How to Choose the Right Flexo Printer Slotter Die Cutter Machine for Your Packaging Line

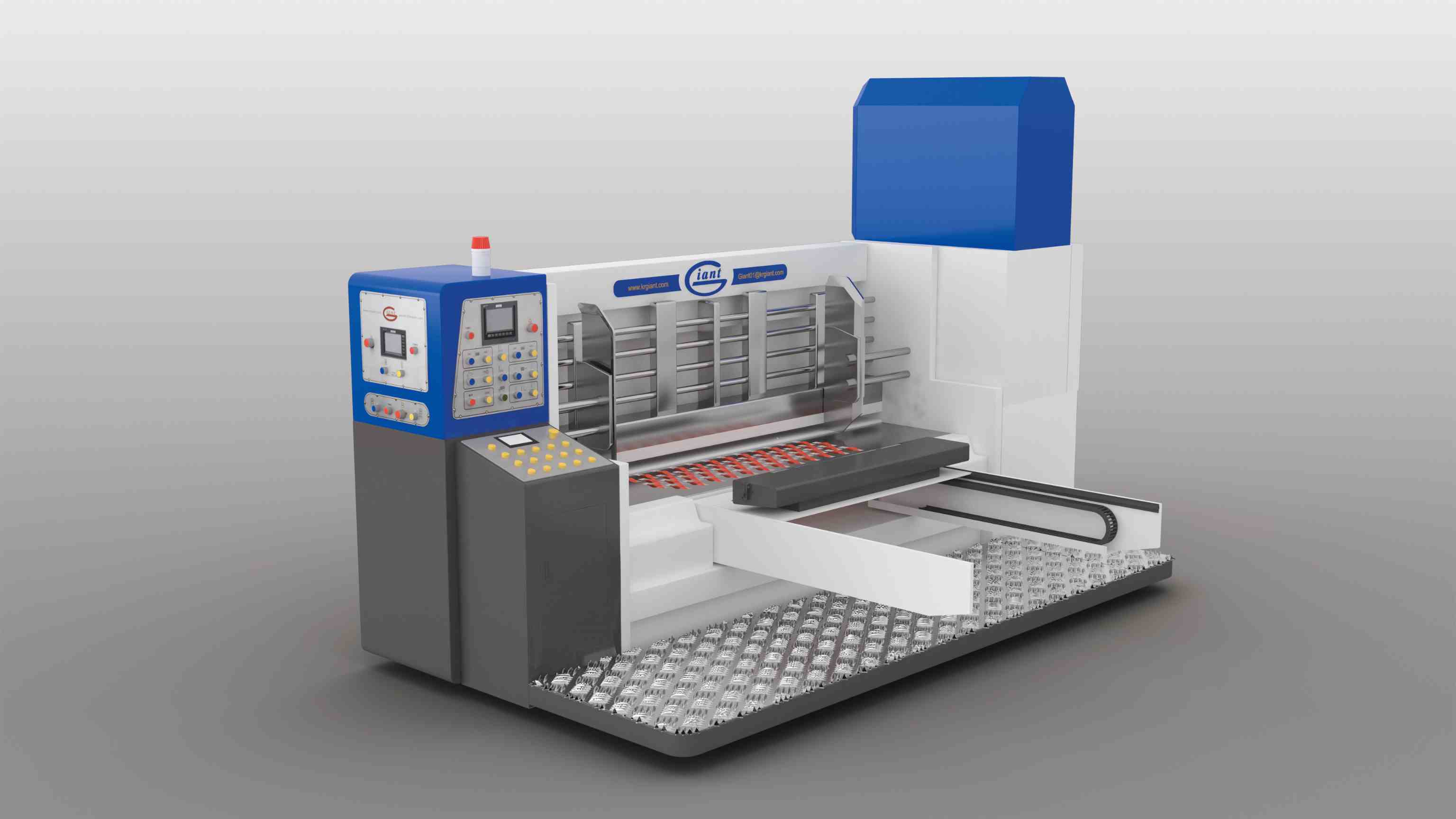

In the competitive world of packaging manufacturing, choosing the right equipment is essential for achieving high-quality output, operational efficiency, and cost-effectiveness. For businesses producing corrugated boxes, folding cartons, and pizza boxes, a flexo printer slotter die cutter machine serves as the backbone of their production line.

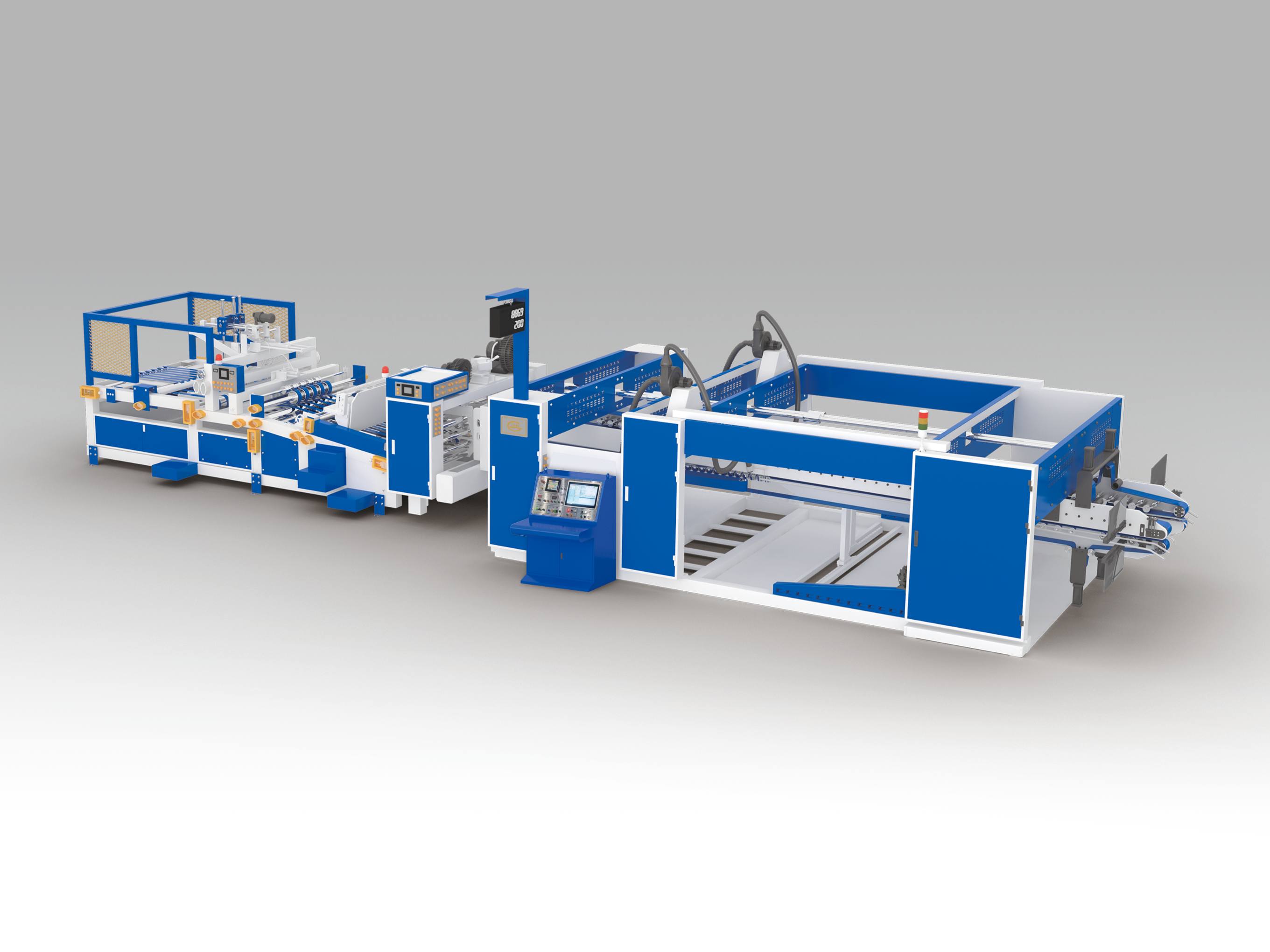

These machines combine flexographic printing, slotting, and die-cutting into a single integrated system, enabling high-speed production with accurate cuts and consistent print quality. Selecting the wrong machine can result in poor print output, increased waste, higher labor costs, and delays in delivery schedules.

This article provides a comprehensive guide to choosing the right flexo printer slotter die cutter machine, with insights on features, workflow optimization, substrate handling, and supplier evaluation to help manufacturers make informed decisions.

Why Choosing the Right Flexo Printer Slotter Die Cutter Matters

Impact on Production Efficiency

Production efficiency is directly tied to the machine's speed, precision, and ability to handle multiple processes seamlessly. A well-chosen flexo printer slotter die cutter machine reduces downtime, eliminates manual interventions, and ensures consistent throughput. Manufacturers producing high volumes of corrugated boxes, folding cartons, or specialty packaging benefit from faster turnaround times and reduced labor costs.

For example, integrated machines can combine printing and cutting in a single pass, reducing the handling steps required in separate printing and die-cutting processes. This improves overall efficiency and minimizes the risk of board damage during transfer between machines.

Cost and ROI Considerations

The upfront investment in a flexo slotter die cutter machine may appear significant. However, the long-term benefits in terms of reduced waste, faster production cycles, and superior print quality often outweigh the initial costs. Evaluating machines based on return on investment (ROI) ensures that the selected equipment supports both current production needs and future growth plans.

By investing in a high-performance machine from a reputable supplier like Giant, packaging manufacturers can achieve higher productivity, improved quality, and more sustainable operations.

Key Features to Consider

Selecting the right machine involves evaluating multiple factors to ensure it meets production and quality requirements.

Printing Speed and Capacity

High-speed printing is crucial for meeting production targets. When evaluating machines, consider maximum printing speed, ease of adjustment for single-color and multi-color jobs, and the ability to maintain print quality at high speeds. Some machines offer servo-driven motor control, which allows operators to fine-tune printing speed for complex designs while maintaining optimal output.

Substrate Compatibility

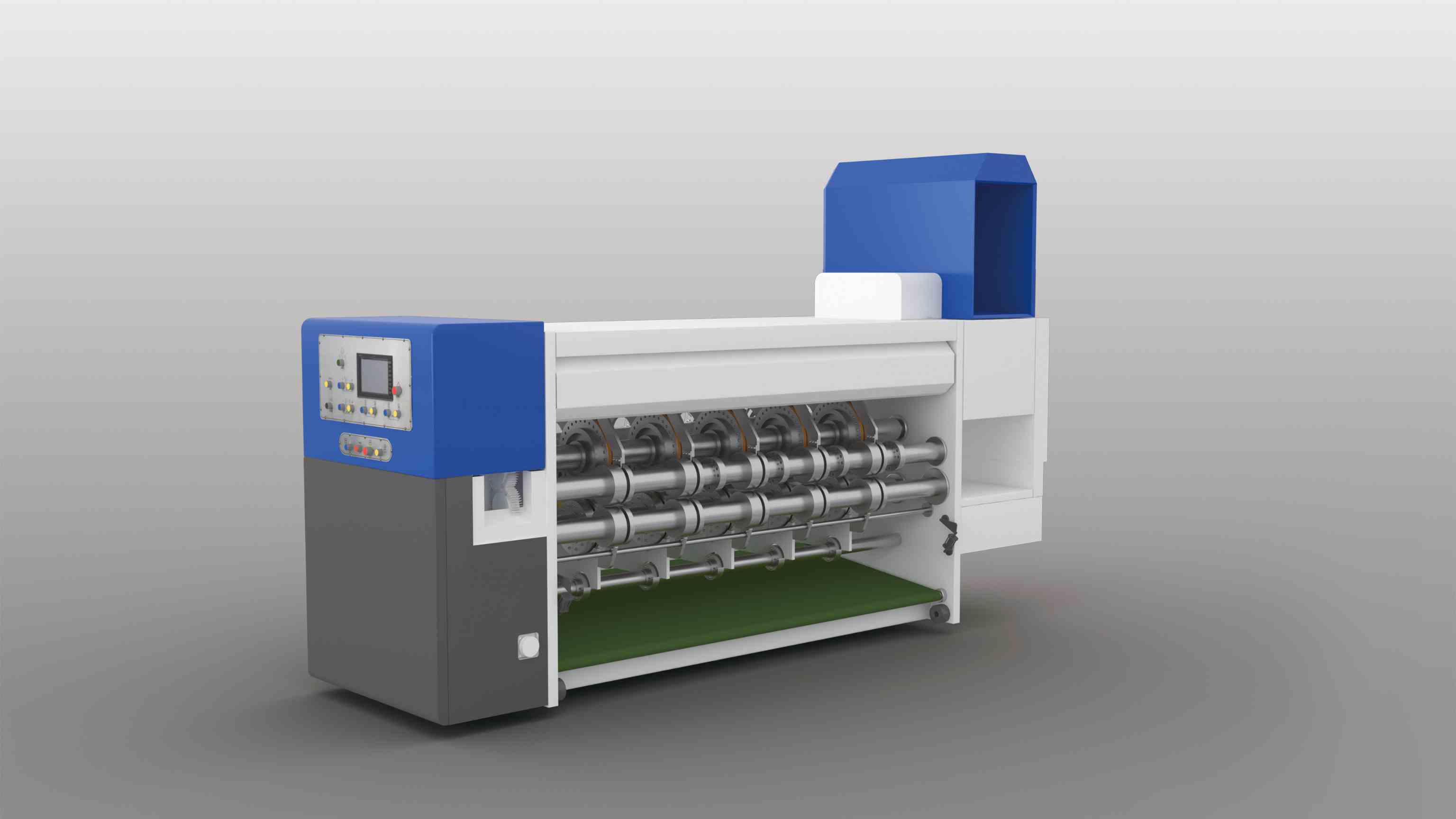

Corrugated boards vary in thickness, flute type, and surface texture. A reliable flexo printer slotter die cutter machine can handle different substrates, including E-flute, B-flute, and kraft liners, without compromising print clarity or causing board crushing. Machines with adjustable impression control and tension systems ensure even printing across various substrates.

Integrated Slotting and Die-Cutting

Inline integration of slotting and die-cutting ensures accurate folding, creasing, and cutting of boxes, which is critical for high-volume operations. Integrated systems reduce handling steps, minimize errors, and ensure repeatable results for both standard corrugated boxes and custom designs.

Manufacturers using integrated machines benefit from fewer setup times and higher production efficiency, as the machine can complete the full process in one continuous workflow.

Ink and Color Capabilities

Modern packaging often demands vivid, high-resolution graphics. Machines that support multi-color printing, water-based inks, and eco-friendly formulations ensure consistent color quality while meeting regulatory requirements. Proper anilox roller selection and plate maintenance are essential for precise ink transfer and minimizing color variation across the substrate.

Automation and Control Features

Advanced machines provide automated tension control, registration systems, and inline inspection cameras to monitor print quality in real time. Automation reduces operator errors, improves consistency, and allows faster changeovers between different production runs.

Comparing Integrated vs Separate Machines

While separate printing, slotting, and die-cutting machines can offer flexibility, integrated flexo printer slotter die cutter machines provide clear advantages:

- Streamlined workflow with reduced handling

- Improved registration and alignment

- Less substrate damage and material waste

- Faster production with fewer manual interventions

Tips for Evaluating Manufacturers and Suppliers

Selecting a machine also requires careful evaluation of manufacturers and suppliers. Key considerations include:

- Experience and Track Record – Choose suppliers with proven experience in corrugated flexo press manufacturing.

- After-Sales Support – Ensure spare parts availability, service support, and responsive customer service to reduce downtime.

- Training Programs – Operator training and technical support improve machine performance and reduce errors.

- Energy Efficiency and Sustainability – Eco-friendly machines lower operational costs and support environmental compliance.

- Customization Options – Ability to adapt machine features to specific production needs, such as specialized inks or substrates.

Conclusion: Making the Best Choice for Your Packaging Line

Selecting the right flexo printer slotter die cutter machine is critical for manufacturers aiming for high-quality output, efficiency, and long-term cost savings. By evaluating printing speed, substrate compatibility, integrated features, ink capabilities, automation, and supplier reliability, manufacturers can make an informed decision that supports both current production and future growth.

For packaging companies seeking a reliable, high-performance solution, Giant's flexo printer slotter die cutter machines provide integrated printing, slotting, and die-cutting capabilities designed for corrugated boxes, pizza boxes, and other folding carton applications. With advanced automation, eco-friendly inks, and consistent print quality, Giant machines help businesses increase productivity, minimize waste, and maintain a competitive edge in the packaging industry.