Why Corrugated Slotter Machines Are Essential in Packaging Production

In today's fast-paced packaging industry, corrugated cartons remain one of the most widely used solutions for shipping, storage, and product display. From pizza boxes to e-commerce cartons and retail packaging, corrugated boxes provide strength, versatility, and cost efficiency. But behind every well-made box lies advanced machinery that ensures precision and productivity. Among these, the corrugated slotter machine plays a fundamental role.

A corrugated slotter machine is designed to cut slots, crease lines, and sometimes trim corners, turning a flat corrugated sheet into a foldable, functional carton. Without slotting, boxes cannot be assembled correctly, making this step essential in packaging production.

This article explains why corrugated slotter machines are indispensable for manufacturers, their role in the production process, and how investing in advanced slotter technology can benefit packaging companies worldwide.

What Is a Corrugated Slotter Machine?

A corrugated slotter machine is a piece of equipment used in the carton manufacturing process to cut slots and crease lines into corrugated board. These slots define the folding flaps of the carton, allowing the box to be assembled into its final shape.

Key Functions of a Slotter Machine

Slotting: Cuts straight openings in the corrugated sheet to form flaps.

Creasing: Creates fold lines for accurate carton assembly.

Corner Cutting: Removes unnecessary board edges for clean box formation.

Trimming: Adjusts board dimensions to ensure uniform size.

Slotter machines are often combined with flexographic printing machines to form printer slotter systems, enabling printing and slotting in one streamlined process.

The Role of Slotter Machines in Packaging Production

1. Structural Integrity of Boxes

Without precise slots and creases, a carton cannot fold properly. The slotter ensures the correct structure, strength, and load-bearing capacity of packaging.

2. High-Speed Manufacturing

Modern slotter machines are fully automated, capable of handling thousands of sheets per hour. This makes them essential for large-scale packaging production such as pizza box factories and e-commerce warehouses.

3. Consistency and Accuracy

Manual slotting leads to uneven folds and waste. Automated slotter machines guarantee uniform slots and creases, ensuring every carton has the same quality.

4. Compatibility with Die Cutting Machines

While die cutting machines customize boxes with handles, windows, or branding shapes, slotters prepare the basic structure. Both machines complement each other in the production line.

Benefits of Corrugated Slotter Machines

Enhanced Efficiency

Slotter machines reduce manual labor and speed up carton assembly, allowing manufacturers to meet tight deadlines.

Cost Reduction

By minimizing waste and errors, slotter machines lower production costs and improve profitability.

Wide Application

They are suitable for producing shipping cartons, pizza boxes, takeaway packaging, logistics boxes, and retail display cartons.

Integration with Flexo Printing

Many modern machines combine flexographic printing, slotting, and die cutting in a single system. This integration helps companies streamline operations and improve packaging quality.

Applications in Different Industries

Food Packaging: Pizza boxes, bakery cartons, and takeaway packaging.

E-commerce: Durable shipping cartons for online retailers.

Logistics: Heavy-duty corrugated boxes for transportation.

Retail: Branded cartons with high-quality printing and slotting.

Electronics & Fragile Goods: Custom-sized cartons for product protection.

Why Packaging Companies Invest in Slotter Machines

Scalability – The demand for corrugated cartons is growing rapidly with e-commerce expansion. Slotter machines allow packaging suppliers to scale up.

Quality Assurance – Automated slotters ensure neat, accurate folding lines that improve packaging appearance and durability.

Customization – Advanced slotters support flexible box sizes, catering to diverse packaging requirements.

Competitive Advantage – Faster production with lower costs helps manufacturers stay competitive in the global market.

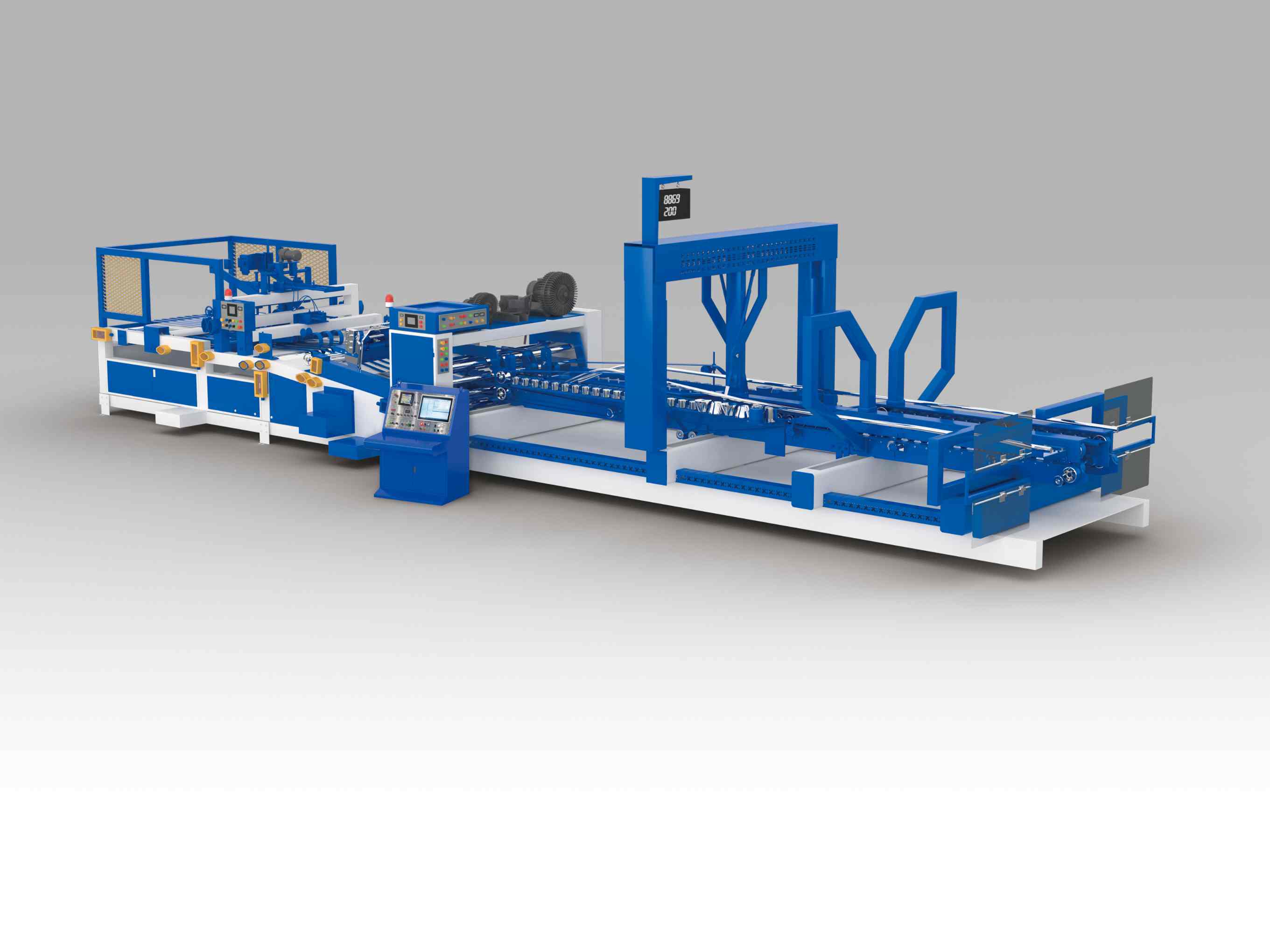

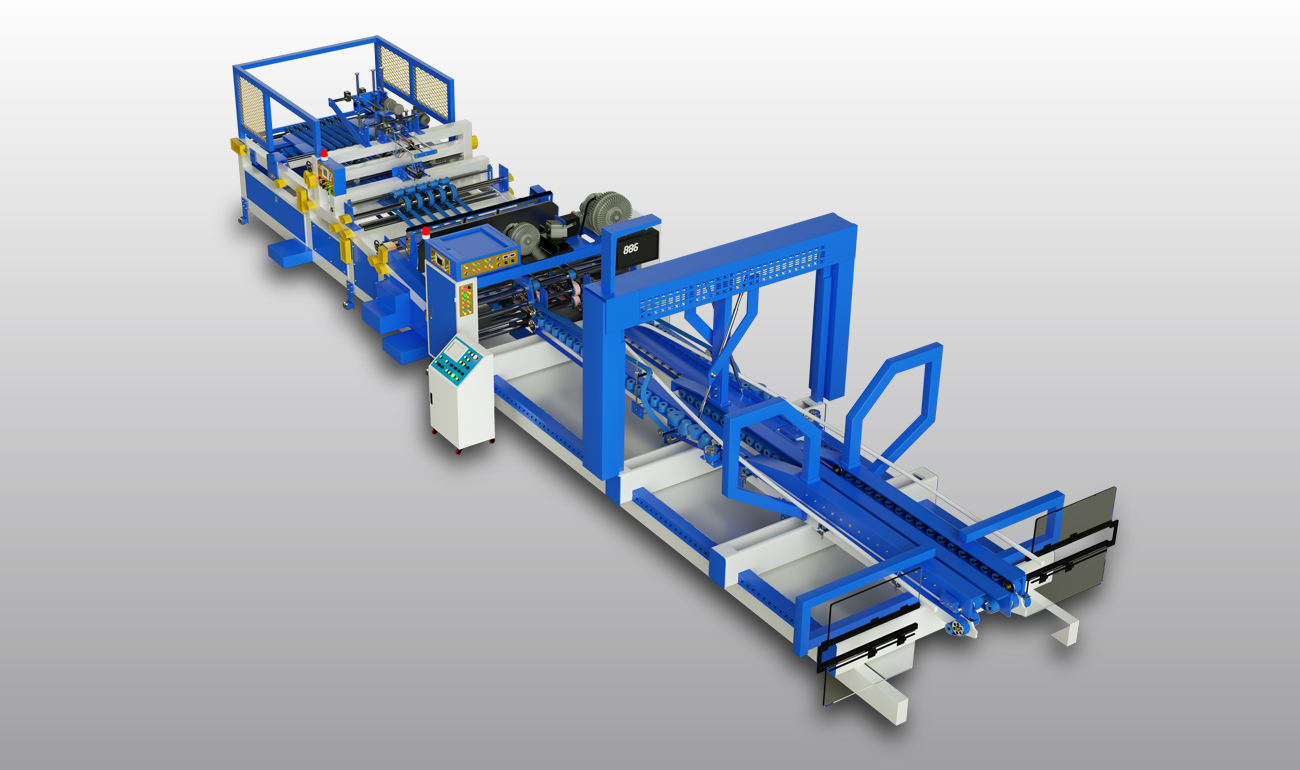

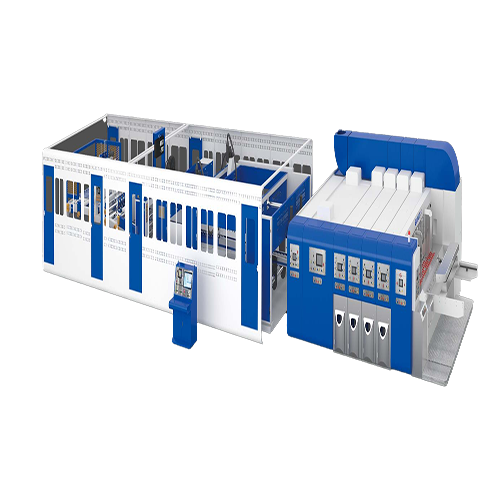

Giant's Corrugated Slotter Machine Solutions

At Giant, we provide high-performance corrugated slotter machines and flexographic printing slotter die cutters that meet the needs of packaging manufacturers worldwide.

Our machines are widely used in:

- Pizza box manufacturing plants

- Carton factories for logistics and retail packaging

- E-commerce packaging suppliers

By combining efficiency, durability, and precision, Giant's slotter machines help businesses improve production capacity, reduce costs, and deliver high-quality cartons that meet customer expectations.

The Future of Slotter Machines in Packaging Production

The packaging industry is evolving rapidly. Slotter machines are moving toward:

- Automation and AI-driven controls for better precision.

- Eco-friendly production with recyclable materials.

- Integration with digital printing for faster branding solutions.

- Smart maintenance systems to minimize downtime.

Investing in modern slotter technology ensures packaging manufacturers remain competitive in this growing industry.

Conclusion

Corrugated slotter machines are not just an accessory in carton manufacturing—they are a cornerstone of packaging production. By providing precision, speed, and structural accuracy, slotters make it possible to produce millions of cartons daily for industries worldwide.

For companies looking to improve efficiency and quality, slotter machines from Giant offer the perfect solution. With advanced technology, integrated printing options, and reliable performance, Giant helps packaging manufacturers achieve higher productivity and long-term success.