Top Flexo Printer Slotter Die Cutter Machine Manufacturer in China

China has become the global center of corrugated packaging machinery manufacturing, especially for flexo printer slotter die cutter machines. As packaging demand increases in industries like e-commerce, food, and pizza boxes, carton plants are looking for reliable suppliers with strong engineering capabilities, competitive prices, and advanced automation technologies. This makes choosing the right manufacturer a critical investment decision.

This guide explains what buyers should expect from leading Chinese flexo printer slotter die cutter machine manufacturers, key technologies to look for, and why working with a trusted supplier like Giant ensures long-term productivity and profitability.

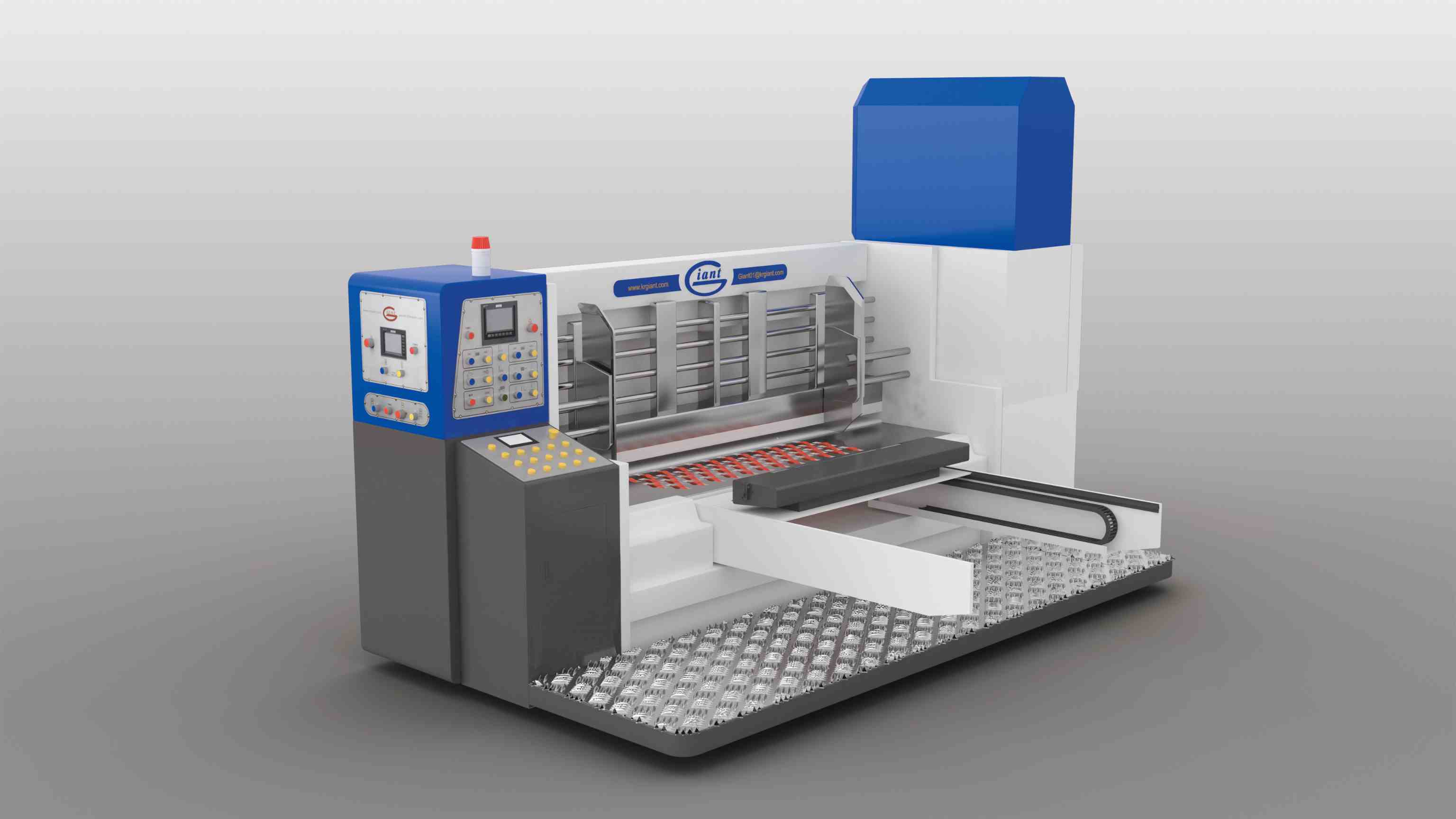

What Is a Flexo Printer Slotter Die Cutter Machine?

A flexo printer slotter die cutter machine is an inline corrugated packaging solution combining:

- Flexographic printing

- Slotting

- Rotary die cutting

- Folding and gluing (optional depending on configuration)

It transforms corrugated board sheets into finished boxes in a single streamlined workflow. This reduces manual handling, increases output, improves print accuracy, and cuts production costs.

Applications include:

- Regular slotted cartons (RSC)

- Pizza boxes

- Die-cut packaging

- Shelf-ready packaging

- Industrial shipping boxes

- Retail graphic packaging

As demand shifts toward faster turnaround and better color graphics, equipment selection becomes more strategic.

Why Choose Chinese Manufacturers?

China leads the corrugated machinery market for several strong reasons:

- Cost-effective production with high quality industrial standards

- Strong technological upgrades in automation and servo motion control

- Wide model selections for small to large box plants

- Faster delivery lead time compared to overseas suppliers

- Availability of spare parts and training support

- Experience in high-graphics flexo printing

Companies in China also offer professional customization to meet factory layout, board grades, printing needs, and output goals.

Key Features Top Manufacturers Should Provide

When choosing a supplier, focus on features that guarantee stable performance and low waste:

1. Advanced Flexo Printing System

- Water-based environmental inks

- Motorized or automatic ink supply

- Doctor blade chamber system

- Ceramic anilox rollers for sharper print results

This ensures vivid images for pizza boxes and brand-heavy corrugated packaging.

2. Servo-Driven Slotting and Die Cutting

- Precise slot positioning

- Clean die-cut edges

- Stable operation at high speed

Improving box consistency reduces post-processing adjustments.

3. Intelligent Control & Registration

- Touchscreen HMI

- Remote diagnostics

- Automatic register correction

This maximizes uptime and reduces operator workload.

4. Quick-Change Design

- Tool-less adjustments

- Fast order changeover

- Less downtime for short runs

Ideal for multi-SKU packaging producers.

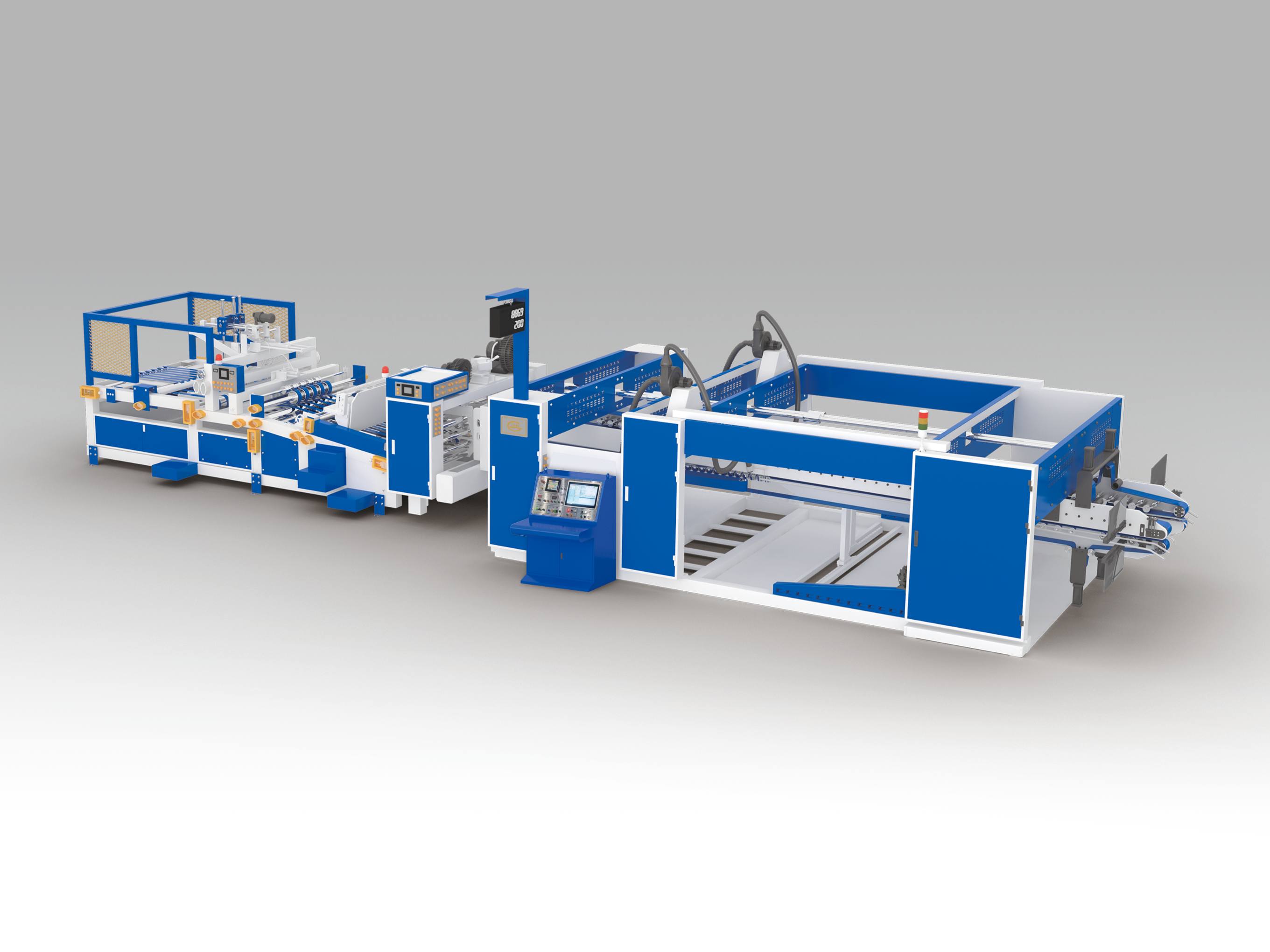

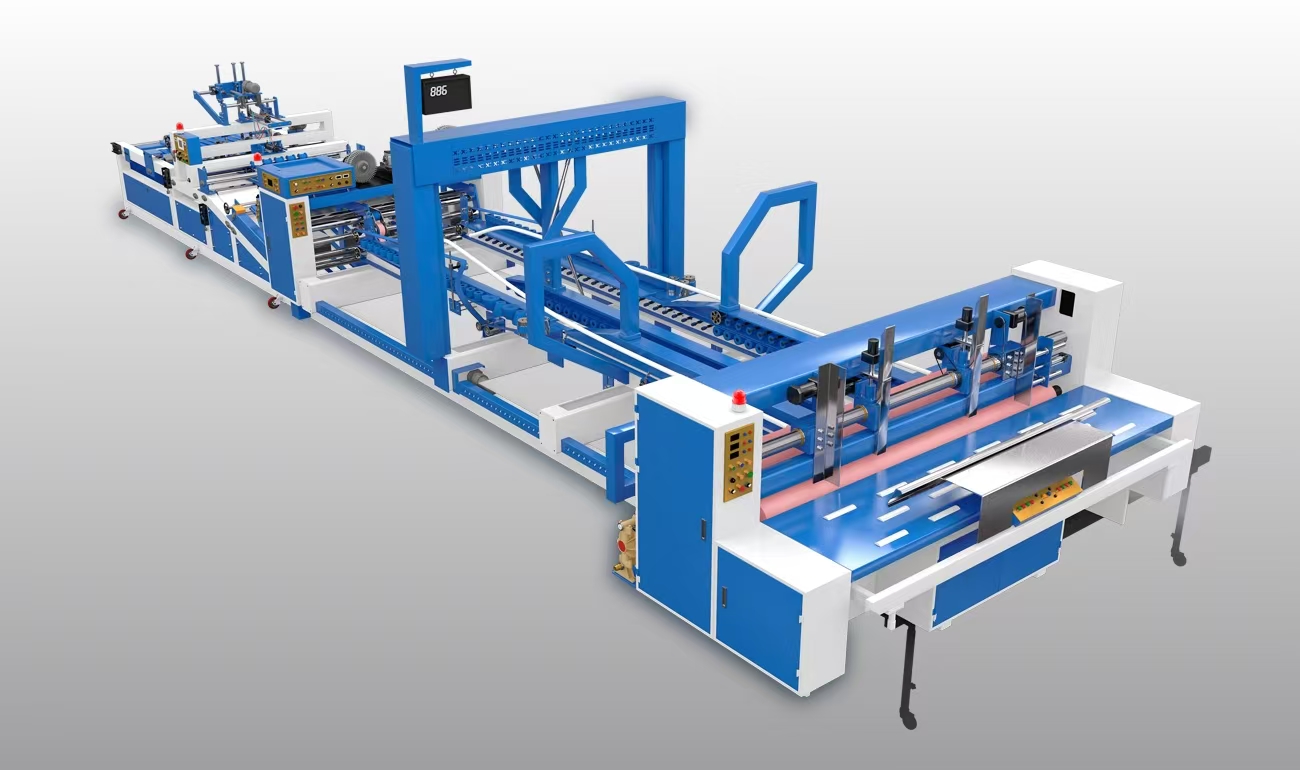

5. Integrated Inline Functions

Optional functions include:

- Inline folder gluer

- Stackers and logistics systems

- Vacuum transfer for warp-free transport

Complete automation supports just-in-time production strategies.

How to Evaluate a Flexo Printer Slotter Die Cutter Manufacturer in China

Technical Expertise

Choose manufacturers experienced in corrugated machinery engineering and servo systems, especially for high-speed production lines.

Manufacturing Strength

Modern machining centers, stringent quality testing, and assembly precision determine long-term reliability.

Project Experience

Prefer suppliers with verified installations in:

- Pizza box factories

- Export-oriented corrugated plants

- High-graphics printing markets

After-Sales Support

Key factors include:

- Installation and operator training

- Wear-part supply logistics

- 24/7 remote technical assistance

Compliance and Certifications

Look for CE, ISO industrial safety compliance, and food-packaging ink safety awareness.

Why Giant Stands Out as a Leading Manufacturer in China

As a specialized supplier of flexo printing and converting equipment for corrugated packaging, Giant delivers:

Strong Focus on Carton and Pizza Box Production

Our machines are engineered for excellent performance with corrugated substrates and food-grade packaging. Users benefit from reduced ink consumption, consistent color accuracy, and high print registration.

Custom Machine Solutions

Giant offers various models including:

- Flexo printer slotter die cutter machine

- Corrugated bottom printing machine

- Folder gluer integration systems

Whether for small-batch pizza box producers or large carton factories, we provide tailored specifications to match capacity goals.

Servo Automation and Smart Controls

Our equipment supports:

- High-speed production

- Quick job changeover

- Automated zero-defect setup features

This boosts efficiency and reduces operator skill dependence.

Global Customer Support

With successful installations across multiple countries, Giant provides professional technical service and training to ensure smooth operation.

Competitive Pricing with High ROI

We help box factories upgrade automation and reduce waste while maintaining affordable investment levels.

Purchasing Tips for Overseas Buyers

- Request complete machine layouts and factory workflow design

- Confirm corrugated board grade compatibility

- Review printing resolution and anilox specifications

- Ask for test runs with your printed artwork

- Compare operational data such as speed, waste rate, and downtime

- Choose manufacturers with clear after-sales agreements

A good partner not only sells machinery but empowers your growth.

Conclusion

Selecting a top flexo printer slotter die cutter machine manufacturer in China is essential for optimizing corrugated box production. With strong technical expertise, automation capabilities, and global service, Giant stands as a reliable partner for carton factories and pizza box producers seeking improved print quality, faster throughput, and reduced operational costs.

If you want your packaging line to stay competitive in today's high-demand market, investing in a high-performance flexographic converting machine from Giant will help you succeed for years to come.