Key Factors to Consider When Choosing a Flexo Printer Slotter Die Cutter for Your Packaging Line

Selecting a Flexo Printer Slotter Die-Cutter for your packaging line is one of the most consequential decisions a corrugated packaging manufacturer will make. The right equipment not only determines your production efficiency and product consistency but also shapes your ability to adapt to changing customer demands and market trends. In a landscape where clients expect rapid turnaround, high-quality printing, and custom box designs, investing in a machine that aligns with your business goals is essential. This article will walk you through the critical factors to consider, offer practical advice for balancing flexibility and cost, and explain why choosing Giant as your machinery partner can help you achieve sustainable growth and operational excellence.

The Role of Flexo Printer Slotter Die-Cutter in Modern Packaging

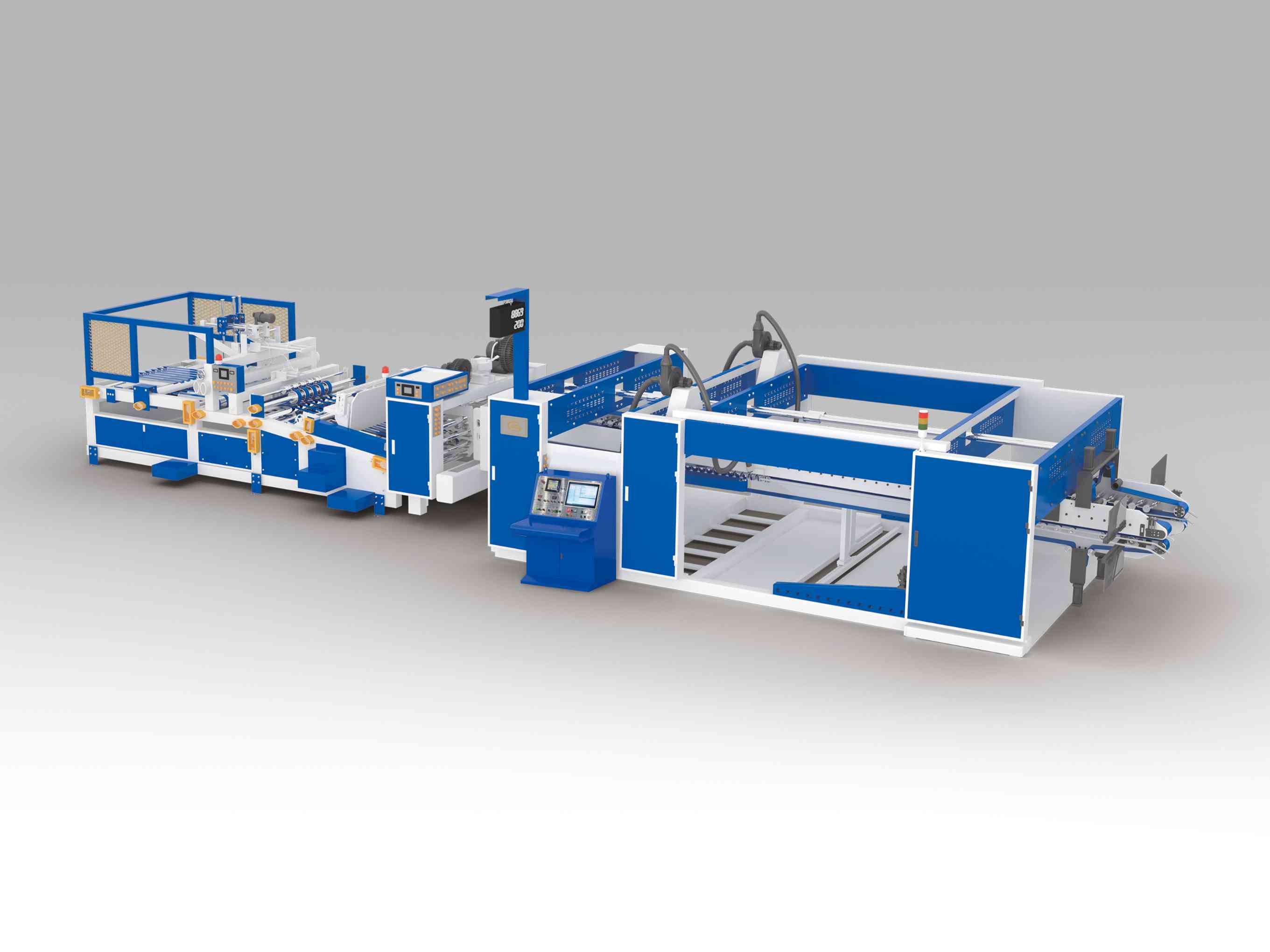

The flexo printer slotter die-cutter, also known as a flexographic printing machine, carton box printing machine, or corrugated box making machine, is the heart of any modern corrugated packaging operation. This equipment integrates high-speed printing, precise slotting, and customizable die-cutting into a single streamlined process. For manufacturers, this means the ability to efficiently produce a wide range of box types—from simple shipping cartons to complex retail packaging—while maintaining consistent quality and minimizing manual intervention.

Key Factors to Consider When Choosing a Flexo Printer Slotter Die-Cutter

1. Production Capacity and Speed

Production volume and speed should be the first consideration. If your business handles large orders or frequent design changes, you need a machine that can keep pace without sacrificing quality. High-speed machines equipped with automatic feeding, rapid plate and die changes, and intelligent control systems enable you to process hundreds of sheets per minute. This is crucial for meeting tight deadlines and maintaining a competitive edge.

- Evaluate maximum and minimum sheet sizes the machine can handle.

- Consider the speed of order changeover and plate replacement.

- Look for systems with quick setup and minimal downtime.

2. Print Quality and Registration Accuracy

In the packaging industry, print quality is a non-negotiable standard. Advanced flexo printing machines utilize high-precision anilox rollers and servo-driven print units to deliver sharp, vibrant images and consistent color registration. For businesses targeting premium clients or retail-ready packaging, superior print fidelity is essential.

- Assess the number of printing colors supported.

- Check for automated registration correction systems.

- Ensure compatibility with various substrates, including corrugated board and cardboard.

3. Die-Cutting and Slotting Flexibility

Your ability to offer diverse box designs depends on the die-cutting and slotting capabilities of your equipment. Rotary die-cutters and precision slotters allow for intricate shapes, custom flaps, and a variety of box styles. The flexibility to switch between different flute types and board thicknesses is critical for responding to market trends and customer requests.

- Look for fast die and slotting tool changes.

- Ensure the machine can handle different board grades and flute types.

- Evaluate the precision of slotting and creasing mechanisms.

4. Automation and Intelligent Controls

Automation is transforming the packaging industry. Modern flexo printer slotter die-cutters are equipped with PLC or CNC control panels, touchscreen interfaces, and independent servo motors for each unit. These features enable real-time monitoring, automatic fault detection, and remote diagnostics, reducing manual intervention and ensuring consistent output.

- Prioritize machines with user-friendly interfaces and digital controls.

- Consider integration with inline folder gluers, stitchers, and stackers for a seamless production line.

- Look for real-time monitoring and maintenance alert systems.

5. Energy Efficiency and Sustainability

As sustainability becomes a priority, energy-efficient designs and eco-friendly operations are increasingly important. Machines with low power consumption, efficient ink management, and minimal material waste help reduce environmental impact and operating costs.

- Choose equipment compatible with water-based inks and recyclable substrates.

- Assess the machine's energy consumption and waste reduction features.

- Ensure compliance with environmental regulations and industry standards.

How to Balance Flexibility and Cost

While it's tempting to choose the most advanced or fastest machine, it's essential to balance your investment with your actual production needs. Consider the following:

Customization vs. Standardization: If your business frequently produces custom packaging, prioritize machines with rapid changeover capabilities and flexible configurations. For standardized, high-volume production, focus on speed and reliability.

Total Cost of Ownership: Factors include not just the purchase price but also maintenance, energy consumption, and potential downtime. A slightly higher upfront investment in a reliable, efficient machine can yield significant savings over time.

Scalability: Choose equipment that can grow with your business, either through modular upgrades or integration with additional production lines.

Why Choose Giant as Your Carton Machinery Partner

At Giant, we understand that every packaging operation is unique. Our flexo printer slotter die-cutters are designed to address the real-world challenges faced by manufacturers worldwide. Here's why partnering with us is the smart choice for your business:

Advanced Technology: Our machines feature modular designs, dual gluing and stitching options, and energy-efficient servo drives. We support a wide range of box sizes and board types, ensuring you can meet any customer requirement.

Precision Engineering: Designed and assembled by experienced engineers, our equipment is known for its reliability, speed, and print quality. Whether you need high-speed production or intricate customization, we have the right solution.

Comprehensive Support: From initial consultation to post-installation service, we provide expert guidance, tailored training, and rapid-response technical support. Our global service network ensures that help is always within reach.

Sustainability Commitment: We prioritize eco-friendly production, offering machines compatible with water-based inks and recyclable substrates, and continually innovate to reduce energy consumption and material waste.

Proven Track Record: With installations across North America, Europe, Asia, and Africa, our reputation for quality and customer satisfaction speaks for itself. We hold CE certification and multiple industry patents, reflecting our commitment to excellence.

Conclusion

Selecting a Flexo Printer Slotter Die-Cutter is a multifaceted decision that requires careful analysis of your production needs, print quality standards, automation requirements, sustainability goals, and the reliability of your equipment partner. If you're seeking a solution that combines advanced technology, flexibility, and world-class support, we invite you to contact us at Giant and discover how our carton machinery can elevate your business to new heights.