The Box Maker's Certificate: Your Assurance of Corrugated Packaging Quality

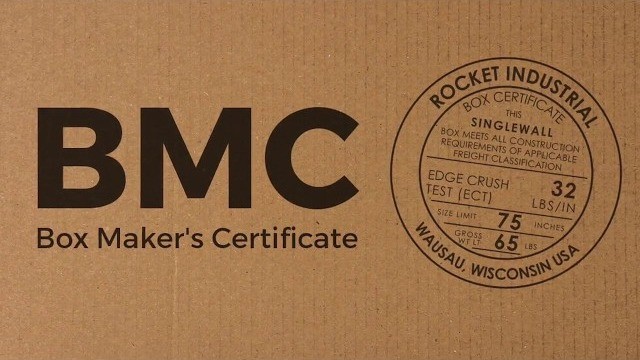

The Box Maker's Certificate (BMC) is the small circular or rectangular stamp you often see on corrugated boxes. Far from being just a logo, it proves that the box meets strict strength, size, and compliance standards under Rule 41. Whether for domestic shipping or international export, the BMC is your assurance of packaging quality, safety, and legal compliance.

The Regulatory Backbone: American Railroad Rule 41

The primary impetus behind the BMC's existence is American Railroad Classification Rule 41. This regulation dictates the requirements for transport packaging within the U.S. domestic market. While its official purview is limited to the United States, the influence of Rule 41 extends far beyond its borders. Many international markets, driven by stringent logistics regulations, customer demands, or established industry norms, often require BMC compliance for imported goods. This global acceptance underscores the BMC's role as a universally recognized benchmark for corrugated packaging quality.

Types of Box Maker's Certificates

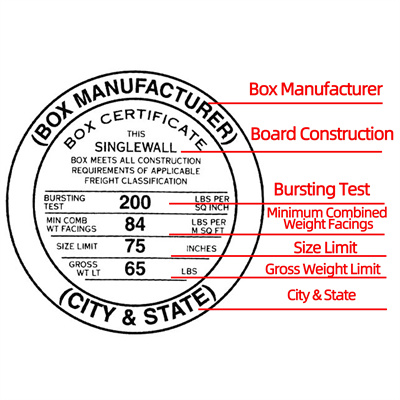

While Rule 41 primarily mandates a circular format, rectangular BMCs are also occasionally utilized. The three principal types of BMCs reflect different testing methodologies for assessing a box's strength:

- Bursting Strength Certificate (BST): This certificate indicates the maximum force, measured in pounds per square inch (psi), that a board can withstand before rupturing. Historically, BST was the more common measure and remains a preferred choice for export packaging due to its widespread recognition and historical use.

- Edge Crush Test Certificate (ECT): The ECT measures the edgewise compressive strength of corrugated board, indicating its resistance to crushing. This test is often favored for its direct correlation to a box's stacking strength.

- Puncture Resistance Certificate: While less common for general shipping, this certificate is used for specialized applications where resistance to puncture is a critical factor.

When it comes to selecting the appropriate BMC, a clear hierarchy applies:

- Customer Specifications: Always prioritize and adhere to any specific BMC type requested by your customer.

- Rule 41 Updates: In the absence of specific customer instructions, consult the latest updates to Rule 41 to determine the most suitable format.

- Export Preferences: For goods destined for international markets, the Bursting Strength Certificate (BST) is often the preferred choice due to its established industry recognition and historical prevalence.

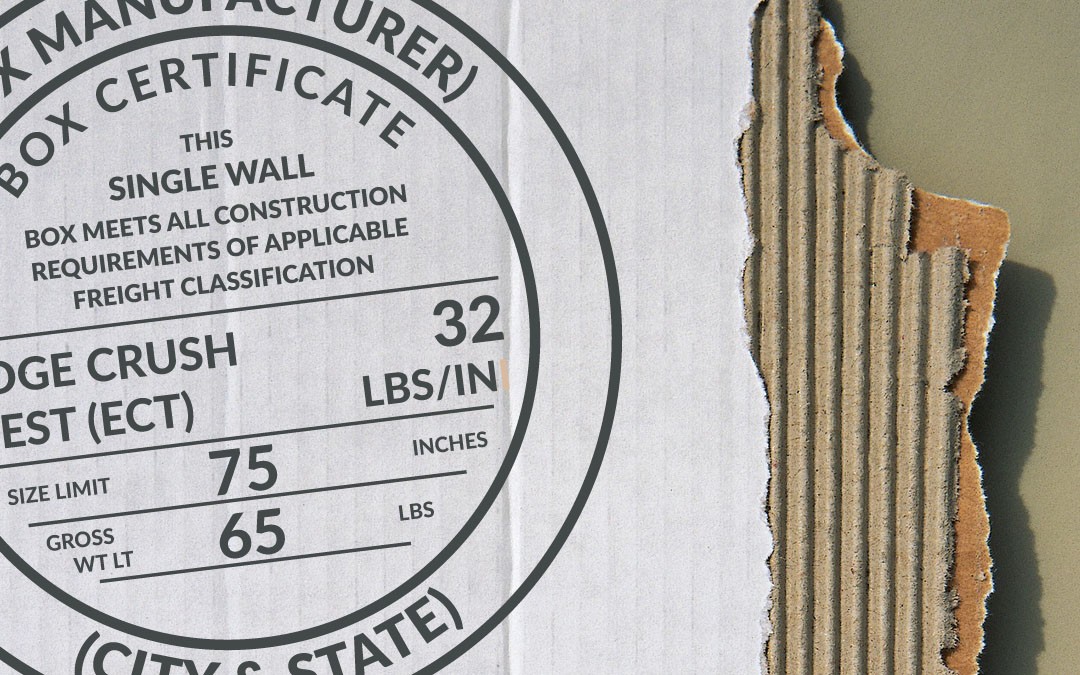

Key Numbers on the BMC Explained

Two critical components of the BMC are the maximum size limit and the strength requirements.

Maximum Size Limit: Rule 41 defines the maximum size limit as the sum of the box's external length, width, and height. A common misinterpretation involves doubling this sum; it's crucial to calculate this value accurately to avoid non-compliance.

Standard vs. Actual Values: The values listed on the BMC, as per Rule 41, represent minimum mandatory requirements. This means the actual strength data of the box must meet or exceed these specified values. The data printed on the BMC is legally binding and can be used as a basis for quality inspections. If actual test results fall short of the printed specifications, it can lead to significant compliance risks and potential liabilities. To mitigate such risks, it is generally advisable to use the standard values established by the regulations, ensuring a buffer for potential variations.

Common Packaging Challenges

Choosing the correct strength rating for your packaging involves a careful balance between weight and dimensions. Both must comply with the regulation's requirements.

Consider this example: an item weighing 22kg (49 lbs) with combined dimensions of 160cm (63 inches). While a single-wall box rated for 50 lbs might seem sufficient for the weight, it would be inadequate for the size constraints. In this scenario, a single-wall box rated for 65 lbs would be necessary to meet the size limit stipulated by Rule 41.

However, this adherence to regulations can sometimes lead to "over-packaging," particularly for lightweight, bulky items. For instance, a box with a total dimension of 110cm but only weighing 20 lbs would, by strict adherence to Rule 41 based on size, require a box rated for 140 lbs. This can result in excessive material usage and unnecessary costs. In such cases, it becomes imperative to explore alternative packaging solutions that maintain compliance without incurring excessive material expenditure.

Placement and Size Rules for the BMC

Even the size and placement of the BMC are regulated by Rule 41. Adhering to these guidelines is crucial for ensuring compliance with industry standards and avoiding potential issues.

Risks of Ignoring the BMC

Failure to properly design, print, or utilize the BMC in accordance with Rule 41 can lead to severe non-compliance issues. This can manifest as significant quality disputes, product damage, and even legal ramifications, particularly in international export markets where regulations can be even more stringent.

The packaging industry is a highly technical domain demanding a thorough understanding of material science, intricate logistics, and complex regulatory frameworks. Diligent adherence to BMC requirements is not merely a formality; it is fundamental to ensuring product protection, maintaining legal compliance, and ultimately, achieving customer satisfaction.

Conclusion

The Box Maker's Certificate (BMC) is more than just a stamp printed on corrugated packaging—it is a binding quality assurance mark that verifies compliance with Rule 41 standards for strength, size, and performance. By understanding what the BMC means, how to interpret its values, and why it is required in both domestic and export logistics, businesses can ensure:

- Reliable protection of goods during transit

- Full compliance with regulatory requirements

- Reduced risk of disputes, returns, and penalties

- Greater trust from customers and supply chain partners

For manufacturers, shippers, and exporters, paying close attention to the BMC is not just a technical detail—it is a strategic step in building credibility, reducing costs, and safeguarding product integrity.

Looking to upgrade your packaging line with machines that meet BMC and international quality standards? Giant offers advanced flexo printers, folder-gluers, and converting solutions that ensure every box leaving your factory is strong, compliant, and future-ready.

FAQ: Box Maker's Certificate in Packaging

1. What is the Box Maker's Certificate (BMC) on a box?

It is a printed stamp (circular or rectangular) that certifies the corrugated box meets Rule 41 standards for strength, size limits, and material quality.

2. What is the difference between BST and ECT in the BMC?

- BST (Bursting Strength Test): Measures resistance to rupture under pressure (commonly used for exports).

- ECT (Edge Crush Test): Measures stacking strength and resistance to edge compression. Both indicate box durability but are based on different testing methods.

3. Do all export cartons require a BMC?

Yes. Most international shipments require BMC compliance as part of legal and logistics standards, particularly in the U.S. and markets influenced by Rule 41.

4. Who issues the Box Maker's Certificate?

The box manufacturer is responsible for testing, certifying, and printing the BMC on the carton. It is a legal declaration of compliance.

5. What happens if a box fails to meet BMC standards?

If the actual strength or size tolerance does not match the printed BMC:

- Shipments may be rejected at customs or by carriers

- Companies may face compliance risks, penalties, or product damage claims

- It can negatively impact brand credibility

6. Where should the BMC be placed on the box?

Rule 41 requires the BMC to be printed on a visible panel of the box, in a standardized size and format, to ensure quick inspection during shipping and handling.