Corrugated Box Manufacturing: Role of Slotter and Die Cutting Machines

Corrugated box manufacturing is the backbone of the packaging industry, especially for cartons, shipping boxes, pizza boxes, and e-commerce packaging. With the global demand for sustainable and cost-effective packaging solutions, manufacturers rely on advanced machinery to ensure high efficiency, precision, and durability. Among the most crucial machines in the production line are the slotter machine and the die cutting machine. These two play a vital role in shaping, cutting, and finishing corrugated boards into fully functional cartons.

In this article, we will explore how corrugated slotter machines and die cutting machines contribute to carton production, their importance in modern packaging, and how choosing the right equipment can help manufacturers reduce costs and improve quality.

The Basics of Corrugated Box Manufacturing

Corrugated box production involves several stages, starting from raw paperboard to the final packaging product. The main process includes:

- Corrugating: Craft paper is shaped into fluted layers, giving the box its strength.

- Printing: Logos, brand details, and graphics are added using flexographic printing machines.

- Slotting: Slots or creases are cut into the board to create foldable flaps.

- Die Cutting: Customized shapes, handles, and windows are cut for specific packaging needs.

- Folding & Gluing: The box is assembled into its final form, ready for shipping or storage.

Among these steps, slotting and die cutting are essential in transforming a plain corrugated sheet into a usable, functional packaging box.

What Is a Slotter Machine?

A corrugated slotter machine is used to cut slots and crease lines into corrugated sheets. These slots allow the box to be folded into shape, forming the flaps on the top and bottom.

Key Functions of Slotter Machines

- Creasing: Ensures accurate fold lines for neat box assembly.

- Slotting: Cuts precise slots for flaps and openings.

- Corner Cutting: Removes unwanted edges to ensure perfect box shapes.

Benefits of Using Slotter Machines

- High efficiency – capable of handling large-scale carton production.

- Accuracy – delivers consistent slotting, reducing waste.

- Flexibility – supports a wide range of corrugated box sizes.

- Cost-effectiveness – minimizes manual labor and errors.

Modern slotters often integrate with flexo printing machines for printer slotter solutions, combining printing and slotting into one seamless process.

What Is a Die Cutting Machine?

A die cutting machine for corrugated boxes is designed to cut specific shapes, designs, or patterns. Unlike slotters, which produce straight slots and creases, die cutters allow for creative and customized packaging.

Types of Die Cutting Machines

- Flatbed Die Cutter: Best for thick corrugated boards and large runs.

- Rotary Die Cutter: Ideal for high-speed, continuous cutting in packaging plants.

Functions of Die Cutting Machines

- Cutting custom windows for product display.

- Shaping pizza boxes, takeaway boxes, or branded cartons.

- Punching out handles or ventilation holes.

- Creating unique folding designs for marketing appeal.

Advantages of Die Cutting in Carton Production

- Customization: Enables branding and differentiation.

- High Precision: Produces detailed cuts and shapes.

- Versatility: Works with both corrugated and cardboard sheets.

- Market Value: Enhances the look and feel of packaging, improving consumer experience.

Slotter vs. Die Cutting Machines: Their Role in Manufacturing

Both slotter machines and die cutting machines are crucial, but they serve different purposes in corrugated carton manufacturing:

- Slotter Machine: Handles structural functions, ensuring the box can be folded and assembled properly.

- Die Cutting Machine: Focuses on aesthetics and customization, giving boxes unique shapes and branding.

Together, they complete the transformation of plain corrugated sheets into functional, branded packaging solutions.

Applications of Slotter and Die Cutting Machines

These machines are widely used in various industries:

- Pizza Box Manufacturing – producing high-volume, food-grade boxes.

- E-commerce Packaging – durable shipping boxes with branding.

- Retail Cartons – printed, slotted, and die-cut boxes for product packaging.

- Logistics & Storage Boxes – sturdy corrugated cartons for bulk handling.

The Role of Flexographic Printing in Corrugated Boxes

While slotters and die cutters shape the carton, flexographic printing machines provide the final touch with high-quality graphics and logos. The combination of flexo printer slotter die cutter machines has become the standard in packaging plants, enabling manufacturers to complete printing, slotting, and die cutting in one line.

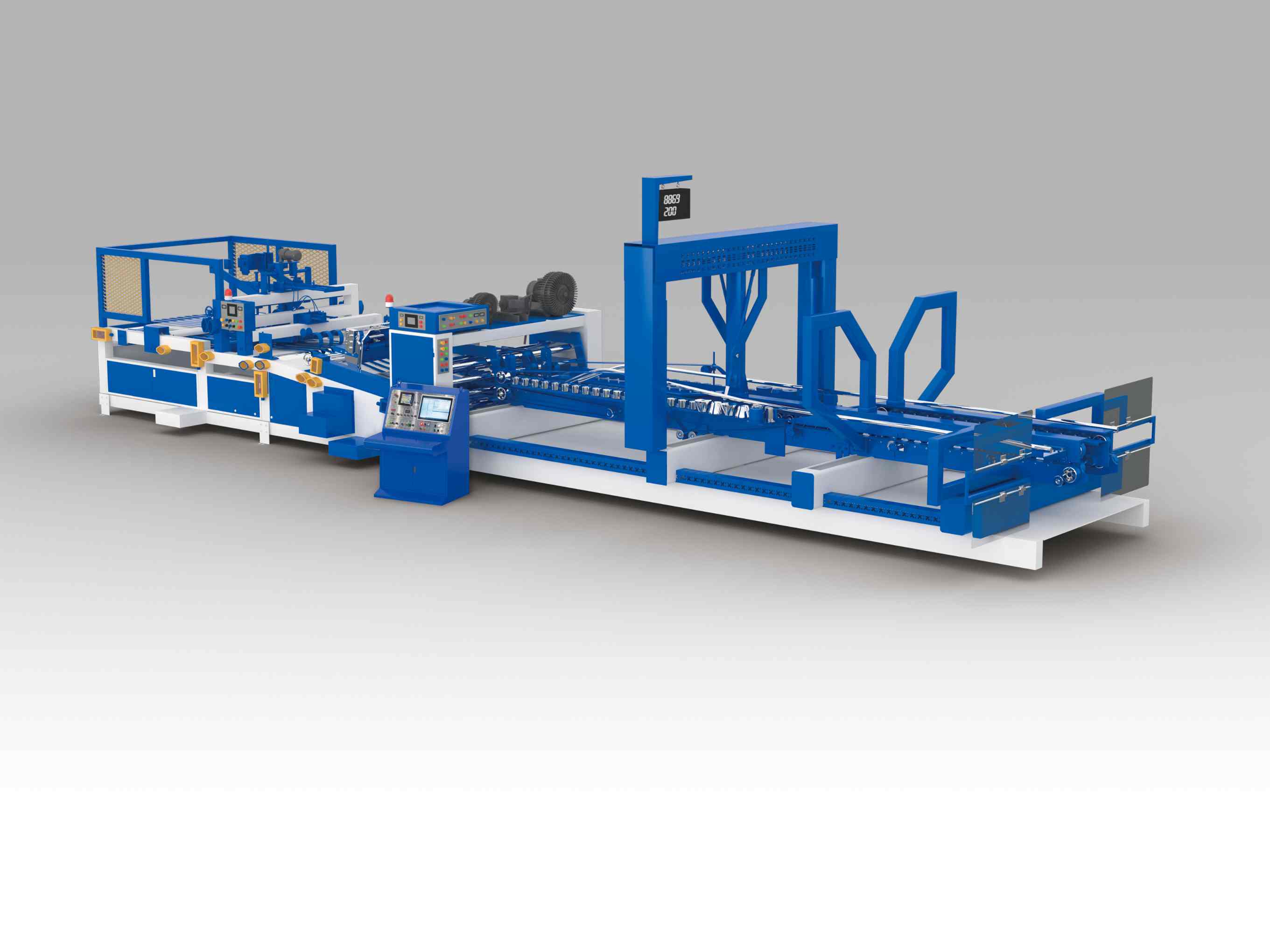

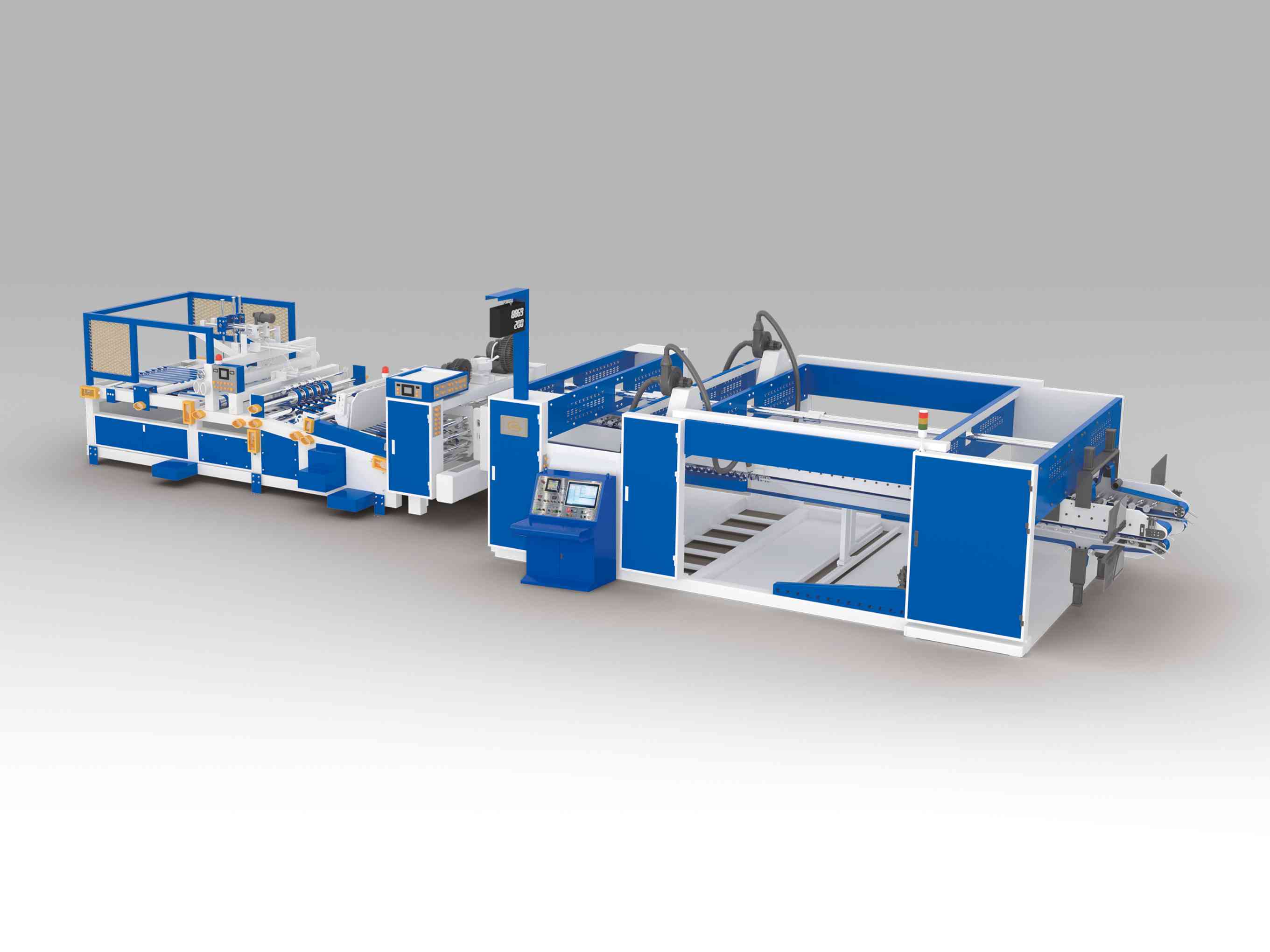

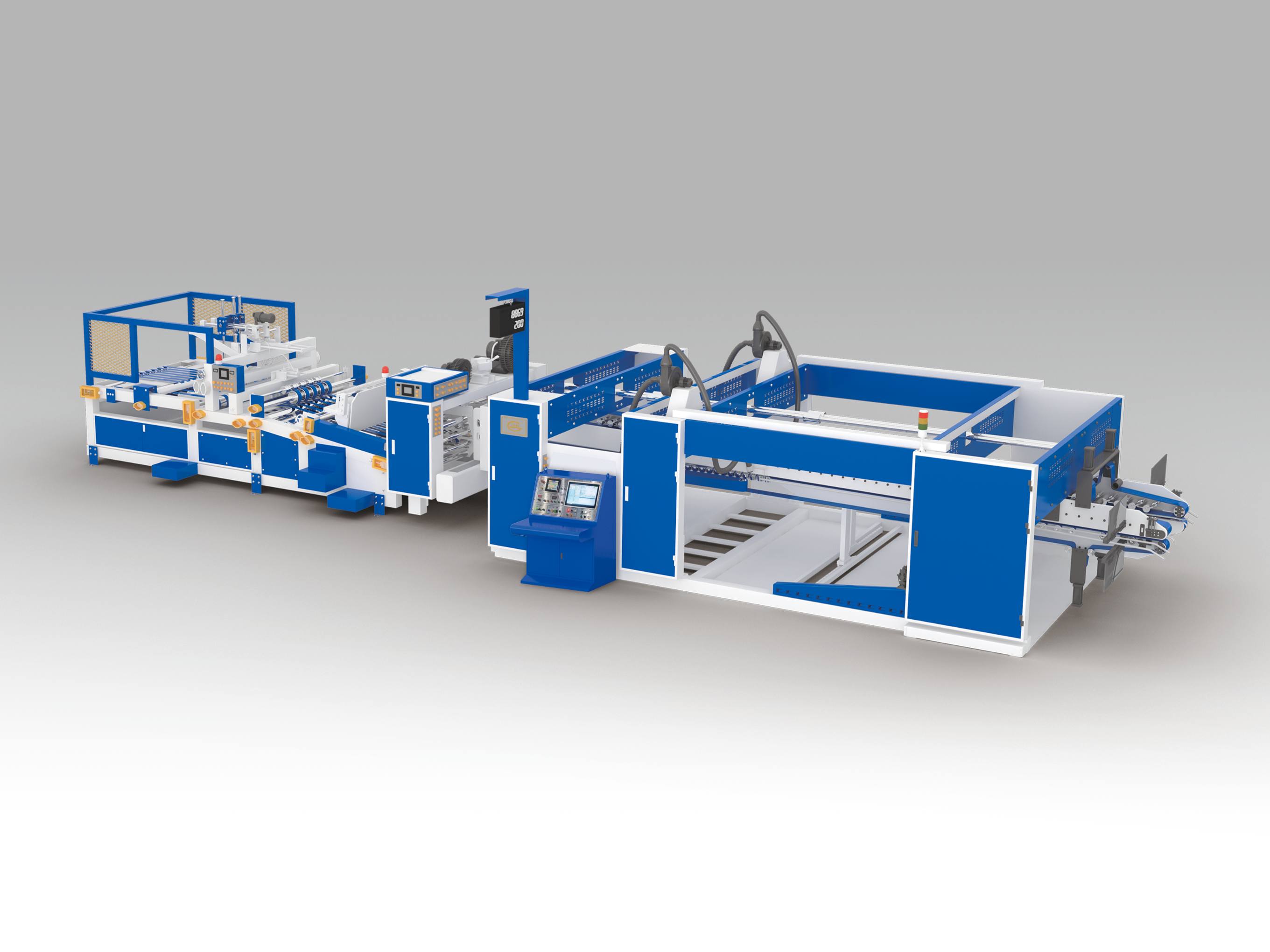

At Giant, we specialize in flexographic printing machines and corrugated slotter machines that deliver precision, durability, and efficiency for carton manufacturers. Our equipment is widely used in pizza box factories, corrugated box plants, and packaging suppliers looking for cost-effective production solutions.

Why Choose the Right Machinery?

Investing in the right slotter and die cutting machines brings multiple benefits:

- Improved productivity – faster turnaround with automated systems.

- Enhanced quality – consistent slots, creases, and cuts for professional packaging.

- Reduced waste – precision machinery minimizes material loss.

- Brand advantage – die-cut designs and flexo printing enhance visibility.

Manufacturers who adopt advanced flexo slotter and die cutting technology are better positioned to meet the growing demand for sustainable, attractive, and cost-effective corrugated packaging.

Future Trends in Corrugated Box Manufacturing

The future of carton production is moving toward:

- Automation – integrated flexo printer slotter die cutter lines.

- Sustainability – eco-friendly inks and recyclable corrugated materials.

- Customization – digital-assisted die cutting for unique packaging.

- Smart packaging – QR codes, traceability, and branding integration.

Conclusion

The success of corrugated box manufacturing depends heavily on the efficiency of slotter machines and die cutting machines. Together, they shape, cut, and customize corrugated sheets into strong, reliable, and attractive cartons for industries worldwide.

By investing in modern, high-performance equipment such as the flexo printer slotter die cutter solutions offered by Giant, packaging companies can improve productivity, reduce costs, and deliver packaging that meets the demands of today's competitive market.