Applications of Flexo Printer Slotter Die Cutter Machines in Modern Packaging Industry

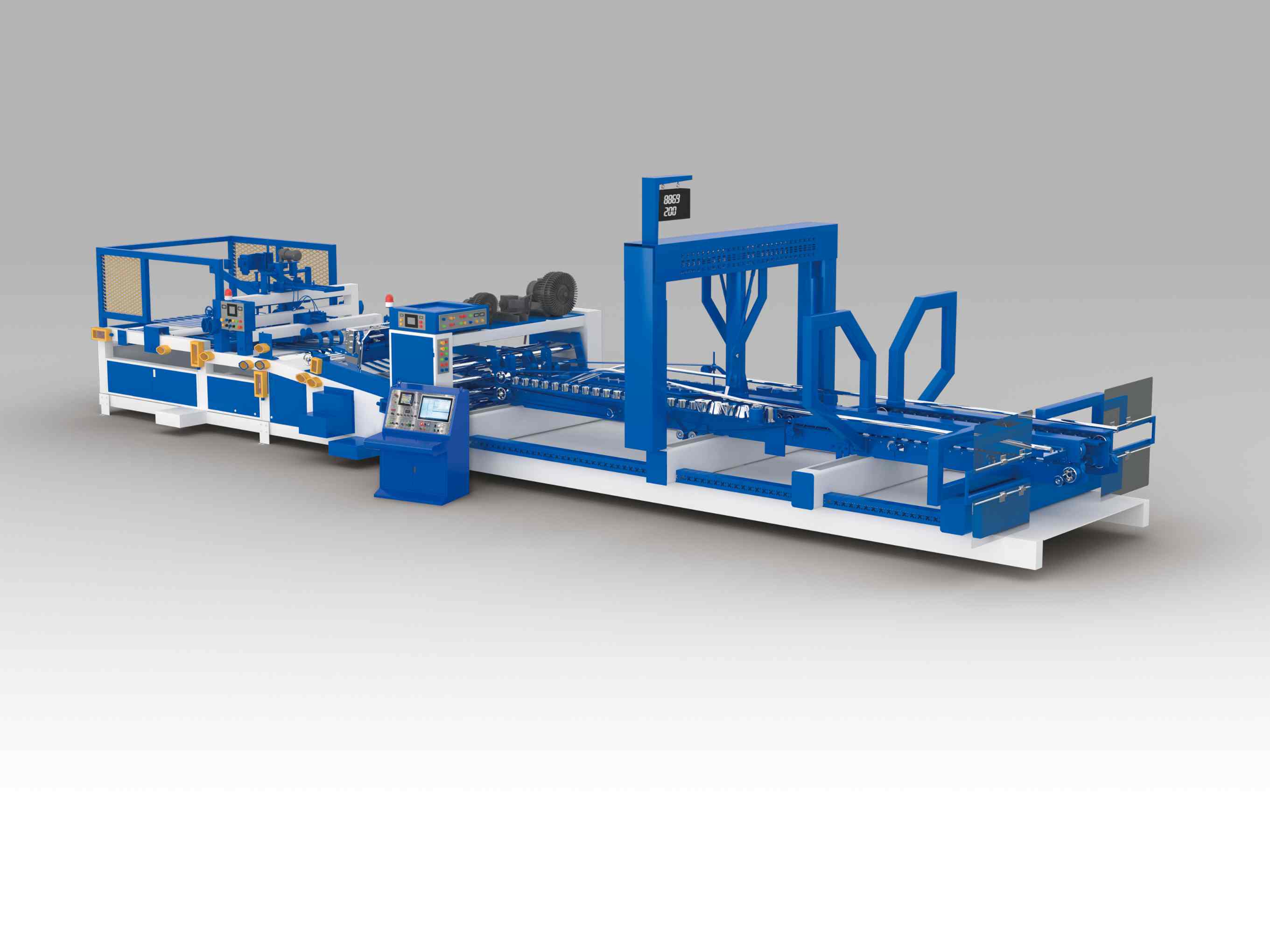

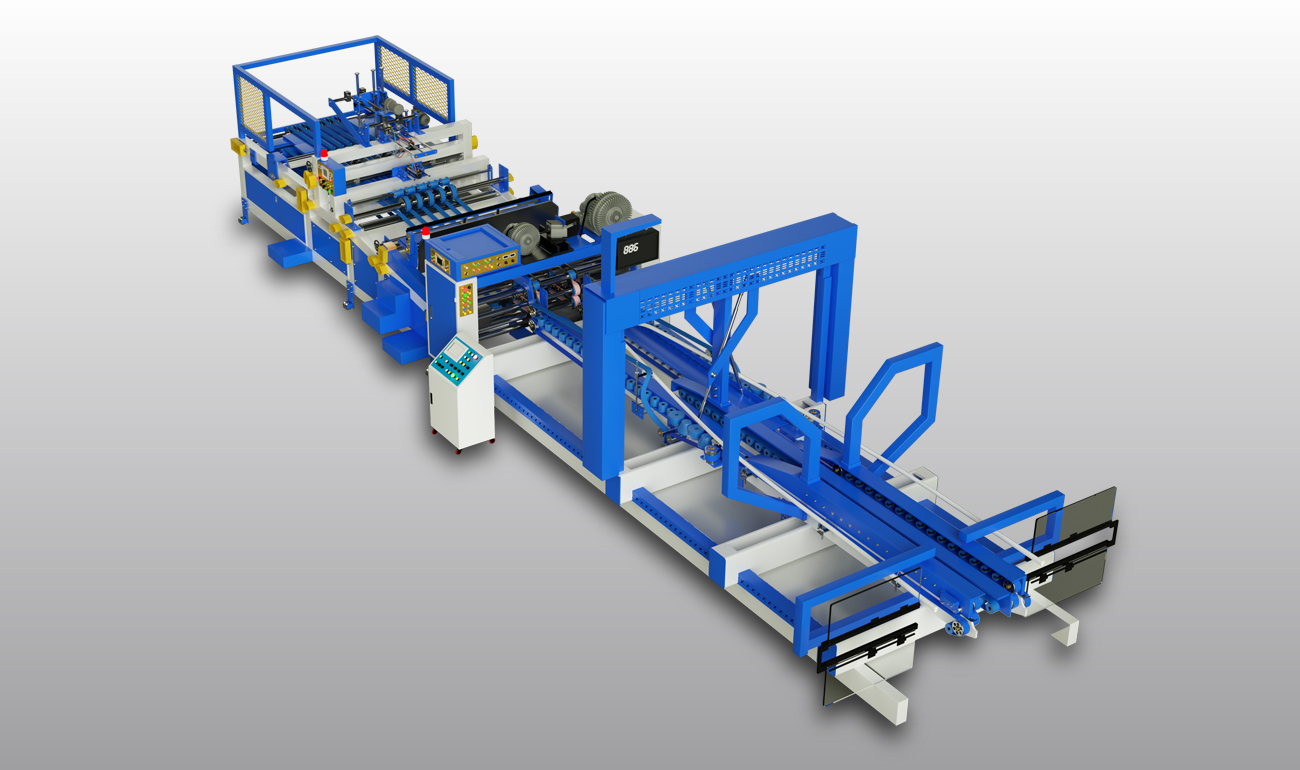

In today's highly competitive packaging industry, efficiency, precision, and customization are paramount. The flexo printer slotter die cutter machine has emerged as a pivotal technology that integrates multiple processes—flexographic printing, slotting, die cutting, folding, and gluing—into a single streamlined workflow. This all-in-one machine is revolutionizing how corrugated packaging is produced, enabling manufacturers to meet diverse market demands with speed and quality. Its wide-ranging applications cover essential packaging types such as pizza boxes, shipping carton boxes, and food packaging cartons, among many others.

Core Functionalities of Flexo Printer Slotter Die Cutter Machines

These machines perform several critical tasks in one continuous process:

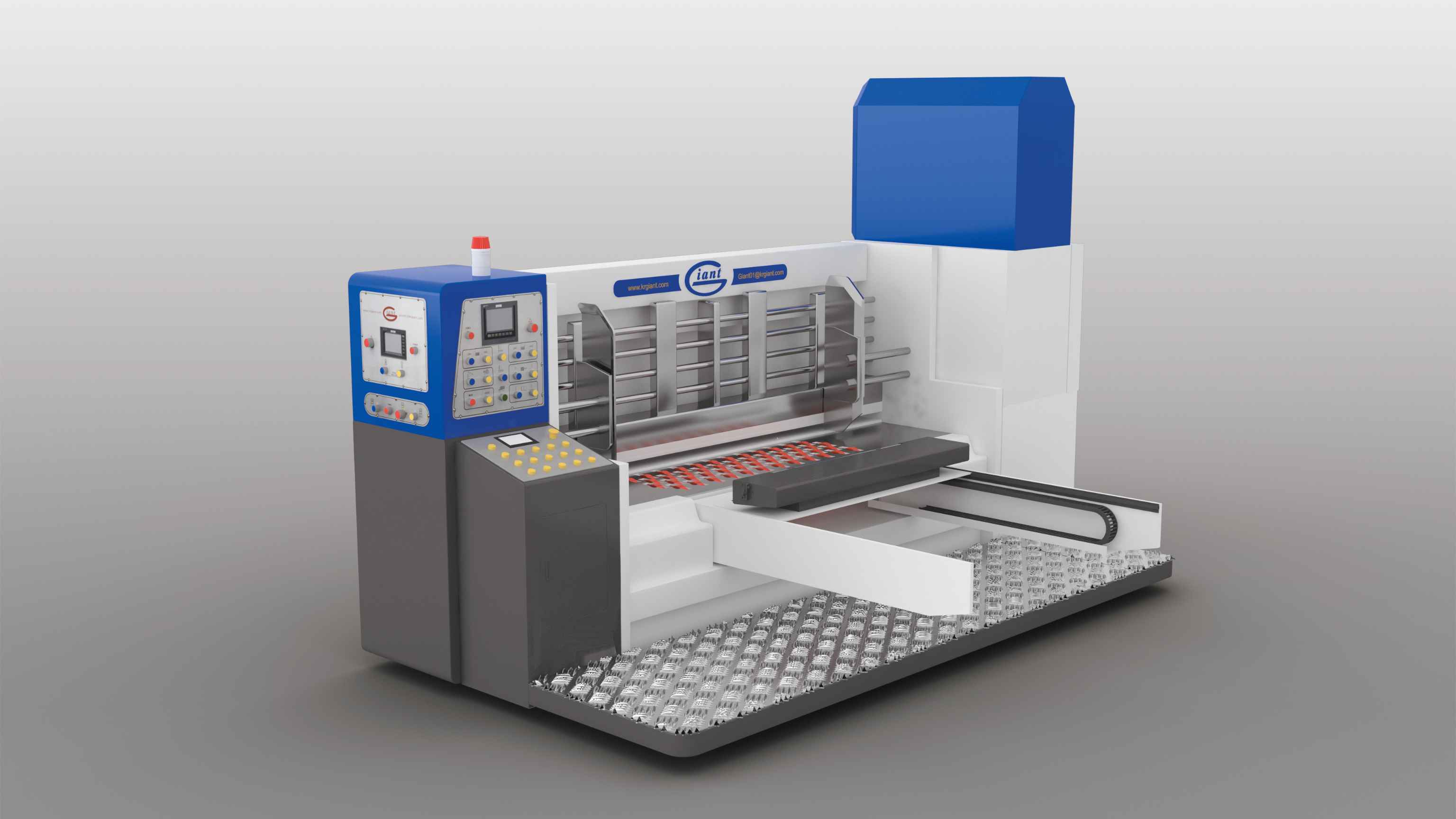

Flexographic Printing: Uses flexible plates to print high-quality, vibrant graphics on corrugated board, essential for brand visibility and product information.

Slotting: Creates precise slots and scores that allow the corrugated board to be folded easily and accurately.

Die Cutting: Cuts the board into custom shapes or adds special features like ventilation holes or windows.

Folding and Gluing: Assembles the carton into its final form with sharp creases and secure adhesion.

Automation and Control: Modern machines feature computerized systems for precision, speed, and ease of operation, minimizing waste and downtime.

Applications in the Packaging Industry

Pizza Boxes

Pizza boxes require sturdy construction to maintain heat and protect the contents during delivery, along with attractive printing for branding. The flexo printer slotter die cutter machine excels in producing pizza boxes by combining high-quality flexo printing with precise slotting and die cutting to create boxes of various sizes and designs. This machine allows manufacturers to customize box styles, incorporate ventilation holes, and print vibrant logos or promotional graphics, all in one efficient process. The ability to handle complex shapes and quick changeovers makes it ideal for pizza box production, where both speed and customization are critical.

Shipping Carton Boxes

Shipping cartons must be durable and tailored to different product dimensions. Flexo printer slotter die cutter machines enable manufacturers to produce custom-sized shipping cartons with clear printed handling instructions, barcodes, and branding. The slotting and die-cutting functions ensure that cartons fold perfectly for efficient packing and transport. This versatility supports industries ranging from e-commerce to electronics, where protective packaging is essential. The machine's automation reduces manual labor and speeds up production, which is vital for meeting large-volume shipping demands.

Food Packaging Cartons

Food packaging demands hygienic, safe, and visually appealing cartons. Flexo printer slotter die cutter machines produce food packaging cartons that comply with health standards while offering excellent print quality for branding and product information. Die-cutting capabilities allow for ventilation holes, windows, or custom shapes that enhance product visibility and freshness. The integrated gluing and folding processes ensure cartons are leak-resistant and structurally sound, critical for fresh produce, frozen foods, and dry goods packaging.

Additional Key Applications

Retail and Point-of-Sale Displays: These machines create eye-catching corrugated displays with custom printing and intricate die cuts, helping products stand out on shelves.

Pharmaceutical and Electronics Packaging: Precision die-cutting and slotting produce protective cartons with exact dimensions and specialized inserts.

Cosmetics and Luxury Goods Boxes: High-quality flexo printing combined with unique die-cut designs enhances the premium look and feel of packaging.

E-commerce Packaging: Customizable shipping and product boxes that combine durability with brand promotion, essential for online retailers.

Advantages Driving These Applications

Integrated Production: Combining printing, slotting, and die cutting reduces setup times and manual handling, leading to faster turnaround.

Customization and Flexibility: Machines can quickly switch between different box sizes and designs, accommodating short runs and bespoke orders.

High Print Quality: Flexo printing delivers sharp, vibrant images that maintain brand integrity.

Material Efficiency: Precise cutting and slotting minimize waste, reducing costs and environmental impact.

Automation: Advanced control systems improve accuracy, reduce labor costs, and enable real-time monitoring and adjustments.

Why Giant Is Your Ideal Partner for Flexo Printer Slotter Die Cutter Machines

When selecting equipment to elevate your packaging production, Giant offers unmatched expertise and innovation tailored to your specific needs. Unlike generic suppliers, Giant's machines are engineered with a deep understanding of the practical challenges and evolving demands of the packaging industry.

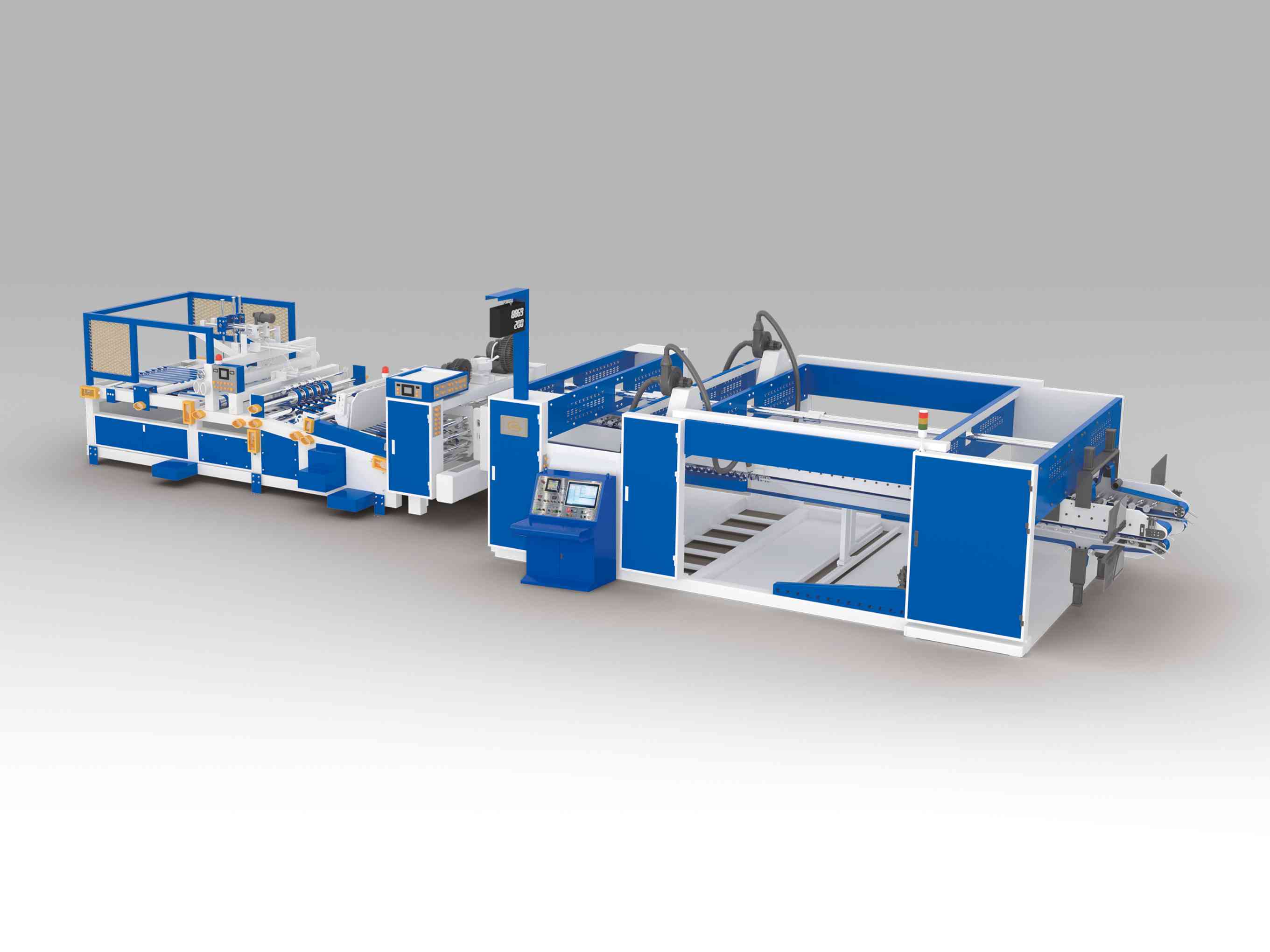

Technological Excellence: Giant's flexo printer slotter die cutter machines feature dual gluing and stitching functions, allowing you to choose or combine bonding methods for enhanced carton strength and versatility. This capability is especially valuable for heavy-duty shipping cartons or specialty packaging requiring extra durability.

Large Format Capacity: With the ability to process oversized corrugated sheets (up to 1600 x 3200mm), Giant machines accommodate large boxes and complex designs that many competitors cannot handle, making them ideal for industries requiring bigger or multi-layered packaging.

Precision and Reliability: Giant integrates independent creasing sections and advanced servo drives to ensure sharp folds and consistent quality, even with thick or multi-ply corrugated boards. This precision reduces errors and waste, boosting your production efficiency.

Global Quality Standards: All Giant machines hold national patents and CE certification and have passed audits by BV and SGS, reflecting their compliance with international quality and safety standards. Their machines have been exported worldwide, including to North America, Europe, and Southeast Asia, proving their reliability in diverse markets.

Customer-Centric Support: Giant provides comprehensive pre-sale consultation, customized machine configuration, and responsive after-sales service. Their global service network ensures that technical assistance and maintenance support are readily available, minimizing downtime and protecting your investment.

Sustainability Focus: Giant's equipment supports eco-friendly production by enabling the use of water-based inks and recyclable materials, aligning with growing environmental regulations and consumer expectations.

By choosing Giant, you gain a partner committed not just to selling machinery but to helping your business grow sustainably through advanced technology, tailored solutions, and dedicated service.

Conclusion

The flexo printer slotter die cutter machine is a cornerstone technology in the modern packaging industry, offering unparalleled integration of printing, cutting, and assembly processes. Its applications span a broad spectrum—from pizza boxes and shipping cartons to food packaging cartons and beyond—enabling manufacturers to produce high-quality, customized packaging efficiently and cost-effectively.

This machine's ability to handle diverse packaging needs with precision and speed makes it indispensable for businesses aiming to enhance brand image, reduce waste, and meet fast-changing market demands.

If you want to future-proof your packaging production and deliver superior products to your customers, Giant is ideal for you. Please feel free to contact us at inquiry@krgiant.com for more information about our product packing solutions.