At Giant, we specialize in providing a full range of corrugated packaging machinery designed to improve efficiency, precision, and automation in box production. Whether you're looking for high-speed printing machines, folder gluer stitcher systems, or versatile flexo printer slotter die cutters, we deliver innovative solutions tailored for modern packaging needs.

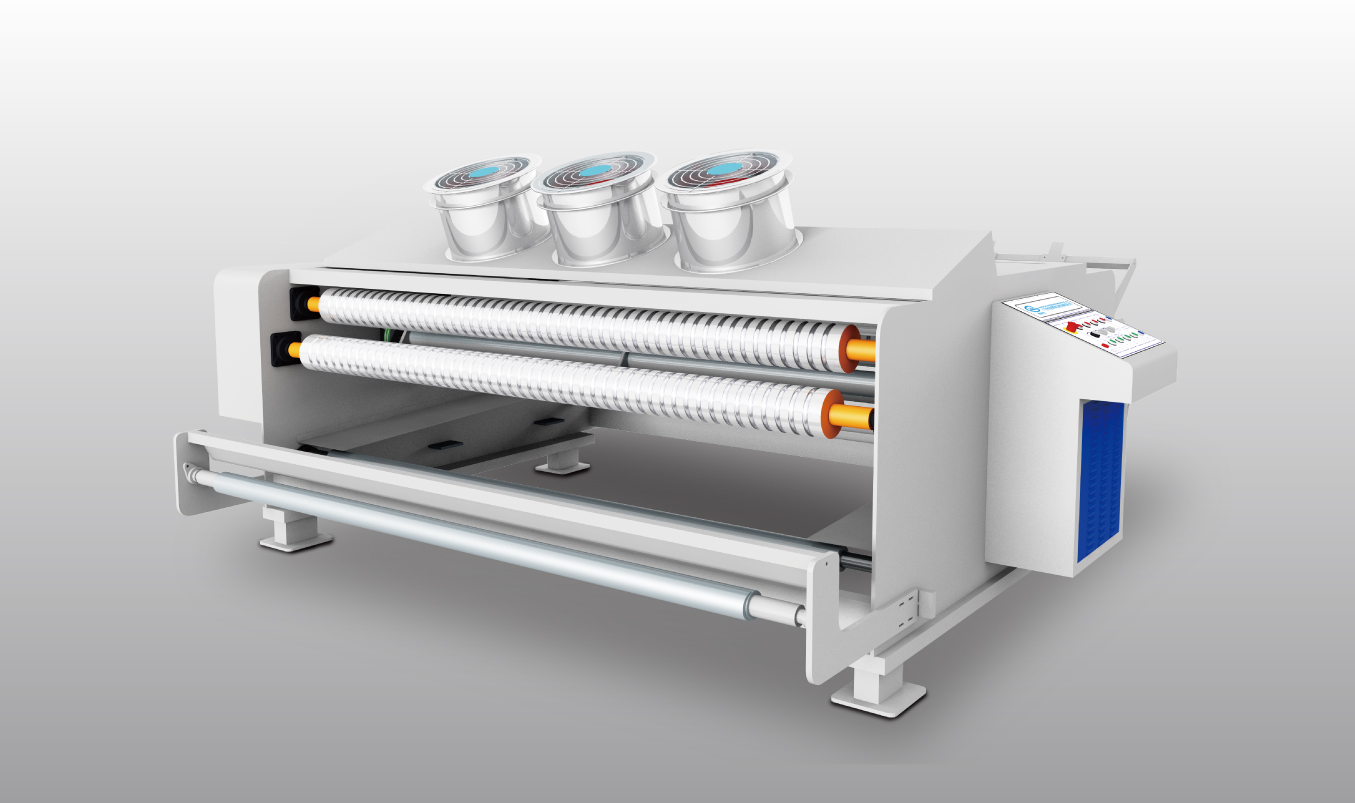

Printing Machine

Our printing machines for corrugated cardboard are built for high-quality, multi-color printing with precise registration. They're ideal for custom branding, barcode printing, and product labeling. Designed for durability and ease of use, these machines offer outstanding performance in industrial settings.

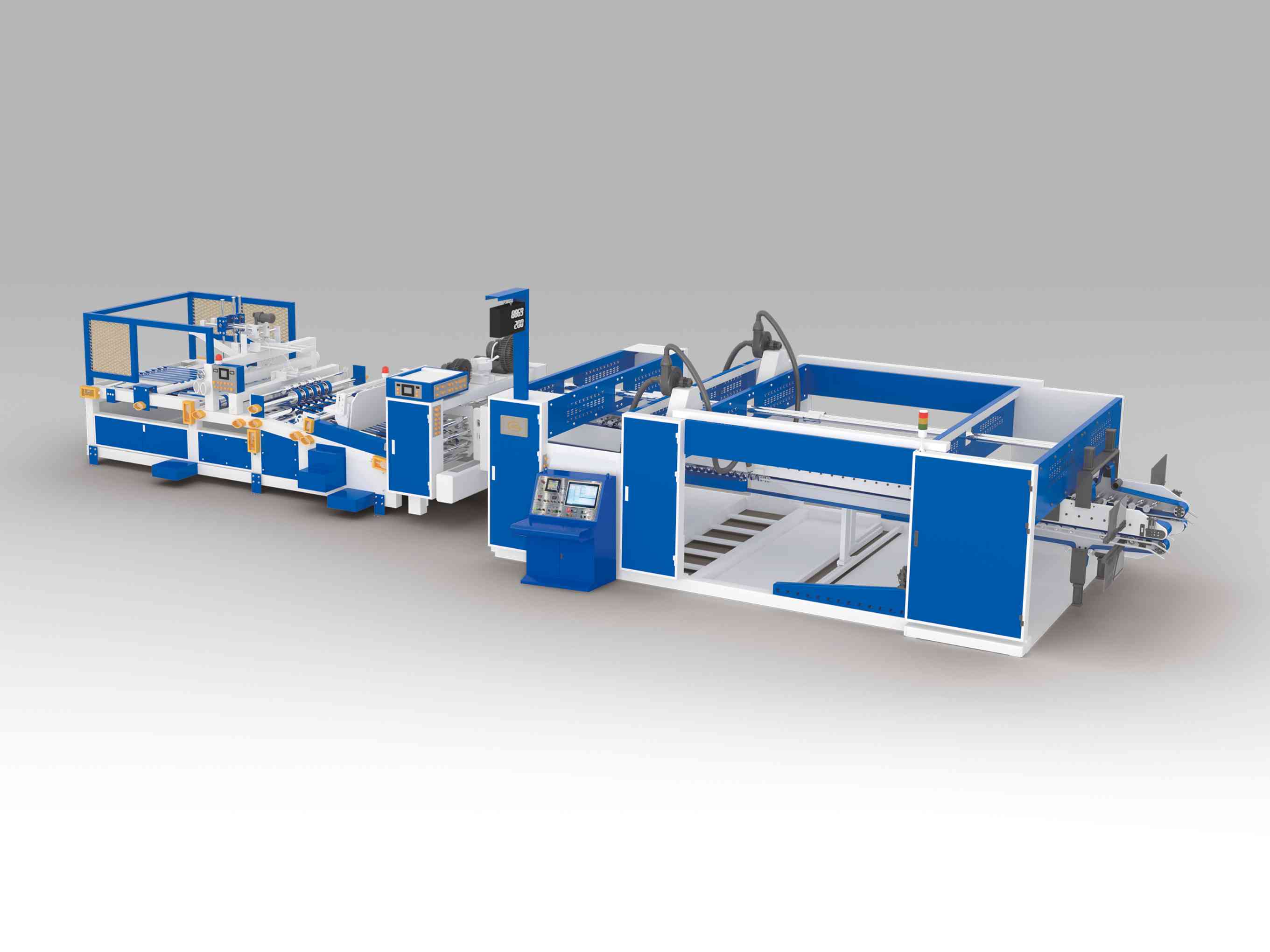

Flexo Printer Slotter Die Cutter & Folder Gluer/Stitcher Counter Ejector

This multi-function flexo machine integrates printing, slotting, die-cutting, folding, gluing/stitching, and counter-ejection in a single automatic line. Perfect for businesses seeking seamless production and reduced labor costs.

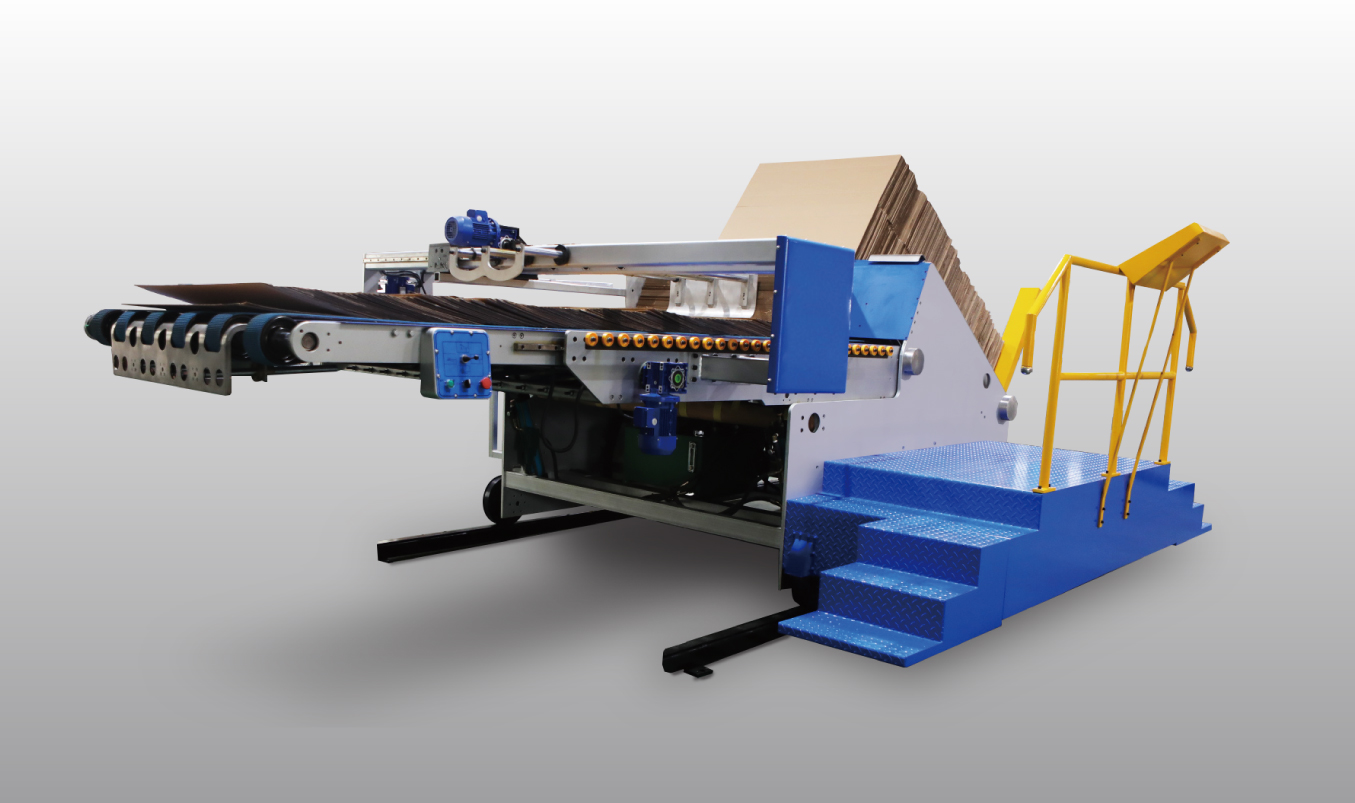

Automatic Folder Gluer / Stitcher Counter Ejector

Designed for automated box folding and stitching, this machine ensures high-speed production with consistent accuracy. It's a must-have for large-volume corrugated box manufacturing plants.

Other Machines

We also offer a wide range of corrugated box making machines and auxiliary equipment to complement your production line. From pre-feeders, rotary die cutter, vibrator, to hydraulic auto stacker, Giant provides a complete solution for your packaging business.

Why Choose Giant?

Giant is committed to quality engineering, efficient automation, and customer-focused innovation. We offer:

- Custom machine configuration based on production requirements

- Durable and reliable build for long-term use

- Professional technical support and after-sales service

With years of experience and global partnerships, Giant is your trusted packaging equipment supplier.