumes increase due to higher ink and maintenance costs.

2. Substrate Versatility

Flexographic presses are engineered to handle a vast array of substrates. Whether you need to print on flexible packaging films, rigid cartons, or specialty materials like metallic foils and biodegradable substrates, flexo offers unmatched adaptability. Digital presses, while improving, still face limitations with certain materials, especially when durability or special finishes are required.

3. Print Quality and Consistency

Modern flexographic machines, especially those from Giant, deliver exceptional print quality with consistent color reproduction and fine detail. Flexo's ability to maintain tight registration across long runs ensures every package or label looks identical. Digital printing offers impressive quality for short runs but may struggle with color consistency and durability on some substrates.

4. Customization and Turnaround

Digital printing shines when it comes to customization, versioning, and rapid prototyping. If your business requires frequent design changes, personalized packaging, or market testing, digital presses can deliver unique prints with minimal delay.

5. Sustainability and Environmental Impact

Sustainability is a growing priority in the printing industry. Flexographic printing has made significant strides with water-based inks, recyclable plates, and energy-efficient press designs. Giant's flexographic machines are at the forefront, offering advanced waste reduction systems and compatibility with eco-friendly materials. Digital printing reduces setup waste but may rely on specialty inks that are harder to recycle.

Why Choose Giant Flexographic Printing Machines?

Giant is a global leader in flexographic printing technology, known for innovation, reliability, and sustainability. Here's why Giant presses are trusted by top packaging manufacturers worldwide:

Advanced Automation: Giant flexo presses feature intelligent registration, automated plate mounting, and real-time quality monitoring, reducing labor costs and human error.

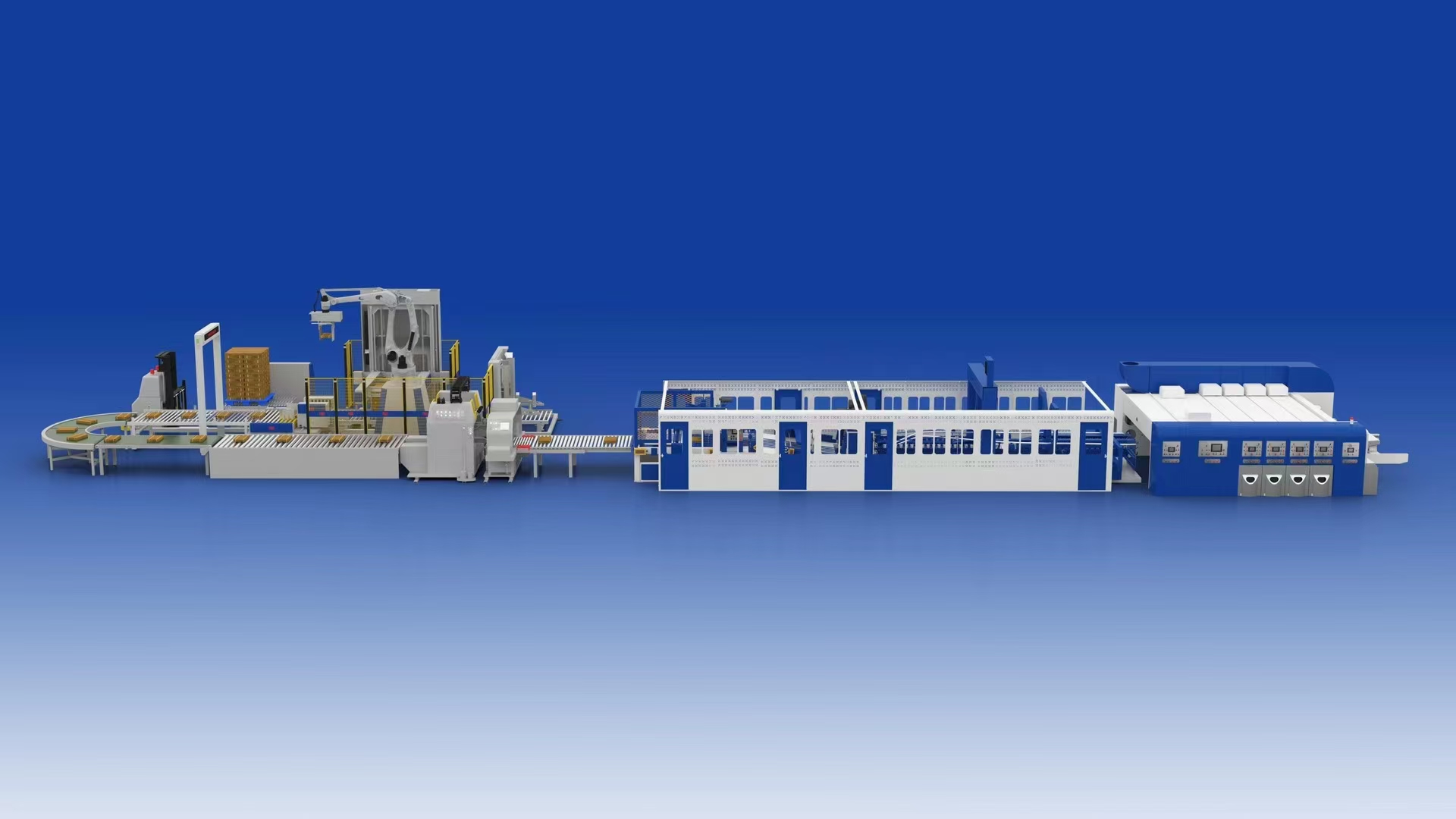

Hybrid Capabilities: Giant's hybrid flexo-digital solutions combine the speed and efficiency of flexo with the customization of digital, offering the best of both worlds for mid-sized runs.

Eco-Performance: Giant machines are engineered for low energy consumption, minimal waste, and compatibility with renewable materials, supporting your company's green initiatives.

Scalability: From compact presses for niche markets to wide-web giants for industrial-scale packaging, Giant offers solutions tailored to your growth.

Global Support: With a robust service network and comprehensive training, Giant ensures your presses deliver peak performance year after year.

Making the Right Choice for Your Business

When deciding between flexographic and digital printing, consider your current and future production needs. If your business demands high-volume, high-speed, and cost-effective printing across a variety of substrates, flexographic printing—especially with Giant's advanced presses—is the superior choice. For businesses focused on short runs, rapid prototyping, or personalized packaging, digital printing offers unmatched flexibility.

Conclusion

In summary, flexographic printing remains the gold standard for large-scale, versatile, and sustainable packaging production. With the latest innovations in automation, substrate handling, and environmental performance, Giant flexographic presses empower your business to achieve outstanding results—now and into the future. Invest in Giant, and you're investing in reliability, efficiency, and a greener tomorrow.

If you're ready to elevate your production capabilities and stay ahead of the competition, contact Giant today to learn more about our flexographic printing solutions and schedule a demonstration tailored to your unique needs.